BigJimFish

Written: Oct 8, 2020

Table of Contents:

– Background

– How a Proof Carbon Wrapped Barrel is Made

– Proof Carbon Barrel Cooling

– Carbon Fiber Barrel Harmonics

– Summary and Conclusion

Background:

Proof research is an interesting conglomeration of companies in the same way, and for the same reason, that their carbon wrapped barrels are an interesting conglomeration of technologies. At this time, Proof research includes: Advanced Barrel Systems (carbon wrapped barrels), Jense Precision (custom rifles), Lone Wolf Rifle Stocks, Lawrence Rifle Barrels, and Performance Polymer Solutions (aerospace composites). The company therefore produces not just the carbon wrapped barrels they are well known for, but also conventional steel barrels, stocks, rifles, and composites for the aerospace industry which are used in jets and satellites.

You could say that Proof started making carbon wrapped barrels in 2000, and Advanced Barrel Systems did, but Proof is now on its 3rd major generational change in carbon wrapped technology, so the product today is quite different from that in 2000 since all the people and technology necessary to make today’s Proof carbon wrapped barrel were not yet together at that time.

Early generations of Proof barrels, as well as some other carbon wrapped barrel maker’ products, had, and have, a reputation for dramatic shifts in POI as the barrel heats up, slow barrel cooling, and even for the bonds between the steel liner and the carbon wrapping failing such that you can spin the carbon on the steel liner like a wheel on an axle. My own first experience with Proof came from one of their earlier generation barrels. In 2010 my brother picked up a used rifle chambered by a very well respected smith with an earlier generation Proof barrel on it. Neither of us could ever get that rifle to shoot to our standards. It wasn’t terrible, generally between 1-2moa, but it never went sub moa. It just wasn’t custom rifle good. There was suggestion that the barrel might be shot out, though I sort of doubted a sub 7lb .308 with no compensator likely to have seen such use. My brother re-barreled and sold the gun and I made a mental note to be skittish about carbon fiber barrels as that seemed the most likely source of the problems to me.

A few years later, at SHOT 2014, the Proof people appeared to me to be re-launching their product. I presume this was when the 3rd gen stuff started. We talked about the issues their barrels had had in the past and they were confident to have solved them to be producing a superior new barrel. Over the next few years the reports I started to hear about them were positive and, in 2018, one came my way as part of the review of an excellent lightweight hunting rifle from Mesa Precision Arms. That barrel shot great and some uniqueness in how exactly it did that would start me on a harmonics investigation of Proof’s carbon fiber barrels which would eventually result in this review.

How a Proof Carbon Wrapped Barrel is Made:

People have been trying to combine carbon and steel in a barrel for a long time, frequently unsuccessfully. Carbon and steel fundamentally expand at different rates when heated. This -the very directional properties of Carbon, the non-directional properties of steel, and the yet different properties of bonding agents involved – all combine to make building a carbon wrapped barrel quite difficult. Different companies have taken entirely different paths when it comes to carbon barrel technology and construction. This review of Proof’s products is therefore only applicable to their products. You should consider each different maker’s carbon barrel products to be entirely different technologies and judge each separately. I have not tested any other makers’ carbon barrel products and have no idea how they behave.

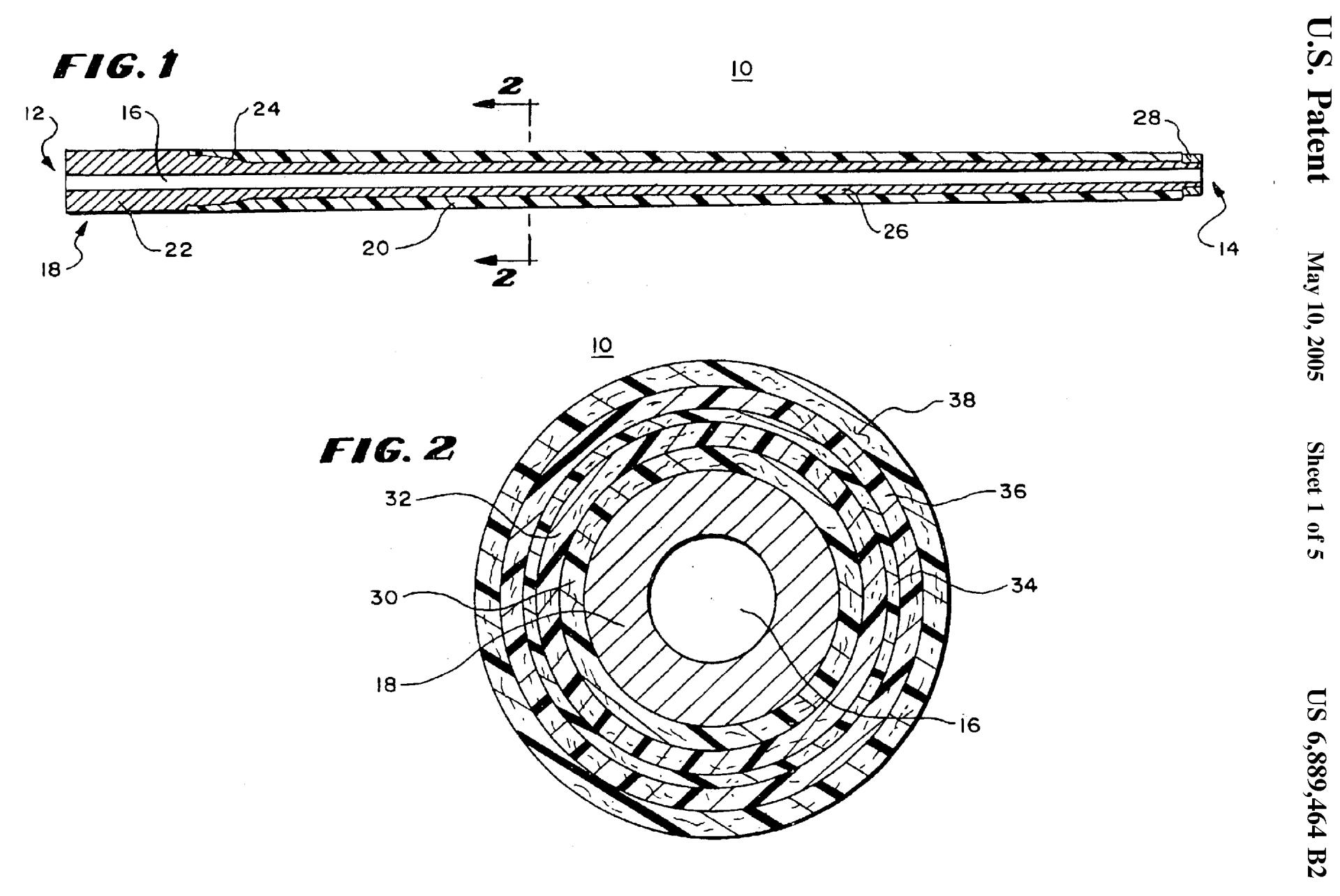

When making a carbon composite barrel you are trying to get the lower weight of the carbon to make the barrel lighter, its incredible tensile strength to minimize bore expansion under heat and pressure, its excellent conductivity along the direction of the fiber to help with cooling, and the stiffness possible when carbon fiber is properly combined with a matrix to form a composite. These are all great properties but carbon is not near flame or abrasion resistant enough for the whole barrel to be made of it, so you still have to have a steel liner inside the barrel. Though the steel liner is thick enough to contain the pressure from firing itself, if the carbon composite separates from the liner the barrel will behave quite erratically, so it is paramount that it does not. It is also important that the carbon composite is able to handle the high temperatures, vibrations, and thermal cycling it will be exposed to. To this end, Proof has a number of patents related to the wind angles and wind layering of the carbon as well as some related to the resin bonding agent.

The practice of producing a carbon barrel looks deceptively simple when compared to research it takes to understand exactly how and why it is being done that way. What looks like wrapping a carbon fiber filament soaked in glue around the steel barrel liner is actually seven different layers of differently angled carbon wraps of a filament soaked in a resin specifically formulated for conductivity and thermal stability. If those specifics aren’t just right, the barrel walks when heated and perhaps even delaminates. What you see on the factory floor appears quite simple however. To make a carbon composite barrel you first make a finished conventional steel barrel blank in straight contour. In Proof’s case, these are cut rifled blanks. Next, you contour everything but the chamber and muzzle section down very thin. You then wrap carbon filament soaked in your special resin really tight on a giant spinning wheel looking machine in just the right special pattern. Once the resin cures, you heat treat it and then sand it down to the final contour. This leaves the pretty exposed mottled carbon pattern you associate with Proof carbon fiber barrels. In this pattern you can see some of the angle variation in the winds as well as that there is a great deal of carbon and not a whole lot of resin left once all is said and done.

Proof Carbon Barrel Cooling:

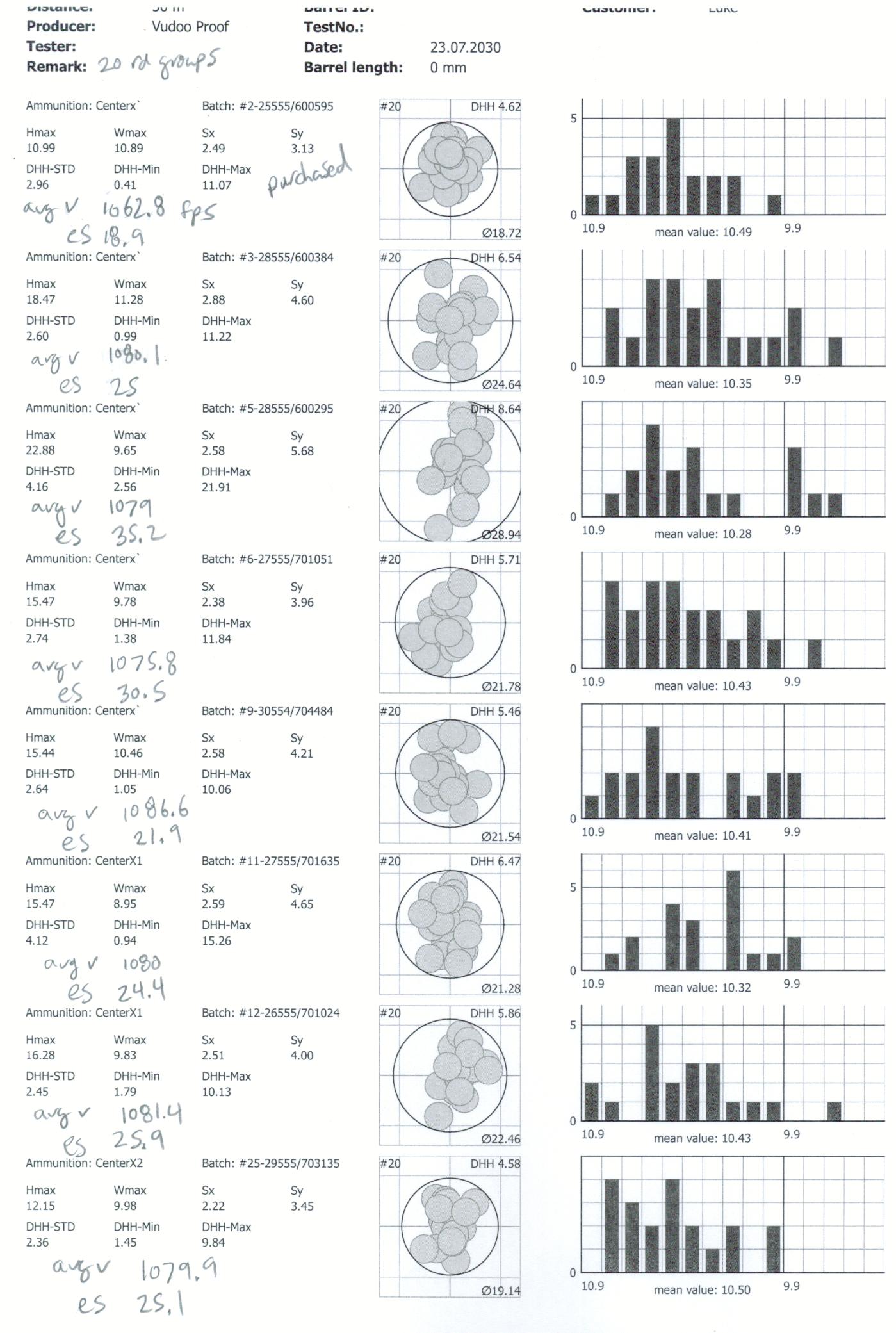

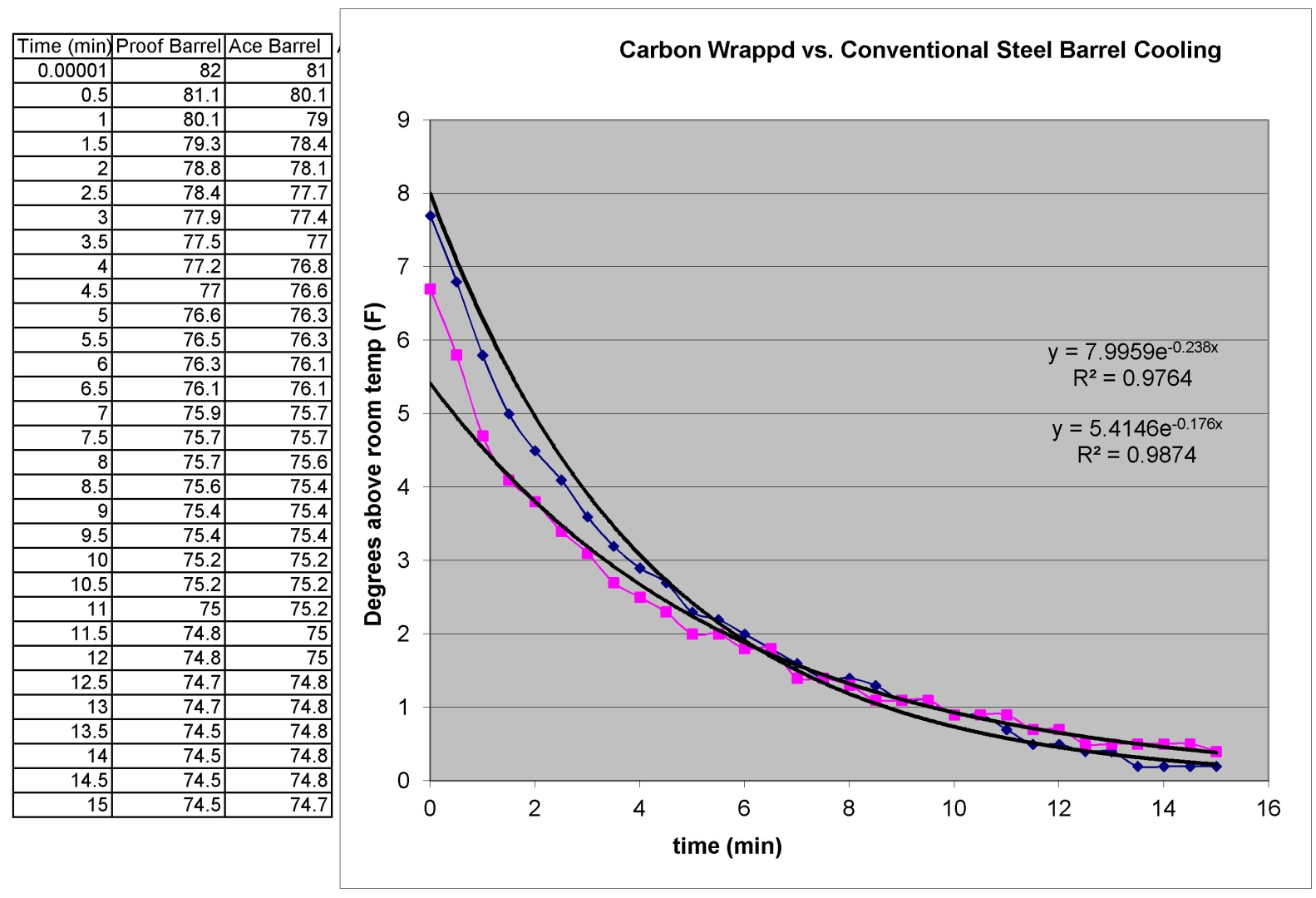

There has been a great deal of disagreement concerning how well carbon wrapped barrels cool. This is not surprising in that carbon fiber is highly directional in its conductivity, different makers differ substantially in how they lay up the carbon, and different resins also conduct differently. I set out to experimentally determine the comparative cooling rates of Proof’s carbon wrapped vs. steel barrels to answer all this concerning Proof’s products.

For this experiment I used two Vudoo V-22’s. One had a Proof carbon wrapped barrel and the other an identically contoured (Kukri) steel Ace barrel from Vudoo. The only other real difference was the steel barrel was 18″ and the carbon 20″. Given that the temperature was measured at the chamber for this experiment, I think the advantage to the carbon from the increased thermal mass and cooling area of the extra length is probably pretty small. Also of note, the ends of the Proof carbon barrel are Cerakoted as is the whole of the Ace barrel.

For the test, from room temp, each rifle was fed 50 rounds of ammo as fast as we could go. We had enough magazines to feed all 50 continuously. Immediately after this we pulled the bolt and inserted a temperature probe which was wrapped in painters’ tape to ensure that the probe would be the same depth in each rifle (.25″ past throat) and that the bore would be obstructed such that there would be no airflow through it. Time was started when the probe first ticked down instead of up in temperature. The temp it ticked down from was then recorded as the temp at time 0. After that, the temp was recorded every 30 seconds for 15min. Due to limitations in the software’s regression ability, the temperature in the room (74.3) was subtracted from the recorded temperature values before they were plotted and a line of best fit calculated. I should note here that the Ace barreled Vudoo had a misfeed during the final mag which slowed that mag dump and provided some inopportune cooling time. This may account for its not quite reaching as high a max temperature as the Proof, or that may be due to a difference in thermal mass between the two.

The cooling of an object is measured by Newton’s law of cooling:

T = (T0-S)ekt +S

T = temp

T0 = temp at time 0

e = Euler’s or “natural” constant (if you know what this is you probably understand this equation)

k = A constant related to the specific properties of the item cooling

t = time S = Initial temp

To make our software able to handle the regression, we utilized temp above room temp, making the equation: T-S = (T0-S)*ekt By doing our best to maximize how much of our heat transfer was via conduction as well as utilizing barrels of as close to the same dimensions as possible, we are essentially trying to get the “k” in our equation to be a pure measure of thermal conductivity. I expect we got pretty close.

As you can see from the equations of best fit on the graph, the k value for the Proof carbon wrapped barrel is -.2384 and the k value for the Ace conventional steel barrel is -.1761. This indicates that the Proof carbon wrapped barrel conducts heat about 35% better than the ACE 416 stainless steel barrel. This does not mean a Proof will always cool down 35% faster, as you will run into convection and radiation limitations to finally getting the heat out of the barrel which will be similar on both barrels. What it does mean is that the Proof can be expected have a pretty significant advantage in cooling speed.

Carbon Fiber Barrel Harmonics:

We all know that barrels vibrate while the bullet is on its way down them. The concept of tuning a barrel is the idea that by changing aspects of the barrel or ammunition you can change how much the crown of the barrel is moving at the time the projectile leaves it and that this is repeatable. Achieving a state of minimal crown movement at bullet departure will result in more precision from the precision rifle system. If you want to go further down the rabbit hole on theory and practice regarding this read my article on barrel tuning factory ammo. There is a claim that carbon fiber barrels are harmonically superior to steel, and I suppose this makes sense given that steel is used to make tuning forks and carbon fiber certainly isn’t. I had never seen any data on this but having heard it was probably why the idea started kicking around in my head when my Proof barreled Mesa Precision Arms rifle started to do unusual things during my testing of it with factory ammo.

The strange thing that the Mesa did is that it shot a lot of different factory match ammunition similarly well. Out of twenty-five shot groups from five different loaded ammunitions, 9 / 20 groups were between .4″ and .7″. Since one of the five produced no groups anywhere near that good, the other four ammunitions combined to have 9 / 16 groups in that small range and furthermore had only .108″ difference between each selection’s average group size. See the Mesa Precision Arms rifle review if you desire to see these target scans. All these ammunitions featured different bullets going at substantially different velocities, but they performed quite similarly. In my experience, this is unusual.

That experience got me thinking that if the harmonics of a carbon fiber barrel are substantially better than a steel one, as is claimed by Proof, it would be expected to show less variation between ammunition that is in tune and that which is not. This might show up as a lot of different factory ammo performing similarly, such as I had just seen. I would also expect it would show up in powder charge stepping load development targets. These would be expected to show less variation in performance between different charge weights. I would further expect, on a .22lr barrel, different lots of the same ammo type would performe more similarly. Since rimfire is not an advisable thing to reload, it would be an even bigger advantage on rimfire to have a barrel that is tolerant of more ammo. Furthermore, with rimfire barrel life being what it is, the cost increase over steel is also less dramatic. Given Proof’s pricing on carbon fiber drop-in rimfire stuff, the cost increase isn’t even that much. A Proof carbon drop-in runs about $650, depending on the rifle platform. You can see now where I was going with my thinking on further carbon fiber barrel harmonic testing. Time to do some load development on the 6.5CM and get a .22lr barrel for lot testing.

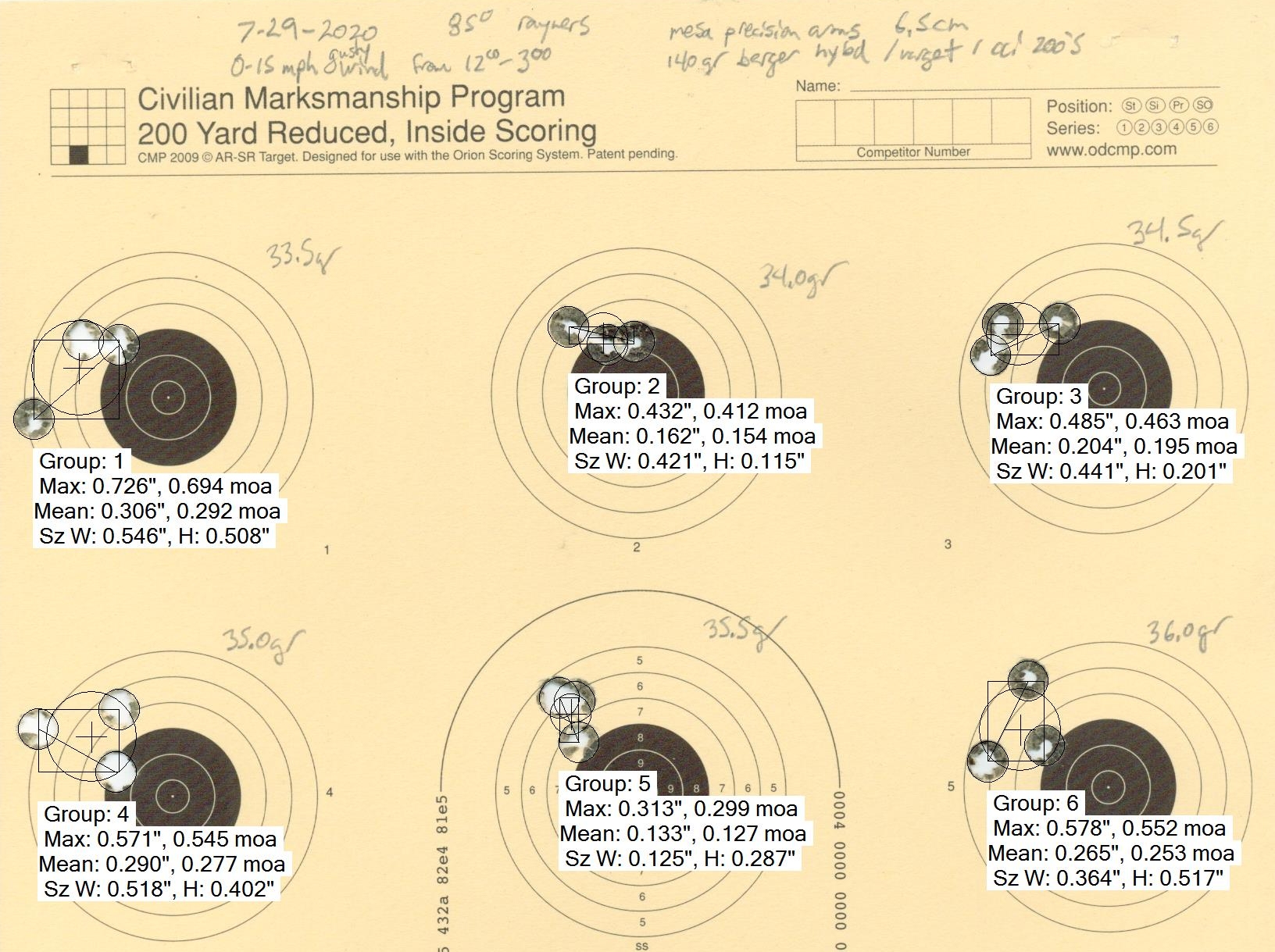

Having been sold on the RCBS Matchmaster dies while doing a review of them I purchased a set in 6.5CM and ordered some Berger 140gr hybrids. I loaded them to the same length as they were loaded in the Berger factory boxed stuff because why mess with a jump that’s working? I had plenty of Varget powder so I went with that, even though it is only so-so for 6.5CM and certainly won’t get 140s cooking at 2810fps while somehow barely kicking as the Berger loaded ammo did. I’m not sure how they did all that but bravo. The powder charge stepping load development target that resulted below is not a reloading suggestion. In fact, I think two of the charge weights are over the recommended pressures from the book I used. They are not over pressure in my particular gun but they might be for yours. Work up slowly, watch for pressure signs, and read your reloading manual for best practices. This is not a reloading tutorial.

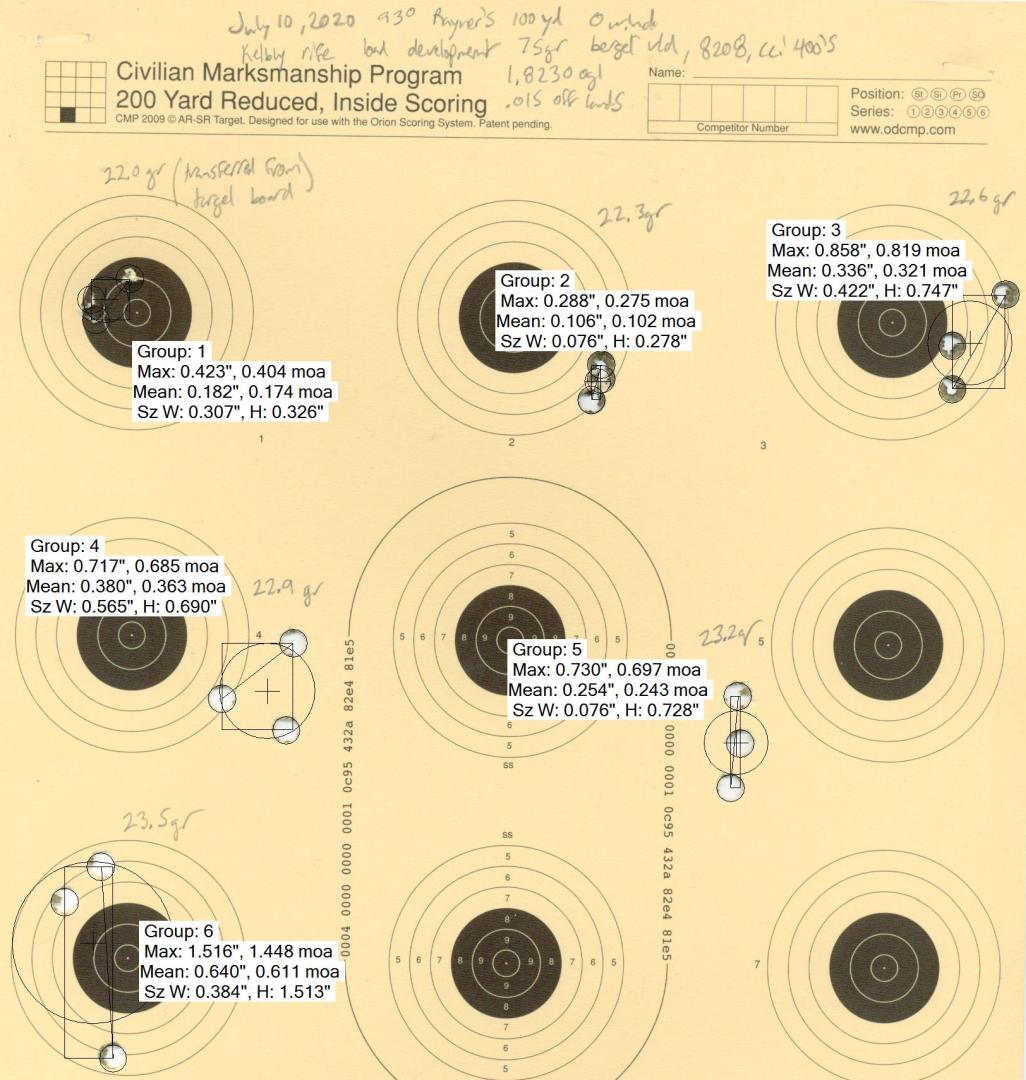

Well, aside from the first shot of the day going a little outside on the 33.5gr group, all these groups look pretty darn close to the same don’t they? No noticeable POI shift and not much variation in group size. They look like they were all the same ammo and not six different charge weights on a load development target. This is not what I am used to seeing on a load development target. What I am used to seeing is more like this (also not recommended charge weights) load development target from my.223 (Note: I changed POA between 22.0 and 22.3gr groups and between 23.2 and 23.5gr groups. The POI is shifting some with different charge weights, but not two inches.):

What you see on the Kelbly target is an above average example, but it is normal to see big group size difference between some charge weights and others as well as a noticeable POI shift. If things go well in a test like this, you get a group or two that look like they are on a good harmonic node such as the 22.0 and 22.3gr groups on this target and you load up some more of those to verify the node. The 6.5CM groups from the Proof barrel are unusual, being similar size groups with no POI shift while also being good groups. They look almost like harmonics isn’t a thing at all.

Well, I came off that test feeling good about this carbon fiber harmonics thing and thinking I might be on to something even bigger than I thought. Certainly, one barrel isn’t a pattern, however, so I sought out another. For the .22lr testing I wanted a solid platform to test the barrel in and an experienced smith I trusted to set it up. Drop-ins on factory rifles can often run into the issue that the factory rifles they are to drop into are not in spec, resulting in sub-par performance or outright problems. I also needed a test platform that would be similarly set up to other rifles with steel barrels for me to test against. Sending it to Vudoo solved all these problems as they do a great job and the Lapua test center just up the road from me is regularly lot testing for steel barreled Vudoo’s.

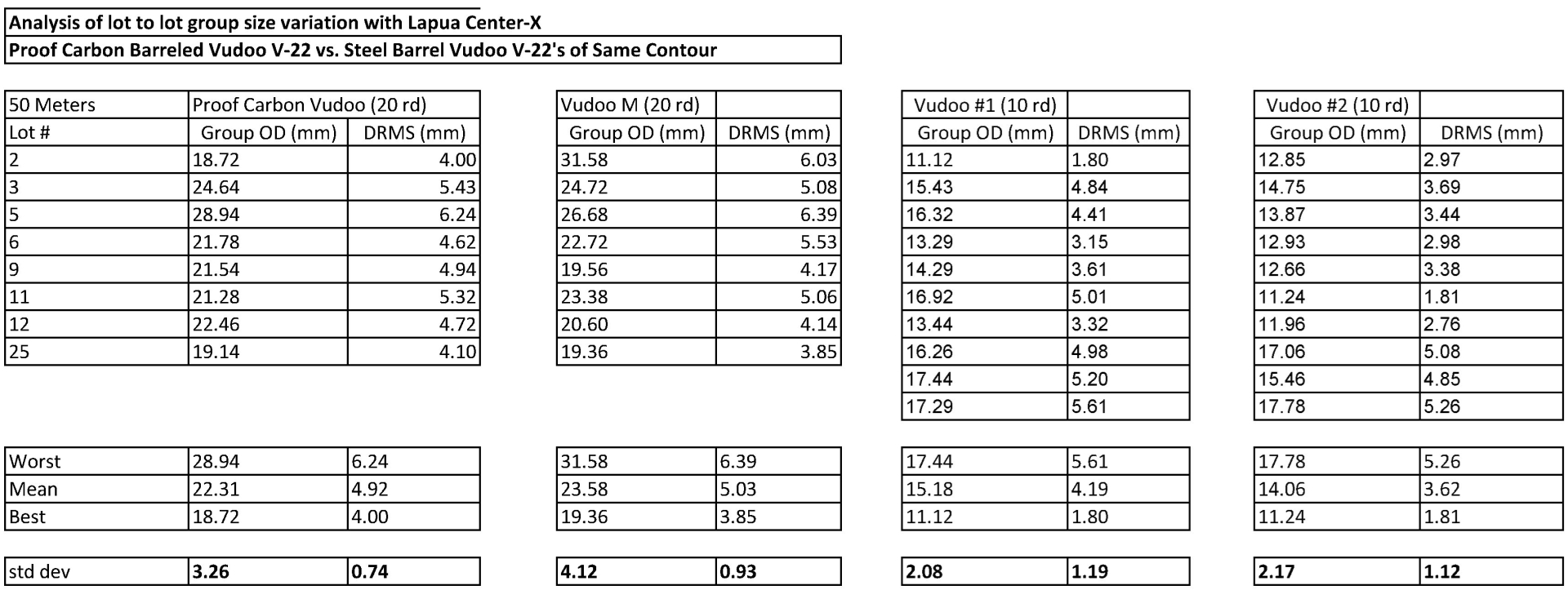

The table below has the outside diameter and DRMS (distance root mean square, a measure of the predicted diameter of a circle containing the center point of 63% of all shots fired) for each of the groups fired from my Proof carbon fiber barreled Vudoo, as well as three other Vudoos with steel barrels of the same contour. Lots are the same for the Proof Vudoo and Vudoo M and these groups are 20 rds. Vudoo 1 and 2 have the same lots as each other but are all different than those used with the Proof and Vudoo M, as they were shot earlier and the test center has changed out all lots since then. Vudoo 1 and 2’s groups are 10 rds each. The table also contains worst, mean, and best group statistics and, most importantly, the standard deviation of group OD and group DRMS. Those are the numbers we are most concerned with here because that tells us how much variation there is in group sizes between different lots. A barrel that has harmonic advantages would be expected to show less variation in group size from lot to lot. This will show up as a lower standard deviation of group OD and DRMS.

I do not find the data here decisive. The Proof barreled V-22 has the lowest standard deviation in DRMS of any of the tested barrels but does not have the lowest variation in group outside diameter. It does have lower numbers than Vudoo M which was shot in the same conditions, but change literally one crazy flier in lot 2 for the Vudoo M and that would disappear. Lot 2 looks the worst by far in the table for that rifle, but erase that one shot out of twenty and it is narrowly the best. Things are further complicated by Vudoos 1 and 2 having different lots, less rounds per group, and ten lots instead of eight. Standard deviations are not necessarily affected by a larger sample size, and once a sample size is large enough, even doubling it should have no directional effect. However, at low sample numbers the trend is definitely toward a higher standard deviation with each new sample and, mathematically speaking, these are low sample sizes. I could further complicate things by adding in the four more Ace steel barreled Vudoos I have lot selection data for. These rifles have larger group sizes (20-30rds) for ammo that started off testing well and smaller group sizes (3-10rds) for ammo that didn’t. That arrangement clearly results in decreased group-to-group size and DRMS variation so I didn’t use their data, but two of the four did show less lot-to-lot DRMS variation than the Proof. All in all, the data from the substantial number of .22 rifles used here does not conclusively support the idea the Proof has substantial harmonic advantages or disadvantages relative to conventional steel barrels. I think if you took the names off the data sheets and looked at them blindly you would not find any reason to determine that any one is particularly different than the others.

I think that the big split in the data here between the 6.5CM and the .22lr lot testing may be due to the tremendous energy difference between 6.5CM and .22lr. If you watch the slow motion of a centerfire rifle firing, the barrel whipping during the shot is clearly visible and dramatic. It is a tremendous amount of energy. Not so the .22lr. I think it is likely that a substantial degree of disturbance is necessary for whatever harmonic advantage a carbon barrel possesses to manifest. It is also clear to me now why I have found no quantification to the claim that Proof’s carbon fiber barrels have harmonic advantages over steel. I still believe this to be the case, but my impressions of this are stronger than the data and I suspect that may be the situation others who have made those claims find themselves in as well.

Summary and Conclusion:

It seems that after many years of research and development and trial and error Proof has found solutions to the substantial challenges of marrying carbon fiber and steel in a rifle barrel. Mine have shown no tendency to walk as they heat up and I have been hearing the same from others I trust. They also appear to have solved the larger issue of carbon / steel delamination. The cooling is worked out so well that not only is the carbon not insulating, but their barrels are 35% more conductive than steel contoured to the same specifications, according to my testing.

My testing of harmonics was less conclusive. My centerfire 6.5CM Proof carbon barrel is the most tolerant of different match quality factory ammunition that I have encountered. It seems to want to shoot groups in the .5’s with just about everything. Furthermore, load development with that barrel seems like a matter of just finding a good OAL and picking a speed that is not overpressure and strikes my fancy. The .22lr on the other hand did not seem to show any harmonic advantages or disadvantages relative to steel. I think there is something to the idea of Proof carbon barrels having harmonic advantages, at least in centerfire, but I did not find the ironclad data I was looking for.

Of course, the principal advantage of Proof’s carbon fiber barrels is their light weight. Proof claims up to 65% lighter weight than steel of the same contour. This is quite substantial. While this initially appealed to hunters looking to cut weight and carry a rifle without the issues that plague pencil barrels, the advantage has recently been migrating into competition rifles where it allows competitors to shoot substantially thicker, stiffer barrels and still make weight. This is a testament not just to the effectiveness of Proof’s carbon technology, but also to the quality of their barrel making, as competitive shooters require barrels made to the highest standards. Indeed, I have found both the 6.5CM barrel I have tested and the .22lr barrel to be lacking nothing in accuracy when compared to the match grade steel barrels I have used.

After spending the time I have now spent with Proof carbon barrels, I am not surprised they have exploded in popularity. This technology offers a substantial advantage in weight (or stiffness at a particular weight), cooling, and, I believe, harmonics. They do all this while delivering top tier accuracy and looking amazing. Proof has solved substantial technical challenges inherent in this technology leaving cost as the only downside.