Table of Contents:

1) Introduction

2) Grayboe Stock Technology

3) Geometry

4) Appearance, Fit, and Finish

5) About Bedding

6) At the Range

7) Summary and Conclusion

Introduction:

A bit over two years ago I reviewed the then new Grayboe Ridgeback stock. That stock was their first to include an adjustable cheek piece and aluminum M-LOK rails. It was also the first to be based on a geometry unique to Grayboe instead of one that originated with McMillan Fiberglass Stocks where Ryan McMillan, the owner of Grayboe, formally worked. At that time, Ryan mentioned to me that one of the directions they were looking to go in future models was an ultralight stock. This year that came to pass and at two pounds flat with an adjustable cheek and M-LOK system, the Phoenix looked interesting to me, so I asked to take a look at one and write a review.

Grayboe Stock Technology:

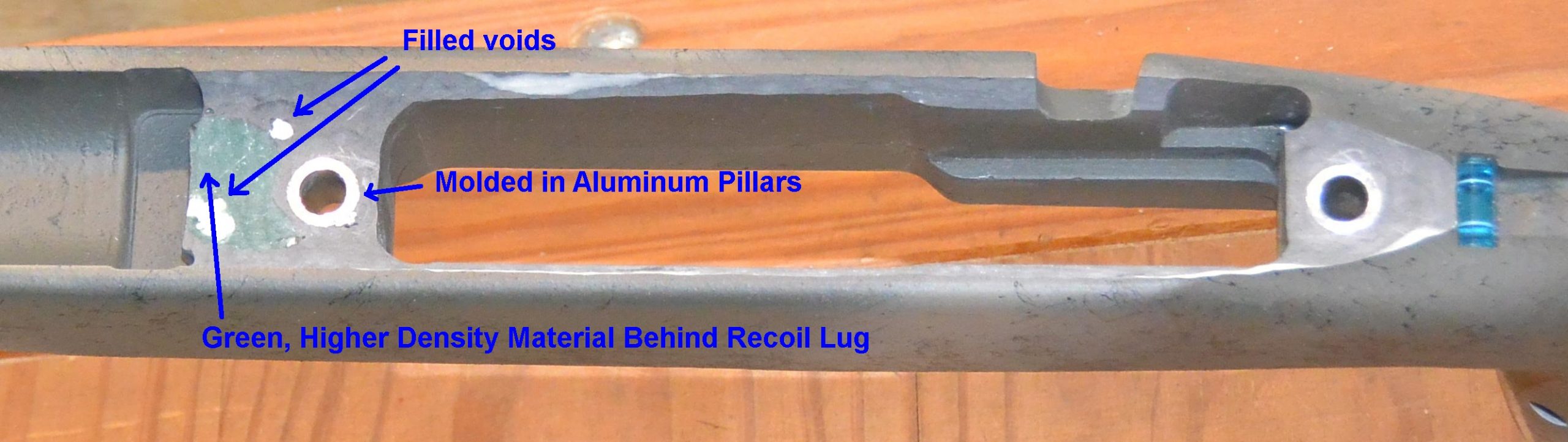

A Grayboe stock is a composite stock and it includes most of the same materials as other composite stocks: fibers (e.g. carbon or fiberglass), epoxy resin, and lightening additives. It is not, however, manufactured using the hand lay-up method like most other composite stocks. That method involves impregnating fiber fabric with epoxy resin and laying it in a mold to form a shell which you later fill with a less dense fill material and, finally, machine to inlet. All this takes a minimum of 8 man hours per stock and is typically more like 12-14 hours total. The Grayboe material is epoxy based and includes fiberglass fibers and lightening agents similar to a traditional composite stock. The manufacture process, however, produces a non-directional uniform material. My initial suspicions were that this was through the use of an epoxy injection molding process similar to those used for things like transformer housings in the electronics industry. After grinding a bit on it during the bedding process, however, I now suspect this is not the case, and that the molding process is low pressure. Both small air voids and places that appeared to have previously been voids but were filled in were present in the Phoenix just as in the Ridgeback I previously reviewed.

Grayboe developed its specific material formulations over several years and tests them at the composites center at USC. Their material provides excellent strength, stiffness, recoil absorption, and harmonics, just as a traditional composite stock does. Because of its non-directional nature, you also get more flexibility in where you can machine it for add-ons. During this review I ground, machined, and drilled the material extensively. I can attest that it machines very easily and with remarkable smoothness. Grinding out room for bedding compound or drilling for attachments is done with ease and also without worry of compromising the shell structurally or creating a starting point for de-lamination. All of the machining I did for bedding and for adding a molded grip took less than an hour. I do recommend a respirator or dust mask if you choose to do so, however, as the grindings have a good bit of fiberglass in them and are very abrasive. Using Dremel high speed cutters at 15k rpms is optimal for a smooth even cut. I should also note that the paint used is very tough and did not chip out at the edge of any of my cuts or drills; this was very helpful in leaving a clean finish. Of course, cutting and grinding on the stock will void your warranty as well.

In my opinion, the biggest benefit of the Grayboe process is that, having eliminated the long labor hours of the hand lay-up process, Grayboe stocks can be made at significantly less cost. The Phoenix can be had with a quality DBM for $650 vs. around $1,000 that a comparable composite stock with DBM costs and, in addition, the Grayboe has a few more extras, such as a bubble level and M-Lok system. Grayboe stocks come with aluminum pillars molded in place. If you intend to bed your Grayboe, you simply machine around these and they provide proper spacing and support for your action during bedding.

The biggest difference I noted in the construction of the Phoenix vs. the Ridgeback after inletting the stock for bedding is that the Phoenix has some higher density green-colored material directly behind the recoil lug to provide greater strength for magnum cartridges. The stock material feels and looks the same on the Phoenix as it does on the Ridgeback, though I am told it is actually a little lighter and so the stock has been reinforced here. The Phoenix also has some areas hollowed out or otherwise thinned down, such as the inside of the grip, the barrel channel (which as a result will fit a 1.25″ straight taper), and the buttstock portion. Additionally, the Phoenix uses a smaller diameter guide rod for the cheek piece though it actually has more range of adjustment (1″ vs 3/4″).

Geometry:

I find myself in a unique position reviewing the Phoenix as I have both a Grayboe Ridgeback an adjustable McMillan Game Warden on hand. These are two stocks that most shoppers for the Phoenix will undoubtedly also look at as the Ridgeback is Grayboe’s other adjustable composite stock model and the Game Warden is probably the most popular lightweight composite hunting stock on the market. Below you will note the side by side comparison images of these stocks.

Superficially, the Phoenix closely resembles the Game Warden, It has no hook, a similar silhouette, and it is about the same width with just a slightly deeper untapered fore end. Side by side, they look quite similar in geometry. On the dimensions of greater importance to the human interface, though, the Phoenix is actually closer to its stable mate. For example, the drop from bore to comb is relatively small on the two Grayboe stocks (1/4″ on the Phoenix, 7/16″ on the Ridgeback) and higher, 3/4″ on the Game Warden. The distance from trigger pad to the front of the grip is also lower on the Grayboes, 1 3/4″ on both, and higher on the Game Warden at 2 1/8″. In other words, the Phoenix and Ridgeback are sized for slightly smaller features than the Game Warden. They are still sized for larger hands than I have, but maybe not quite Shaq size. When it comes to comb height, however, the Phoenix and McMillan can both go higher: the Phoenix starts higher and has 1″ of travel and the Game Warden starts lower but gives you a full 1 1/4″ of travel. The Ridgeback has only 3/4″ of travel and has left my high cheekbones a little short with some of the higher scope mounts I use. Between the extra adjustment height and the higher starting point, this is not a problem with the Phoenix. I measure the LOP range on both the Phoenix and Ridgeback at 12.5″ – 13.86″ with the five included spacers. The LOP on the Game Warden will be fixed at whatever you order, as it is a custom stock with no LOP adjustment.

How you feel about the fit and dimensions of a particular stock is greatly dependent on your body’s size and shape. One of the biggest fitment issues my body tends to have is high cheekbones and a preference for a higher, more vertical head position. This causes me to often have insufficient comb height. My hands are also on the smaller side of average, leading to poor grip fit. The Phoenix has enough max comb height for even my geometry and preferences, but as is usual, the grip is further from the trigger than fits me. As such, I added some inserts for a custom molded grip when I bedded the stock. This is quite easy to do on a Grayboe as the material is robust, uniform, and easy to machine. The grip section being hollow on the Phoenix did not complicate this, as it is still thick enough to support the whole insert.

Appearance, Fit, and Finish:

The oddest thing to me about the manufacture of Grayboe stocks is that some of the inletting of the action for trigger area and magazine box appears to be machined out, but the surface on which the action itself will rest is molded and not machined. This molding is not ideal particularly in the area directly behind the recoil lug that has been reinforced on the Phoenix with the green-colored material. On my stock and others I have seen, this area is uneven and poor in appearance. This was not the case on the Ridgeback. That stock appeared to have pretty even contact with the action out of the box as evidenced by where the action left smooth contact spots on the paint. On the Phoenix however, the contact did not look even so I wrapped the action in thin tracing paper and torqued it down for a few hours to illuminate the contact areas. As you can see below, the tang has reasonably distributed contact but the front of the action is really only riding on the front pillar. Whether this is ultimately a problem for accuracy or not I will discuss in the section on bedding, but I think it will at least bother people cosmetically so it is worth mentioning here as it is part of a pattern of small imperfections in non-visible areas of Grayboe stocks – such as paint overspray in the barrel channel and surface unevenness caused by painted over small pockmark voids – that people seem to talk about on the forums a lot. The visible parts of the stock, in contrast, are smooth and evenly painted with the quality of the paint being particularly good. The paint is durable, resistant to chipping out when being machined, and evidently can even be Cerakoted over for those individuals I have noticed who seem determined to Cerakote everything they own.

Notwithstanding the unevenness and low contact area of the action inletting, the pillars are properly spaced and aligned such that with the action against the recoil lug, the screw holes are properly centered in the pillars. Similarly, the bottom metal is properly aligned and spaced such that even my .22lr V-22 feeds perfectly from its plastic magazines. The aluminum Vudoo magazine is a little too large to fit in the Grayboe bottom metal so you will want to go with Vudoo bottom metal if you want to use those. Contrary to what most folks think, not all AI pattern magazines fit in all M5 type bottom metal. There is no one universally industry recognized spec on these things (though Mike Bush of Vudoo will tell you there is a spec and that many just don’t follow it). As a consequence, not all magazines end up fitting all bottom metals or chassis correctly.

The Phoenix is quite generous in what it will accept as far as actions go. The recoil lug area is large enough that I expect it will fit any 700 semi-clone and the sides do not extend as high as the ejection port so no additional inletting is required to accommodate longer ejection ports. When ordering directly from Grayboe you can also have your action or bottom metal inlet slightly altered to accommodate not quite 700 / M5 clone parts such as a Bergara bottom metal or an action with a trigger hanger like the the Kelbly Atlas.

About Bedding:

The official Grayboe stance on bedding is that they have not seen any noticeable difference in accuracy between bedding their stocks and using them unbedded. I have now bedded both a Ridgeback and Phoenix and have likewise observed no noticeable change. That being said, I didn’t fire a whole lot of groups before bedding so the difference would have had to have been a striking one in order for me to notice. I also only ran each stock one day before bedding and so could not have noticed zero shift between days, which some say can be bedding related.

Quite frankly, bedding is a generally tricky subject on which a lot of people often talk out their ass with little data to back it up. The gold standard, followed by benchrest guys and Accuracy International, is to permanently glue the stock to the action. Obviously, this limits your future options and makes servicing the rifle a bit trickier. Hence, benchrest 700 action makers use trigger hangers. Next on the list of reputable bedding techniques is glass pillar bedding such as I have done on this Grayboe stock. With this method, Aluminum pillars set the space between the action and bottom metal and a glass reinforced epoxy mix of one or another Voodoo concoctions is used to create a precise mold of the action in the stock. On down the line of bedding variations, you have skim bedding, various epoxy glob variations where only parts of the action are bedded, full-length bedding, pressure bedding, and shim bedding. Even within the dominant glass pillar bedding strain of thinking, exactly what parts are bedded is disputed; some bedding the barrel a few inches in front of the recoil lug and others only bedding behind it. In short, how exactly to prevent the stock from putting differing strain on the barreled action at different times and therefore changing its behavior is not totally agreed upon. Even what precisely you’re going for is not agreed upon, since some think you are trying to minimize all strain on the action by giving it a large area of even contact while others happily shoot tiny groups with V-block based chassis where the contact area is small and far from the action screws, leading to plenty of strain on the action. What I am saying is that the glass pillar way of looking at stock-to-action interface appeals most to my thinking, but I have shot V-block chassis and bare ass wood stocked guns that were hummers as well as beautifully glass pillar bedded duds. More often than that, I have bedded rifles that must have been good enough and saw no noticeable change at all.

At the Range:

The Phoenix is light. My example weighed in at only 29.2oz with two spacers and the lighter hex head cheekpiece adjust screw. I believe this makes it the lightest adjustable composite hunting stock by about half a pound despite having a weight adding M-LOK rail system absent on most competitors. As such, one of my biggest curiosities was how it would feel under a decent amount of recoil. The new lightweight recoil pad they are using feels good and composites generally recoil softer at a given weight than a chassis, but who really knows until you try it. To facilitate this, I decided to party like it’s Y2K and break out the Remington 5R .308 that once dominated the SnipersHide forums. Really, the recoil felt about like I expected. The soft pad distributed the pressure well, preventing the rifle from feeling like it dug into you when it lurched, but it is nevertheless a very light package and gives you a solid thump. The Phoenix would not be my choice for regular 50 round+ range days with middle size to large calibers, but you will not feel a few rounds the day after hunting unless maybe you are running a lightweight 300 WSM without a break.

Also of interest to me was how the skeletonized buttstock would feel with rear bag in hand and how it would ride the bag. This is an area where I feel many chassis and even tactical style stocks leave me wanting. Often there is either little to interface with a bag or a geometry that makes it difficult to make small adjustments to the rifles angle by manipulating the rear bag, e.g. a hook-shaped stock with a large, high gap. Bipod leg adjustments are relatively course and slow and I like to be able to move my point of aim a good bit using just the rear bag. I also like to have some meat to the rear of the stock to squish the bag against, giving it some stability. Having an angle to the underside of the buttstock as is traditional in hunting stocks, the Phoenix adjusts well via the rear bag. It is better than I expected and good enough. The bottom line of the stock being thick instead of thin, as they could also have chosen to make it, is really the saving design decision.

Another thing I noticed when shooting the Phoenix was that, like the Ridgeback, it feels like a painted composite stock and not at all like a plastic one. I am not sure if this is a difference in the surface feel, stiffer flex, or how the weight balances, but composite stocks, whether hand lay-up or molded for a uniform non-directional material, feel substantially different than plastic ones. Grayboe’s unique and simple molded adjustable cheekpiece is solid on the Phoenix just as it was on the Ridgeback. It takes more force to lock down than a traditional pinch block and has no lateral adjust or cant, but it is solid, simple, inexpensive to manufacture, and also very light -an ideal solution for this lightweight model. It is also quick to remove, which is important as it starts high enough on the Phoenix to require removal for cleaning. Lastly, Grayboe’s switch to a dark blue bubble level from the original clear one with greenish-yellow fill gets a ‘boo’ from me. The new level is not visible to me in many lighting conditions in which I never had problems with the old one.

Summary and Conclusion:

I think it’s safe to say that Grayboe is going to sell a lot of these Phoenix stocks. They come out of the box quite well appointed with flush cups built in both sides, an M-LOK rail on the bottom, a 1″ travel adjustable cheek, a bubble level you can see in just the right lighting, and a spacer adjustable LOP. With all that stuff, they weigh only two pounds flat, and with a little shopping you can get one for $650 including Grayboe bottom metal – a substantially better price than the normal $600 with no metal. With sides that do not extend past the ejection port, a roomy recoil lug area, and a huge barrel channel, these will fit almost any semi-clone 700 out of the box, with the possible exception of a little grinding being necessary to fit an action with a trigger hanger. 700s and clones (including longs and the weird Defiance medium) are the only actions the Phoenix is currently available for, though other action inletting is slated. The Phoenix also currently only comes inletted for DBMs and not BDLs so you will have to enter this millennium and use a detachable magazine, at least for the moment.

For this review, I went with the Woodland Camo painted finish. This is one of the standard cost finishes on the Phoenix. I found the finished appearance of all visible parts of the stock to be excellent and the paint durable. On the non-visible portions of the stock, such as in the barrel channel and inletting, the appearance was less finished, with small voids in the molding visible as well as less even paint texture. I have noticed this bothers some folks on the forums for some reason. Perhaps more relevantly, I found the action did not have even contact with the stock throughout the inletting for it. The section of the action in front of the magazine cut really just rests on the aluminum pillar with a little more even contact under the rear tang. In my short testing prior to bedding, I did not find that this adversely affected accuracy, but I think it will bother some users and I would have chosen to bed it for this reason had I not been bedding it anyway as part of the review process. Machining and drilling Grayboe’s non-directional material for bedding and the placement of inserts is smooth and easy. Due to the ease of doing so, modifying Grayboe stocks is quite popular despite the fact that doing so voids the warranty. The positioning of the pillars on the Phoenix was excellent with the action screws nicely lining up in the center of the holes when the action was properly in place. The alignment and spacing also provided for good magazine feeding, even with a .22lr Vudoo action in it despite the small margin for error that such a small cartridge has. The Grayboe bottom metal notably was too snug to fit the aluminum Vudoo magazine, though it fit the plastic ones I prefer quite well. So if you are doing a Vudoo and want the big 15rd aluminum magazines, I would suggest going with Vudoo bottom metal.

Shooting the Phoenix, I found its geometry comfortable, its feel stiff and robust, and its recoil absorption good enough to hunt with anything I would be willing to use in any other two pound stock. I felt the .308 while I was shooting it but not the day after. The high starting comb height and full 1″ adjust range should fit most users, even with the surging popularity of more vertical head positions, and many will find the grip positioning to work though, as usual, my hands are a little small for the geometry.

I think Grayboe has a winner on their hands with the Phoenix. The hunting market is large and cares about both cost and weight a lot more than the tactical market. This has often led hunters to sacrifice stock adjustability for themselves or proper action support for the rifle. The Phoenix has the user adjustability and proper action support to be a precision rifle stock and I’m sure some will use it for that. It brings this at a hunting weight and at least a hunting adjacent cost. When all these different aspects are considered together, I am not sure the Phoenix has any direct competitors – not a common occurrence in the saturated 700 accessory market.