BigJimFish

Dec 17, 2024

Table of Contents:

Introduction

Note on the Straight Wall Precision Project

SKLTN Action Features

Titanium vs Stainless Steel Discussion

Fit, Finish and Field Notes

Altitude Composite Stock and Bedding

Hawkins Hunter Bottom Metal, Magazines, Proof Barrel, and XTSP Trigger

Accuracy Testing

Summary and Conclusion

Introduction

I first met the guys behind PurePrecison back in 2018 when I did a review of their Crux Titanium action and rifle build. That rifle hammered then and continues to do so now. I call it my omnivorous rifle because it loves whatever you feed it. When I reviewed the Crux, John and Chad were just setting out on their own after their respective service in the Marines and subsequent employment in the outdoor industry at Red Hawk Rifles and U.S. Optics. At that time, they were basically running a small custom rifle building company that also did some sales of actions that they speced out from an action manufacturer. These included the Crux.

Since that time, PurePrecison has grown their manufacturing by taking on partners from an aerospace machine shop they had previously worked with so that they now manufacture actions in-house. The SKLTN we will be looking at in this review is the first such in-house manufactured action model from PurePrecision. While still including the custom rifle shop function that produced the Crux rifle a few years back, PurePrecison has also added a large retail function they are calling The Battalion that sells a variety of high-end optics, reloading components, ammunition, shooting accessories, and rifle build components from both PurePrecison and other makers. Their in-house manufactured actions we are looking at here are intended for their custom rifle business, to supply other smiths for custom rifle builds, and for use in the increasingly popular DIY pre-fit market. Pre-fits are available from Carbon Six, Helix 6, Precision Rifle Blanks, Straight Jacket, McGowen Precison Barrels, and Proof Research. As such, the Proof barrel utilized in this review is a pre-fit and was pre-chambered to spec by Proof instead of being chambered, threaded, and crowned by the PurePrecision guys.

Note on the Straight Wall Precision Project

When PurePrecison approached me last October about doing a review of the SKLTN, their new in-house manufactured lightweight skeletonized 700 platform action, my immediate thought was that this was a good fit for the Midwestern straight-walled deer hunting rifle experiment I had been kicking around in the back of my head for a couple years. The idea of this project is essentially to examine the potential of hunting with these straight-walled cartridges at distances where rangefinding and drop compensation is necessary. In states where slug shotguns were the rule just a few years ago, this has tremendous potential and I wanted to, and will be, examining this in some depth in an upcoming article on the precison straight-walled cartridge rifle. For a number of reasons, 350 Legend appeared to be the best cartridge for the project and so that is what I proposed to the PurePrecision guys.

I know that being from Colorado, this request came out of left field for PurePrecision and it would not have been their first choice. At that time, few had even tested to be sure 350L would likely feed from some AICS .223 magazines and, for a number of reasons that will be discussed in the upcoming article, 350L does not have a good reputation for accuracy. Worse still, this caliber choice would delay the timeline a bit as the standard (.308 Win etc.) and magnum (300 WM etc.) bolt faces were completed but the smaller (.223 Rem etc.) bolt face was not yet finished. The project seemed interesting to them but the potential for problems was high. Still, they were willing to give the unusual project a try despite the risks.

My observant reader will, by this point, have noted from the dates mentioned that this review ran a year from inception to completion and therefore not every element of the 350L project went quickly and smoothly. That is indeed the case and the SKLTN action review has borne the brunt of this in delays, despite the action causing none of those problems. In fact, the action even weathered some inadvertent over pressure testing from some faulty ammo that was recalled and the action did not suffer any damage as a result. I have learned a tremendous amount about the 350L cartridge specifically and straight walls in general during this time that will result in a number of useful articles and videos. Hopefully this provides compensation in terms of exposure for the long delay in publication resulting in my unusual caliber choice. Big thanks to PurePrecision, Proof Research, Hawkins, Hornady, XTSP, and Barnes for facilitating this research. I believe many will benefit from it.

SKLTN Action Features

As I am sure you guessed from the name, the SKLTN is a lightweight skeletonized action. At 16oz for the titanium version and 21oz for the stainless, I believe it is actually the lightest 700 footprint action available. PurePrecision has been more creative than most to facilitate this, including hollowing out the front of the integral recoil lug, fluting the firing pin, and removing some material on the flange of the one-piece bolt. This skeletonization, combined with the integral recoil lug, has been so effective at reducing weight that the Stainless version of the SKLTN action I am looking at in this review is the same weight as the Crux Titanium I previously reviewed. As with that previous action, the SKLTN features toolless bayonet style bolt assembly and disassembly, a two-lug bolt with 75 degree throw, an M16 style extractor with plunger ejector, and a side bolt stop. Updated for the SKLTN are the overpressure relief vent hole, an integral recoil lug, and one-piece bolt design. Like the Crux, the SKTLN is a lathe turned action and can have an optics rail attached with large screws and pins or can accept Nesika Bay style rings for even lighter weight and a more hunting rifle look. The SKLTN can be used with AICS magazines or with Wyatt’s extended internal box magazines. The stainless SKLTN is made of 416 stainless and the titanium version is grade 5 TI-6AL-4V titanium. By default, the Titanium action comes with a black PVD coating for better lubricity, whereas the stainless one is uncoated. Black PVD can be added to the stainless at the customer’s request for $80. They can also have Cerakote done for less if you’re just looking for the color. The bolts for both the stainless and titanium versions have a black nitride coating. These bolts have a deep spiral fluting on the bolt that is done in two stages for both lighter weight and removal of the sharp edges that result from single-stage deep fluting. The effect is excellent: the bolt does not scratch up the cartridge case as those with sharper deep fluting often do, but aggressive weight removal remains. In addition to stainless and titanium options, you can also choose short or long action as well as standard, magnum, or the .223 rem size bolt face I have on this example.

Titanium vs Stainless Steel Discussion

Whether it be guns, golf clubs, race cars, springs, or orthopedic implants, titanium and steel are often suggested as alternative material choices for the application involved. The strength, flexibility, corrosion resistance (in the case of stainless), and lack of toxicity can be quite similar, depending on the alloys involved, between these two elements. In the case of this action, the alloy we will be speaking of is Grade 5 Ti-6AL-4V titanium.

Comparing this alloy with the variety of steel alloys used in actions will yield a few general trends. The first and most obvious trend is that the titanium (“Ti”) is about 40% lighter per volume. It is a common misconception that titanium is also stronger. By weight this is certainly the case, but by volume, the comparable steels will be a little stronger. Both materials have good flexibility properties in that they flex and return to original size without fatigue or strain hardening over a fairly large range. This is why Ti and steel alloys are the most common spring materials in industry. The titanium flexes more easily however, and this does mean that in a Ti rifle your brass casings will flex many times more, wear quicker, and could cause harder bold lift in high pressure loads. While stainless, as its name implies, does have corrosion resistance, it has nothing on Ti, which is basically immune to corrosion at normal atmospheric temperatures even in the presence of salt. Ti can be made fairly hard at about 36 Rockwell C, but steel is commonly harder than that and this hardness, combined with less of a tendency to gall, makes steel actions feel smoother and want for less lubrication than Ti. Despite Ti’s corrosion resistance, titanium actions do not run well dry.

The dominance that steel enjoys over titanium in terms of prevalence does not result from hardness and strength advantages. This dominance has far more to do with costs of the raw material and, to the greatest extent, costs and expertise to machine. In cost of raw material, titanium is somewhere around twice the cost of steel for similar quality stuff, but in terms of machining, it is often said to be about five times more costly, once slower feed speeds, greater tool wear, and various other things like the chance of its little shavings catching fire are considered.

The sum of all this comparison is that you are probably not going to use titanium for the PRS rifle which you are going to go through barrels and brass like water with, but if you are looking to make a lightweight hunting rifle, a titanium action saves 5 oz for the cost of $400 in the case of a SKLTN short action.

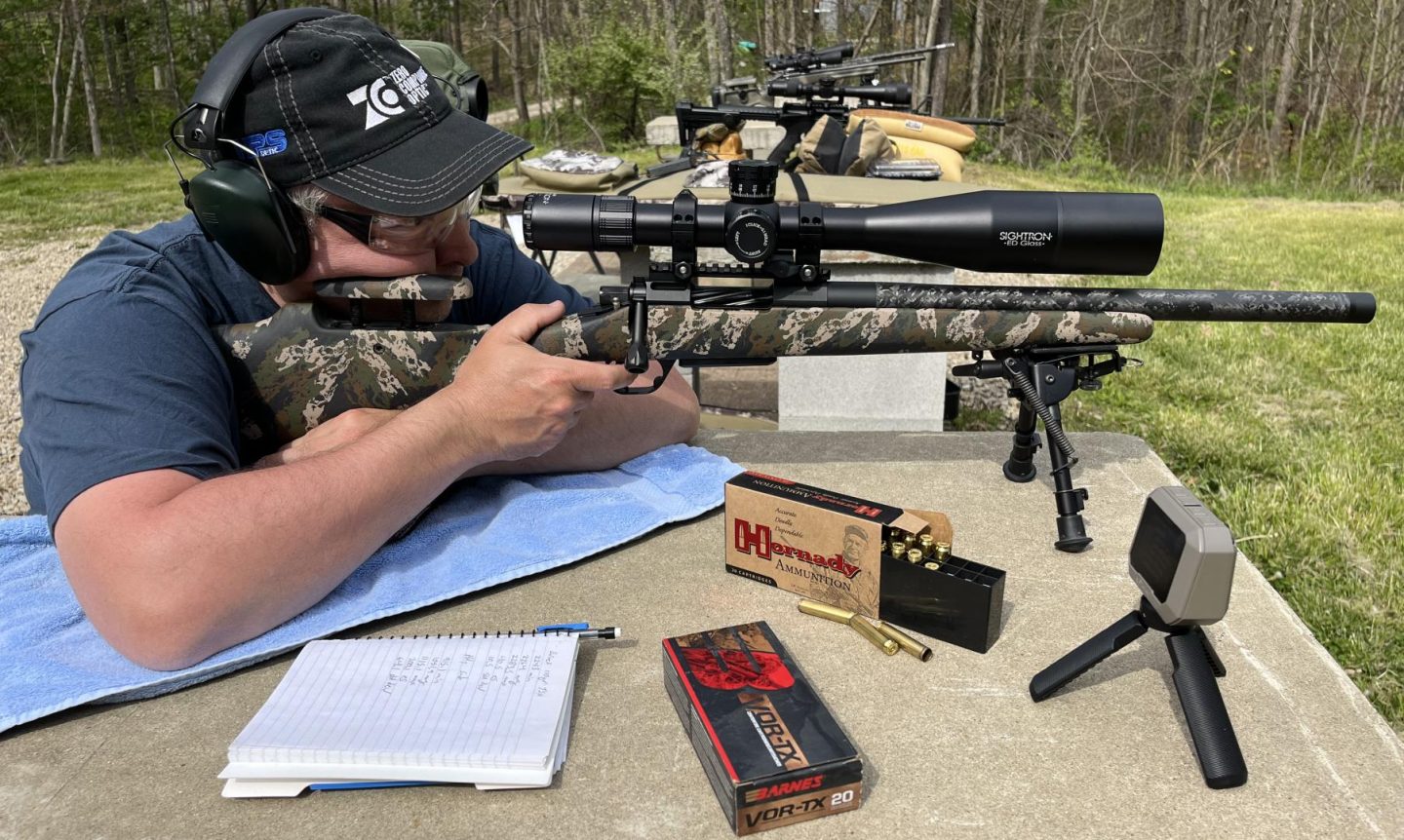

Fit, Finish, and Field Notes

It is interesting to see the evolution of the thinking of the PurePrecision guys between the Crux action and this SKLTN action. The unique 75 degree bolt throw and toolless bayonet style disassembly remain, as well as the basic design choices such as being two-lug with push feed, M16 extract, plunger eject, and pinned trigger, but a number of other aspects have been updated. First off, PurePrecision has switched from a two-piece bolt to a superior one-piece design that will be more precise, more robust, and with a lower cost to manufacture. They have also switched to an integral lug on the action and ditched the beautiful (but suboptimal) hexagonal bolt fluting in favor of a more common helical style. Their choice to run a second radius on the fluting is a big win. It is far less sharp and this is noticeable in how smoothly the action runs. The SKLTN action I have here is stainless but has been Cerakoted. Like other Cerakoted actions, the bolt movement was a little sticky to start with but it is well worn in now and feels great. Also feeling good is the bolt lift which, despite being only a 75-degree throw does not feel noticeably heavier than the various 90-degree actions I have lying about. That is a big win as cocking force is a common complaint on actions with less than a 90-degree throw.

The biggest update on the SKLTN action is, of course, the weight relieving machining on a number of the components. PurePrecison has been quite thorough in their search for places to machine off weight. The bolt handle is hollow. The integral recoil lug has been relieved. A number of bevels and pockets have been machined all over the action body, even underneath were the trigger attaches. They slimmed down the cocking piece shroud and fluted the firing pin to go with the fluted bolt. A few tiny little pockets have even been machined on the bolt behind where the handle attaches. On the bolt alone, the machining and slimmer shroud combined are enough to drop two ounces from 11.3 to 9.3 from the bolt present in the Crux rifle. That is an 18% weight reduction in an otherwise similar part. That is huge difference. All of the machining on the SKLTN looks absolutely excellent. The fit and finish is top notch and it has drawn appreciative comments on nearly every trip to the range.

A few other notes from my use are that I very much appreciate the lighter ejector spring on the SKLTN relative to most other push feeds I have used. The brass from the SKLTN does not bombard the shooter in the next lane over and send you on a scavenger hunt if you want to collect it. Another simple design element on the SKLTN that has offered an outsized quality of life improvement is that there are flats machined in the action where the trigger connects. These offer purchase to keep the action from spinning when a trigger is added or removed. They are super beneficial. One note though: if you Cerakote an action with a pin-mounted trigger, be sure to either plug the holes when you coat it or scrape off the coating before hammering in the trigger pins. They were a bear to remove that first time. Lastly, PurePrecison has done a great job with the attachment of the optics rail. It is secured with big, honking robust machine screws as well as pins. In general, I am a fan of lathe turned actions such as this SKLTN. They are a lot cheaper than one-piece machined alternatives and offer more choice to the user in rail angle. Lathe turned actions are also much rounder and I believe this provides better average performance than one-piece actions have when used un-bedded in chassis systems or in stocks that do not require bedding. With this robust rail attachment mechanism, I believe PurePrecison has done a good job shoring up the largest potential downside of this construction.

Altitude Composite Stock and Bedding

PurePrecision’s Altitude stocks are line of hand lay up carbon fiber composite stocks offered by PurePrecision both through their custom shop and though their Battalion web store. These are a design manufactured for PurePrecision by a third-party supplier and not manufactured in-house. The construction of these stocks is traditional hand lay up with carbon fiber shells, lightweight machineable fill, and aluminum pillars. These stocks can be purchased as part of a custom build through PurePrecision or ordered ready to bed and build yourself. In both cases, the stock is a custom part. Barrel contour, color, action inlet, bottom metal inlet, and attachments such as flush cups and ARCA or Pic rails can all be specified. As it turned out, my particular stock proved to be a little too much of a custom part, as it arrived at my door without the ARCA rail or flush cups which I asked to be installed. I doubt this will be your experience, as you will most likely be using the normal order form instead of requiring the coordination of a bunch of different parts arriving from different suppliers at different times through e-mails and texts with several different people for an action that wasn’t yet even in the catalog at that time. However, I would be remiss if I did not note the mix-up.

The main benefits of a composite stock are its temperature and moisture stability, rigidity, relatively low weight, recoil absorption, harmonic dampening, beauty, and comfortable rounded shape. This combination of factors has kept composite stocks the top choice for most high-end hunting builds. They have likewise remained my most common choice for rifle builds. I like both the rounded, not too hot, not too cold feel they have when compared to a metal chassis, and I feel they offer a less jarring recoil experience as well.

The particular model I have here is the Remington / Clone Adjustable Altitude. In most respect its geometry is very traditional for an American hunting rifle. Its departures from that size and shape are a slightly widened forend to accommodate larger barrel diameters, a more vertical grip angle, and an adjustable comb. This adjustable comb has a pretty large 1.25” or so of vertical range and is adjustable for more than just height as well. The comb can be moved right or left around .25” each way or angled in the horizontal plane using the same mechanism. This adjustability is not immediately obvious, as it is done by loosening the vertical rods using the hex heads you may be surprised to find they have on their bottom. It’s a pretty clever mechanism. The same size hex key is also used to raise or lower the comb. No thumb wheel toolless alternative fastener is included. The finish of the Altitude stock is a nice looking sponge camo paint job over some sort of matte undercoating that provides a bit more grip when wet than shiny bare resin. The stock also has molded-in texturing on both the grip and forearm. All in all, it’s a nice comfortable stock and it’s priced at the entry point for a traditional hand lay up composite stock.

Instead of building and bedding the rifle myself, I had PurePrecision do this. Unfortunately, the bedding and bottom metal fitment were not great. They were not done to the standard of the bedding job PurePrecision did on the Crux a few years ago. The bedding job on the Crux extended an inch or so under the barrel and was continuous to the tang. The fit of the barreled action and bottom metal as well as the bedding job were perfect. Exactly what you would expect from a custom rifle builder. The SKLTN rifle uses a two point bedding technique with tape creating space between the barrel and the bedding compound forward of the lug. There is nothing wrong with this bedding technique vs. the continuous one used on the Crux. Different philosophies exist on this point and competitions are won with both. I’m just noting the change here. What is incorrect is that there was bolt handle / stock interference such that the bolt handle came to rest on the stock instead of the notch in the action where it was supposed to rest. The bottom metal was also impacting the stock fill at a central point, causing it to deflect and for stress to be added to the system as the action screws were tightened. The barrel is very slightly angled left in the barrel channel. This is purely cosmetic, the barrel is still properly free-floated and the angle is slight enough it might go unnoticed by many, but I did notice it. Lastly, the back of the bottom metal is sitting about 1/16th of an inch below stock surface, causing the lip on the Hawkins hunter magazine to impact the stock and not fully seat. This is not an acceptable fitment and bedding job to be leaving a custom rifle builder, and training and QC needs to be improved to prevent this. This is always a difficult point as a custom shop expands beyond its founders and new employees come on board.

Hawkins Hunter Bottom Metal, Magazines, Proof Barrel, and XTSP Trigger

Once a rifle build starts as a platform for a review project, it often serves as an opportunity to try out other new components and, depending on the component involved, this often leads either to a full review of that component or a mention of in the review of the primary component.

The first of such products on this project is the XTSP Mod 22 trigger. I had wanted to try this trigger out for some time, as the design is actually one of the earliest two-stage triggers for the Remington 700 platform. Variants have even been used in a couple U.S. Military sniper rifle over the years. Being as XTSP is located in Ohio and the 350 Legend cartridge this rifle is chambered in is most popular in that state, this seemed like a great pairing. The XTSP Mod 22 trigger has proven a pleasure to use and I encourage those interested to read my full XTSP Mod 22 trigger review.

I was also hoping going into this build that it might be an opportunity to add more harmonics data to the Proof Carbon Fiber Barrels review I did a few years ago. The barrel choice also makes sense from a lightweight hunting rifle application standpoint and I have had excellent performance from both the 6.5CM chambered Proof on the Crux build and the one on my Vudoo V-22. These barrels have also proven in controlled experimental conditions to cool more quickly than a similar contour steel barrel, as well as providing many of the shooting characteristics of a heavier barrel, such as a zero that does not wander as the barrel heats up, despite having a weight more similar to a pencil contour. The Proof folks warned me going into this that with 350 Legend, harmonics would probably not be top of the list of my concerns. Although Proof can do pre-fits in 350L, it is not on the normal menu. The reason for this is the performance of the cartridge often results in people thinking the barrel is bad. They were totally right. I absolutely thought the barrel was bad and even sent it back to them to take a look at it. The barrel is not bad. There is absolutely nothing wrong with it. A combination of the exceptionally finicky nature of the cartridge, the bedding, a possible scope issue, and a number of ammo issues, including an ammo recall were all just conspiring against me. I was able to eventually get good performance from both factory and handloads with it. I learned a tremendous amount in the process, frequently felt as dumb as a coal bucket, and will be imparting what I have learned in the upcoming series of articles on precision straight-walled cartridge rifles. A thanks is in order to Proof for working with me on this. Hopefully the information I impart on the subject will result in fewer fully functional barrels being returned and more people being able to get good performance from the 350L as well as other straight-walled offerings. Of course, I will also be adding a section in the existing Proof Carbon Fiber Barrels review with some information from this build.

Lastly, I want to talk about the bottom metal and magazines. I have been on a bit of a roll with Hawkins lately. I picked up a set of their Ultra Light Tactical Scope Rings during my Article on Level Use for the Precision Rifle and found them to be the best set of lightweight rings I have ever encountered in terms of both build quality and design. This is despite being towards the middle of the pack in price for precision rings. Without question, I will be buying more of these rings in the future. I also noticed recently that Hawkins’ one-piece scope mount has become the most popular mount on the PRS series. I am not surprised. They are absolutely on top of their game. One of the first questions I had to answer when planning a custom 700 platform 350 Legend rifle was whether or not I could find an AICS magazine that would work with the cartridge. The 350L takes the same bolt face as a .223 Rem and has some similar case dimensions, but the front of the case is very different and, as I would learn, many magazines will not fit it. For instance, Accurate .223 magazines and Plastic MDT .223 magazines will not fit 350L. However, the metal MDT .223 magazines will work, as will the Ruger AICS 350L magazine, and also the Hawkins Hunter .223 magazine (presuming you have a bottom metal with no protruding magwell, such as the Hunter DBM bottom metal to fit it). I remembered seeing this unique magazine and bottom metal system a few years ago at SHOTShow when they released it. I loved the flush-to-the-stock concept for a very sleek hunting look and the gorgeous all machined aluminum design of the magazine. The quality of fit and finish on both the magazine and the bottom metal are first rate and the adjustable tension mag release lever inside of the trigger guard of the bottom metal prevents any snags when carrying the rifle around. Of course, you can also run the Hunter DBM bottom metal with any other AICS magazines, and I use both the MDT metal .223 mags and the Hawkins Hunter .223 magazine interchangeably. When using these magazines for 350L, the capacity of the Hawkins decreases from five to four rounds and the MDT decreases from ten to eight. Feeding is very reliable in the MDT, with most ammunition excepting some fat hollow points that can be a little over sensitive to the speed at which the bolt is run. The Hawkins Hunter mag is a bit more finicky. It often has difficulty with cartridges diving when fed, as the 350L sits a bit less nose-up in the magazine than the .223 rem would and the spring system in the magazine exerts less spring force on the front of the cartridge than on the rear. The sum of these two factors is that rounds often try to dive into the magazine instead of nosing up into the rifle.

Update 1-14-2025

Nick from Hawkins had an idea to improve the feeding reliability on the Hawkins .223 mag when using it on 350L. On some of their latest spring shipments, the springs have exhibited more closed geometry than in the past. This has lead to nose diving issues such as I experienced. They are now remedying this by stretching the more closed springs such that the top and bottom leafs are parallel to each other. My example had predated this change. I have now done this myself though I may have overstretched mine a bit. The magazine now feeds reliably with a variety of ammo though so problem solved.

Accuracy Testing

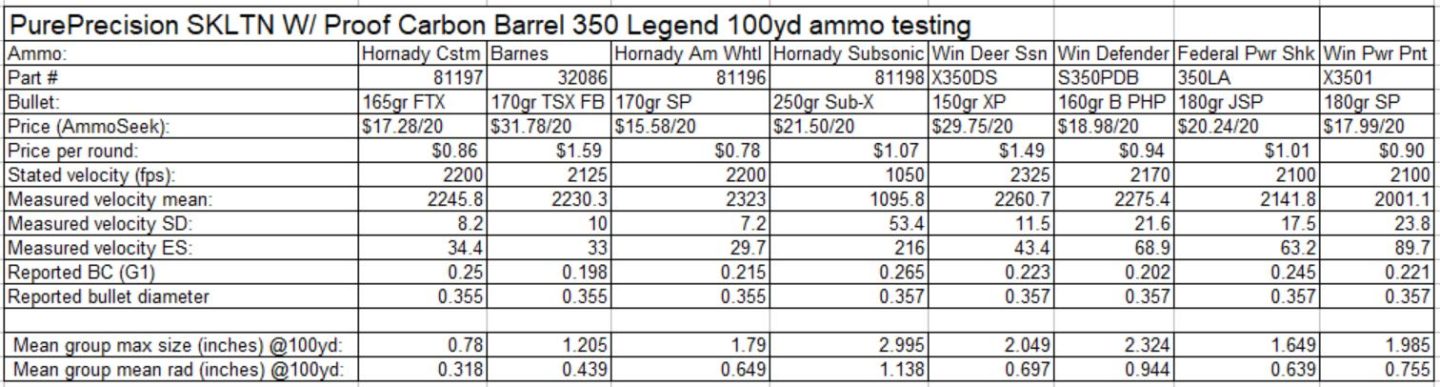

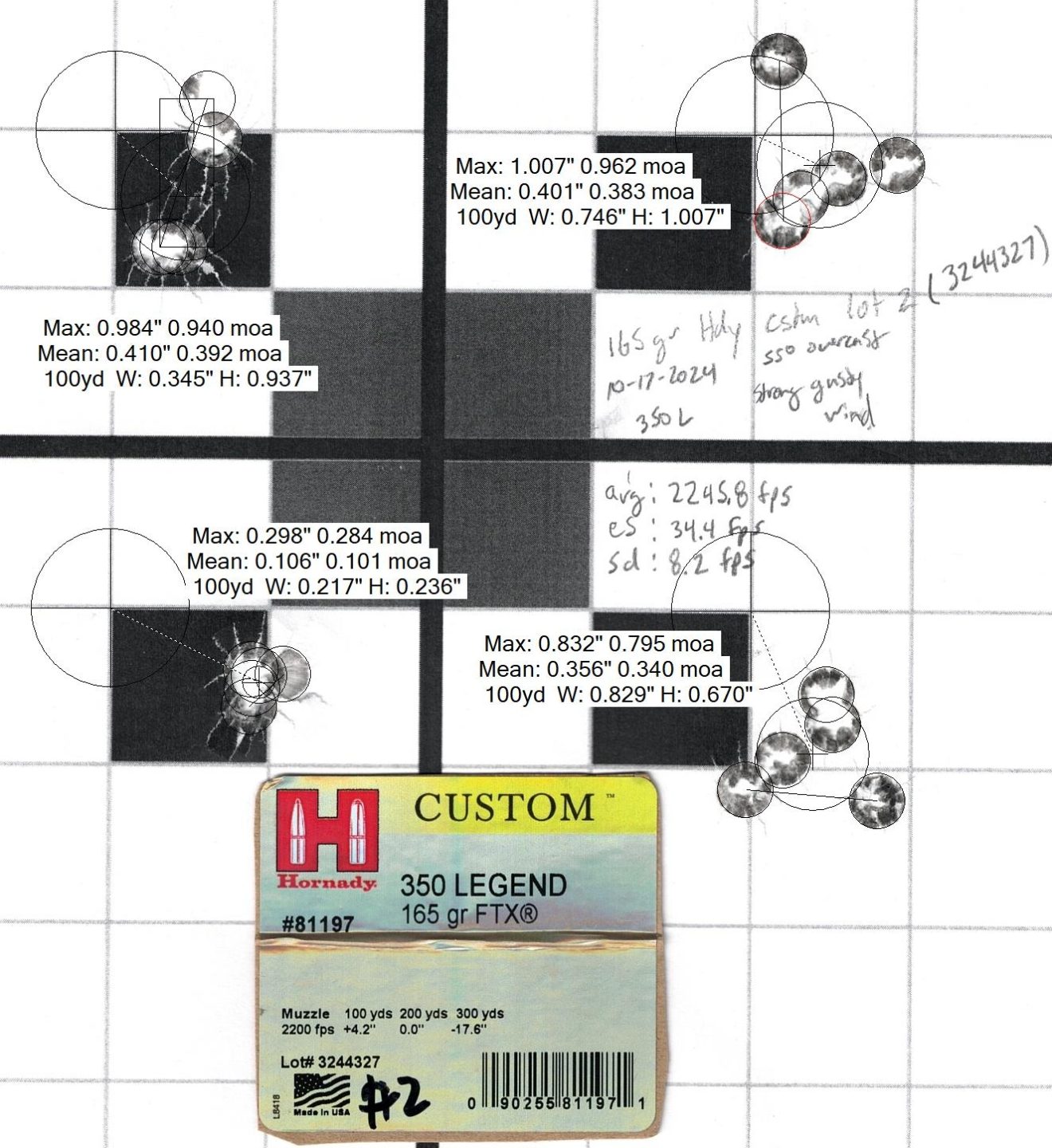

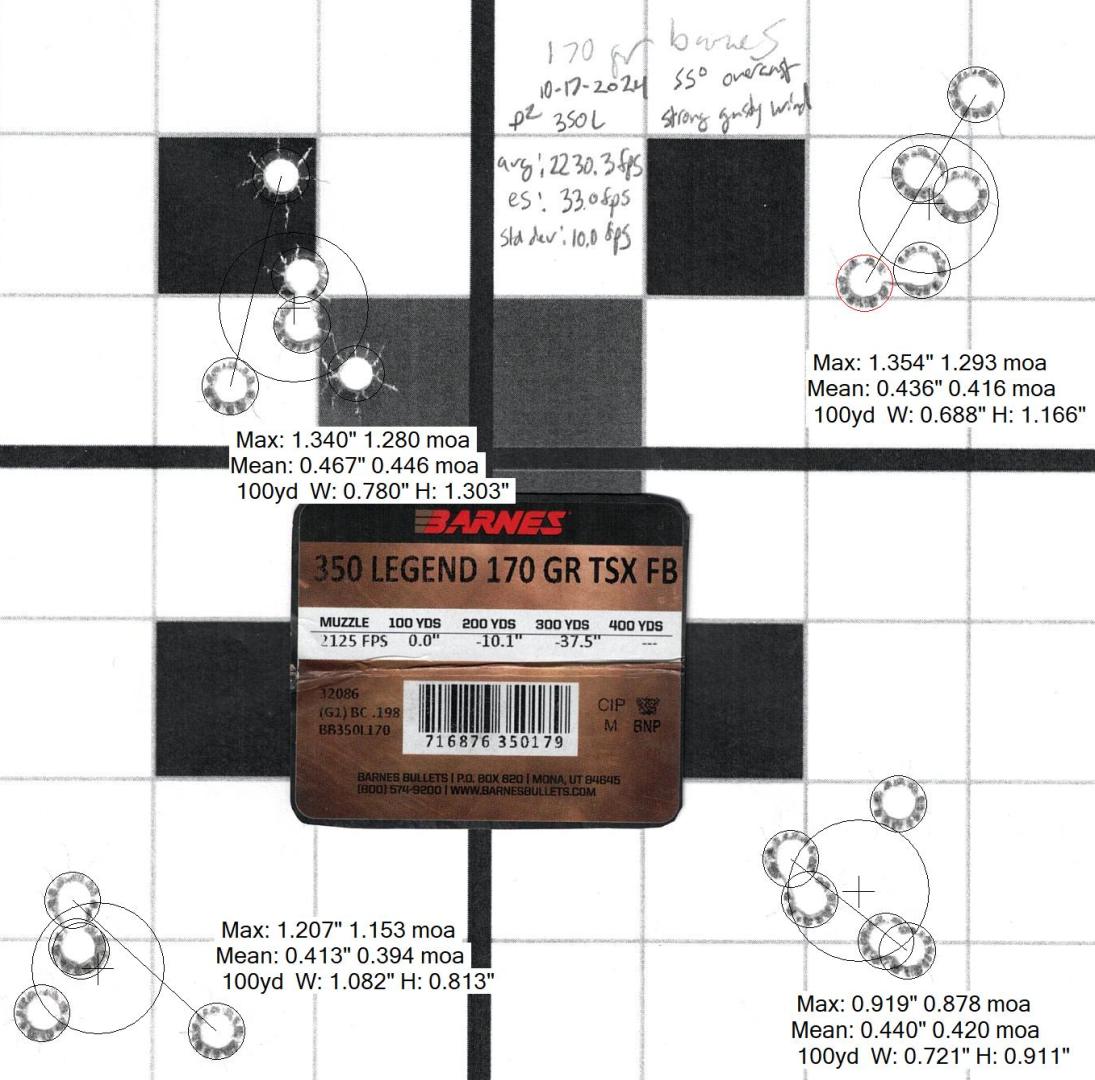

As you can see from the above comparison photo, I have tested quite a number of different factory ammo offerings in this 350 Legend rifle. Additionally, I have done handload testing with four different bullets and three powders. That is a lot of testing. It’s quite a bit more than I did for either the Kelbly Atlas or PurePrecision Crux reviews in past years. Both of those rifles shot quite well with much, or most, of the ammo tested and took little work to find high performing handloads as well. There were also no complicating factors along the way. With this 350L, there were some previously mentioned bedding issues. There was also a bad lot of Hornady Black ammo that showed large velocity fluctuations and was recalled and then discontinued. I may even have a scope issue with one of the scopes I was using. I have not yet had time to fully test and verify this, so I will not be giving any details at this time about that. Without question, the biggest issue is that most factory ammo as well as most handloads just don’t shoot anywhere near the potential of the rifle system though. I have a pile of targets more than an inch tall here to attest to that. Some of these predate figuring out all the rifle’s complications and, boy are they sporty, but about half of the targets made after getting the rifle squared away are still 2+ inch groups. This even includes some handload targets, though the majority of those are between 1” and 2”. All that being said, the rifle can shoot. It’s average five shot group with the better lot of the two lots of Hornady Custom 165gr I have comes out to just over .75” with an average mean radius of .318”. This is right in line with what I had hoped to be able to get from a custom grade 350 Legend and shows the rifle is quite capable.

As I will soon be doing an entire article on accuracy in the 350L as well as handloading for it, I don’t want to write you a multi-page summary of each ammunition here or go into detail on what factors I think commonly cause performance to be much lower than the rifle is capable of. I’m also only about halfway through the handloading work at this time and only now that I have switched to Vihtavuori N-110 powder am I having somewhat more success.

For now, I will say that at this point in the resurgence of straight-walled cartridges, there are issues both with the quality of ammo being produced and with the ability of even quality ammo to perform across a wide variety of user rifles. The 350L cartridge itself also has some design aspects that are suboptimal for accuracy, such as a super long jump to the lands and a long, thin powder column. However, performance can be had and this PurePrecison SKLTN action / Proof Carbon barrel rifle is an excellent platform to figure that out on.

Summary and Conclusion

I am quite pleased with the job PurePrecision has done designing and manufacturing the SKLTN. At 16oz for the titanium short action version and 21oz for the stainless, I believe they are producing the lightest 700 form factor action yet and I can testify it is not lacking the strength to deal with a moderately over-pressure problem cartridge. These actions are available in both short and long variants with standard, magnum, or .223 Rem sized bolt faces. PurePrecison has been very creative and thorough in its weight reduction, finding a number of non-critical areas to machine away that others have not. This significant extra machining is why lightweight action variants are typically priced significantly above their standard weight counterparts, and yet, the SKLTN is amongst the lower priced lightweight actions, despite how much more of this machining has been done on it than on its competitors. That machining is first rate and the overall fit and finish of the SKLTN action is excellent. It is an attractively styled action as well and has drawn nothing but admiration on its range trips.

I believe the SKLTN in stainless or Ti makes an excellent choice for hunting rifles such as the one I have built in 350L to facilitate research into that cartridge. I think the Stainless would also likely make a good choice for weight-sensitive competition rifles for competitions such as NRL hunter, as that would allow more weight budget for other components without any real downside. I have certainly found the SKLTN a pleasure to use in the very significant time I have spent learning about the temperamental 350L cartridge on it. I have even produced some very good performance in spite of the cartridge.

Since I last took a look at one of their products, PurePrecison has expanded rather dramatically. Clearly, the partnership with a machine shop to bring action manufacture in-house is paying dividends in the design, quality of manufacture, and pricing of the SKLTN. It certainly strikes me as a winner. Judging by the bedding and communication issues I had with the Altitude stock, there are probably still a few loose ends to sort out in adding the large Battalion retail operation. Hopefully they already have that squared away as it has been a number of months since the SKLTN rifle arrived at my local FFL.