Table of Contents:

-Introduction

-Why people reload for precision long range

-Quantifying the relationship between powder charge and velocity

-MatchMaster powder measure user experience and impressions

-MatchMaster speed and accuracy testing

-MatchMaster powder measure summary and conclusion

-The Basics of Match grade reloading dies

-The RCBS MatchMaster Competition dies -MatchMaster Competition dies summary and conclusion

Introduction:

These RCBS MatchMaster reviews started in an unusual way in that it began in what might seem the normal way with a form product announcement landing in my e-mail box. Once you get listed as industry media, you get these all the time at a rate of quite a few a day. However, whatever system distributes your e-mail around the shooting world is not very sophisticated so virtually none of what I get is related to precision shooting. In fact, this is the first review to start from such a point. Most reviews start by a company finding me on the Hide and making a request, or with me discovering their product in relation to some particular theme I am examining at the time, thinking it looks compelling, and making a request of them. I find the start of this RCBS review amusing because it actually started in the way that it seems reviews are supposed to start – except that, in my experience, reviews don’t start that way. It is a little like applying to a job that you saw posted in the classifieds with a resume and then being hired. It seems like that is the way things are supposed to work, but in real life they almost never work that way (a little heads up for those of you young and just entering the job market.)

In any case, the MatchMaster measure looked like a great fit for the precision long range shooter. Faster than a ChargeMaster and with .04gr accuracy instead of the .1gr. Lots of guys I know love their ChargeMasters and some even run two simultaneously to save time, so I hit up the contact info on the press release and asked to have a look. RCBS’s media guy was interested and wanted me to try out the new MatchMaster dies as well. Why not: it’s not like I’m not going to be doing a bunch of loading anyway and the bullet window on the micrometer seating die looked quite interesting.

Why people reload for precision long range:

Reloading is often seen as a way to save money and it certainly can be that if you shoot a good amount and your time isn’t worth a whole lot. It is also a rabbit hole that you can fall down, resulting in endless tinkering and lots of equipment purchases. Time value considered, I have never saved money reloading. I don’t even think I saved money when I was reloading shotgun by the five-gallon bucket every couple weeks, but what I produced was noticeably better even considering that was just shotshells.

That brings us to why I reload the precision rifle despite precision rifle being by far the most time consuming and PITA of all things to reload for. I reload because I can reload hotter than factory and with a little better velocity SDs. I can also use exactly the components I want and, perhaps most importantly, match the load to the rifle with respect to seating depth, neck tension, and charge weight. You could say that it is because the ammo produced is better – and it is a little better – but it is mostly that the ammo is better matched to fit the gun and can be substantially hotter if you get lucky on where an accuracy node lands.

Of course, for the ammo produced to actually perform better than factory it has to be made using good equipment. Certainly, 15 years ago you could slap most things together and beat factory ammo, but the factory match stuff you see now is much better. For the most part, it uses good bullets, powders, and brass, and is loaded on some very good equipment. A good bit of the factory match will average better than .5″ 100yd groups in a rifle it fits well, while having SD’s that are typically better than 20fps, even in the very touchy .223 rem caliber, and are often single digit in larger calibers. To exceed this performance with handloads, you have to both fit your load to your gun and also start with good stuff. If you think you are going to use mixed headstamp range pickup brass, ball powder, cheap bullets, entry level dies, and an inexpensive volumetric powder throw to produce match ammo you are very much mistaken.

Quantifying the relationship between powder charge and velocity

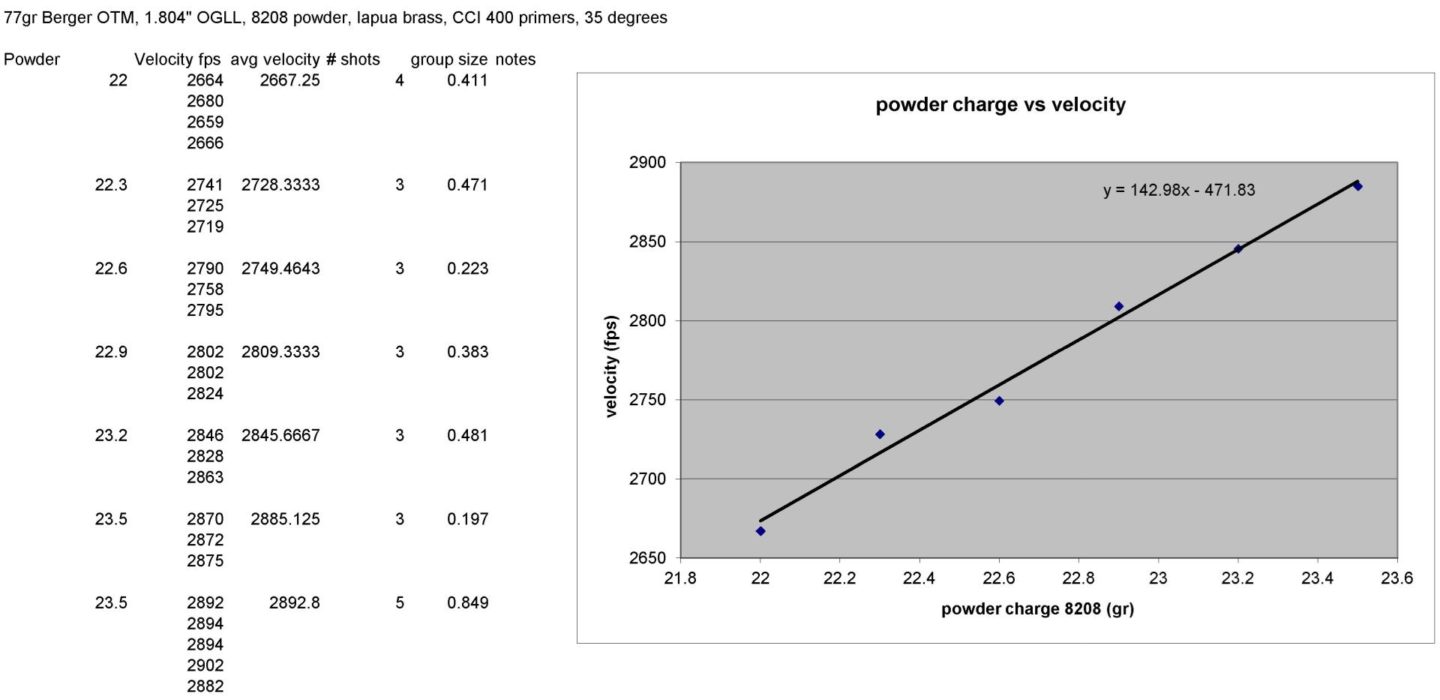

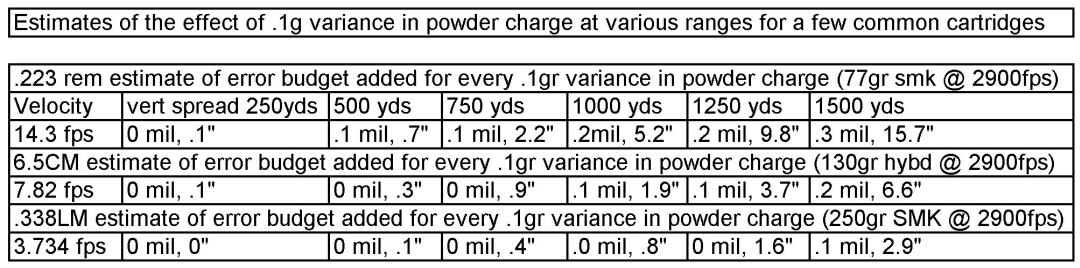

This review got me curious about the relationship between charge to charge variance in powder weight and vertical spread downrange. That is to say, how much an inaccurate powder measure will eat up your error budget. To figure this out, I decided to figure out how much velocity each grain of powder equates to in the .223 I am using for this RCBS MatchMaster review and then run those numbers though a ballistic calculator to see how things change down range. Below you will see the plot of velocity vs. powder charge.

This was actually the first time I have ever plotted one of my load development powder charge targets. I was honestly a bit surprised to see how linear the relationship between powder charge and velocity is. That wasn’t what I expected to see. Velocity is not actually related to energy in a linear fashion. The equation for the energy of an object in motion is Kinetic energy = (1/2) mass * Velocity^2. That equation would not suggest a simple linear relationship on its own, let alone when the complications of case capacity and primer propellant are added. I am sure that if you stretched out powder weights tested enough, things would eventually get strange looking, but here in the sweet spot of pressure and velocity, where we actually shoot, things are definitely quite linear. How surprising! The best fit line of velocity = 142.98 (grains of powder) – 471.83 indicates that one grain of powder is worth 142.98fps, which would make .1 grain worth 14.3 fps. I ran that number through a ballistic calculator to find how much vertical spread to expect at various ranges and then scaled it to estimate for 6.5CM and .338LM to get an idea of what to expect in some of the other, larger, calibers commonly used.

So, we can see from this that .1gr of variance in charge weight does eat up substantial portions of our error budget at distances we commonly shoot when using smaller calibers, though not so much with a .338LM. I think this has been a useful exercise in helping us think quantitatively about the downrange consequences of our equipment choices.

MatchMaster powder measure user experience and impressions

The Concept of the RCBS MatchMaster powder dispenser is really of an all-in-one solution for powder handling for the precision shooter. The unit incorporates a good scale calibration weights, and both volume and trickle dispensing tubes. It also has a bluetooth app for keeping load data as well as custom tuning the dispensing stages. This gives you a lot of flexibility in how you use it, even to the point of fine tuning each specific dispensing stage to minimize charge dispensing time on you favorite load. I would classify it as a very easy solution for powder dispensing. The scale takes about 20 minutes to warm up and by that time you will have read enough of the manual to be ready to go yourself.

I have encountered a few quirks along the way that were really the only hitches in the easy nature of the system. The first is that smartphones are what they are and the RCBS program initially wanted to crash on mine when interfacing with the measure. The solution to this was not to reboot the phone or powder measure, but actually to log out of the program on the phone and then log back in. Go figure. In keeping with the vagaries of technology theme, my MatchMaster often has its open drain warning tripped when powder is initially added. I am not sure why this is. Perhaps a kernel of powder has gotten lodged in just the right place or maybe the Tubb dust I’m using has coated a sensor it shouldn’t have. My solution has been to hook up the drain pipe to the powder measure and then open and close the drain port (obviously, with the powder jar below it). That seems to clear out the ‘improper port open’ reading. On the theme of drains, whenever you are draining the powder to put the thing away or change powders, leave both the platen attached and pan on it. Those tubes have a lot of powder in them and like to spill it out. Also, do not expect that they are completely empty just because you hit the trickle key when draining to spin them clean. There is a portal to some other dimension in those tubes and occasionally powder will drop out from another world. I swear, they are never completely empty. To use the measure you will also need about one-third (1/3) pound of powder in the hopper. That’s just the nature of how the tube system works and the geometry of the hopper. It is not capable of metering out the last scrapings from your powder jar. The measure has leveling feet and a bubble level for you to adjust it to level, but it seems that maybe the engineer calibrated these such that the baseline was measured with feet screwed all the way in instead of in the middle of their travel range. So…. you will likely need to put a little shim under the back of the measure to be able to level it with the feet. Whoops for him. Lastly, do not try to use the MatchMaster attached to the same local electrical supply as an electrical discharge machining unit. It might seem obvious that a machine which cuts steel by blasting away at it with high voltage sparks might muddy up the current a bit and cause precision measurement instruments relying on tiny changes in electrical resistance problems, but I didn’t think about it and found out the hard way that its zero wanders in that situation.

MatchMaster speed and accuracy testing

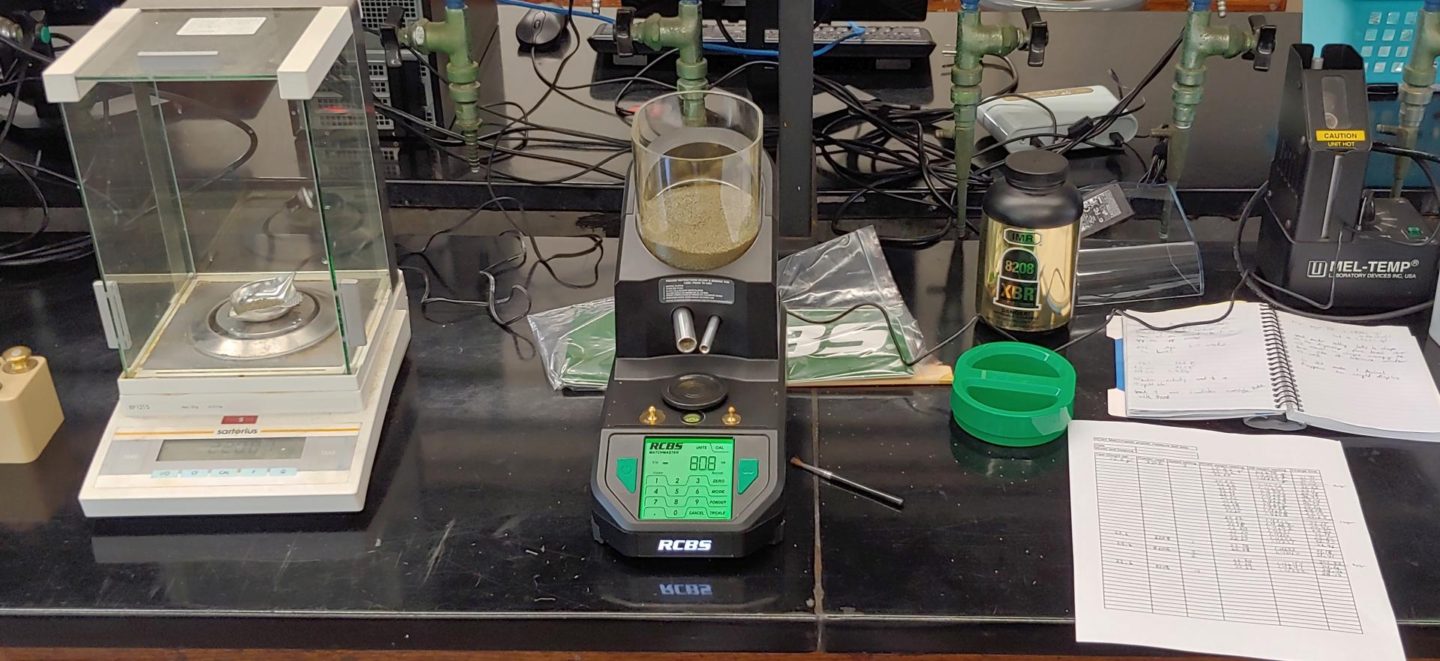

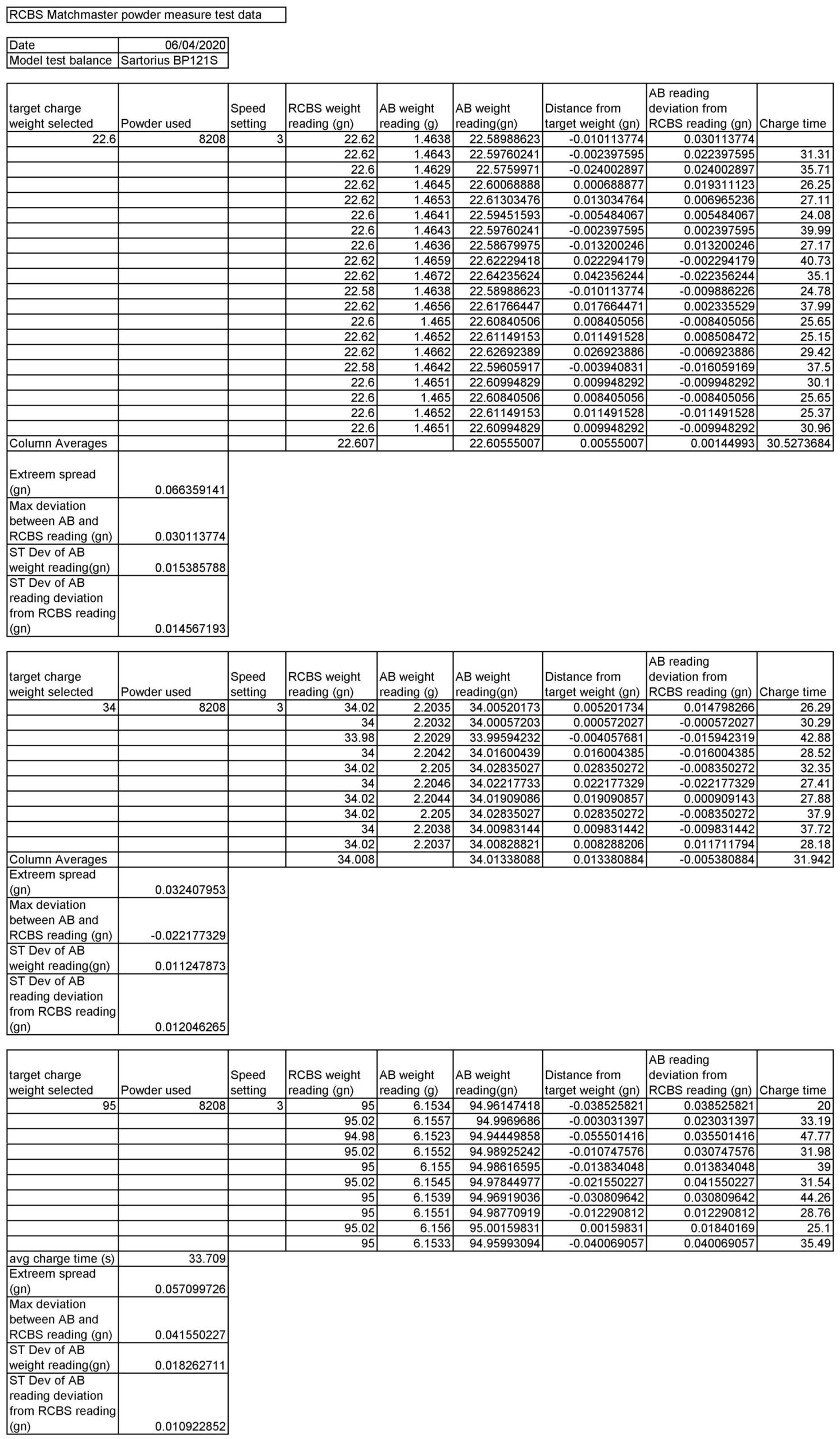

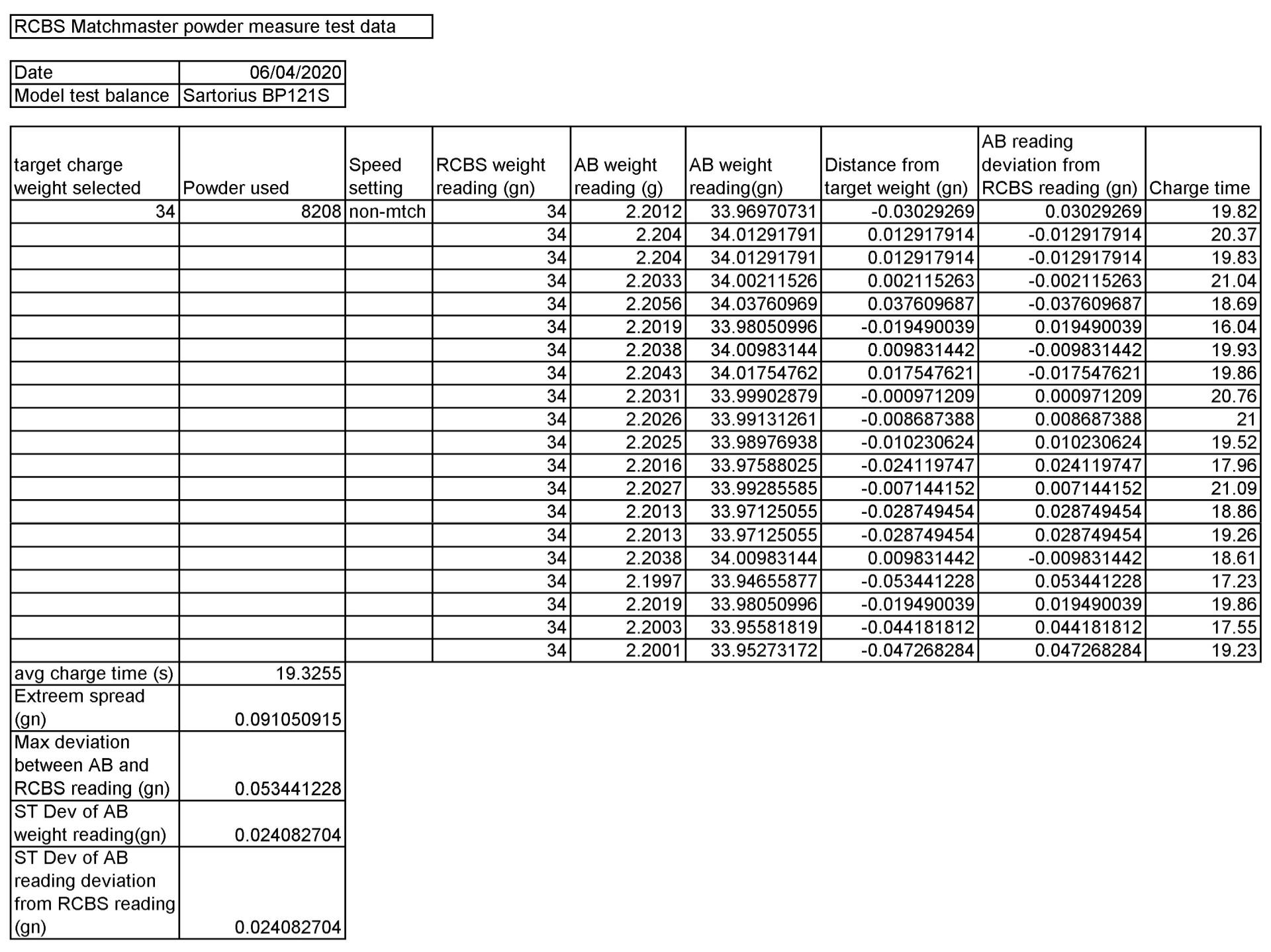

RCBS claims accuracy to .04 grains in match mode and .1 grains in normal mode on their website. They have clarified this to me to mean all charges will be within + or – that .04 or .1 grains from the user’s setting. My testing indicated that the measure is substantially better than this on both fronts. For testing, I weighted charges thrown on the MatchMaster on a Sartorius BP121S analytical balance capable of measuring to .0001 grams. I measured at 22.6gr, 34gr, and 95gr to sort of cover some common rough weights that a shooter might be using with a .223rem, 6.5CM, and .338LM, though you obviously would not be using the same powders for all three of these. Presumably, dispensing times will vary some with the longer grained powders typically used in .338LM, but I used the same powder to test all three because I don’t even have any powder suitable for a .338LM and the powder choice will in no way effect the scale’s measurement accuracy anyway. We will start out with the match mode testing.

Data from testing the RCBS MatchMaster in match mode on a Sartorious BP121S analytical balance

There are a couple of things that jump out to me in the data and analysis. First, the dispenser is a good deal better than +/- .04gr. That would yield an extreme spread of .08gr, and it was better than that at all weights. The worst it did on any set of match mode measurements was .066gn extreme spread. The scale on the MatchMaster reads to .02 and it is set up to stop dispensing on values of +/-.02gr. Like most digital scales, however, it is not actually good to the .02gr it displays all the time. Most of the time it is reading within the .02gr resolution it displays, but occasionally it is off by a little more than that, especially when you get up to the 95gr charge range. The MatchMaster scale appears to be best optimized near the 34gr area where most shooters will be loading. Here it was most precise, with an extreme spread of just over .03gr. I believe that the 8208 powder is somewhere in the vicinity of .015gr a kernel so the dispenser is doing about +/- a single kernel from ideal in its sweet spot with a standard deviation that is less than the kernel weight. The MatchMaster is not quite weighing to the kernel every time, and indeed its scale alone is not quite accurate enough to do that, however it is dispensing to the kernel about 2/3rds of the time. The next thing I noticed is that the big tube that does the bulk part of the charge is so fast that heavier charges take negligibly longer to load than light ones. Roughly 34 sec for 95gr charges vs. 31 sec for 22.6gr charges. You are really not missing any speed for not having a volumetric drop stage like some competing measures. The speed difference between those measures and this appears to me more due to the setup and function of the trickle part of the cycle and the related settle speed of the scale. Lastly, the dispenser had 9 overthrows out of the 44 total throws on match mode and no overthrows on standard. These overthrows went .04 over on the measure and I tossed them. Grains would sometimes clump together in the dispenser tube and come out a couple at a time. The trickle tube is just a little shorter and a little steeper than ideal and I don’t think any custom trickle settings are going to prevent this, though I do think some powders will be much better than others in this respect.

When dispensing in standard mode the scale now only reads to the .1gr instead of the .02gr. However, I noticed that the dispenser does not stop dispensing when the weight reads the correct number of grains so internally it is clearly still measuring more accurately than that and acting according to those internal measurements even if it isn’t showing them to you. Unsurprisingly, this results in it doing substantially better than the +/- .1gr that it claims and that the ChargeMaster also boasts. On standard mode, the extreme spread of the Match master was actually better than twice as good as advertised at .091gr. The SD of its charges was .024gr. Dispensing time averaged 19.33 seconds, slightly better than the 20 seconds advertised. This was all to the good, though I am curious if anybody is going to use this nicely calibrated faster mode over the more finicky higher precision match mode. The tinkerer in me wishes that they left all the readout digits active in the non-match mode so you could try running more charges faster, manually tossing the farthest off ones, and maybe end up ahead in total loading time. In any case, the MatchMaster in standard mode certainly torches a ChargeMaster or two any way you look at it.

MatchMaster powder measure summary and conclusion

I think I have given you a lot of good data in this review quantifying how variance in powder charge translates to variance in fps at the muzzle and vertical dispersion down range. I have also given you a pretty good idea what to expect from the MatchMaster in terms of speed, accuracy, and precision. The measure’s scale seems to be best optimized for the typical 20-40gn ballpark charge weights that most shooters will do. It is a little better here, in terms of both accuracy and precision, than it is up around 100 grains where magnums will be. In match mode, you can expect the MatchMaster to weigh charges in just over 30seconds that will not always be exactly to the kernel, but will be so about 2/3rds of the time.

The MatchMaster is very easy to use and can function with or without interfacing it with the bluetooth app. What few hiccups I encountered where mild, mostly software related, and easily worked around. There is even some capacity to tinker with the dispenser’s function through custom, savable, dispenser settings that let you fiddle with each stage’s settings using easy sliders in the smartphone app. RCBS claims you can get down to averaging in the 15-20 second range in match mode with custom settings.

Basically, I think that most long range shooters are going to be satisfied with the speed and performance of the MatchMaster. Where I think there will be arguments are with respect to the cost and single year warranty. RCBS has these at around $900. That doesn’t put it between a ChargeMaster and an AutoTrickler, but basically neck and neck with the AutoTrickler. I question why they did this. Given the integrated design, avoidance of CNC machined components, and economies of scale a company the size of RCBS can wield, I expect that they could come in lower. I think the MatchMaster would slay at the $600 price point between the ChargeMaster and an AutoTrickler, whereas at $900 there is a much more complicated argument between it and that competitor.

The basics of match grade reloading dies

Like anything else in the shooting sports, there are many levels of performance in reloading dies. I will break these down into the three basic tiers of standard, match, and custom. For the purpose of brevity, I will characterize standard dies as having the minimal amount of adjustments necessary to make functional safe ammunition; match dies as having additional adjustments such that you can fine tune them to fit particular brass and bullets; and custom dies as being actually cut for your specific rifle chamber and components.

With regard to the sizing die, match tier dies have interchangeable neck size bushings instead of a single neck size that is part of the sizing die. This allows the reloader to experiment with different neck tensions, set up the die differently for different brass, or neck turn the brass and then set the die properly for that altered brass. Interchangeable neck bushings also allow you to work the brass a lot less with each resizing. This translates into significantly longer brass life – unless you are going to prematurely stretch out the primer pockets anyway as many long range shooters often do with particularly hot loads. Typically, match grade dies can also be set up to be used with or without an expander ball whereas standard dies must always be used with an expander.

Match grade seating dies will have even more departures from their standard counterparts. First, the seating depth on match grade dies will be adjusted with a very finely threaded micrometer. This will allow for easier fine adjustment of seating depth. The seating stem itself will also be shaped to more evenly distribute the seating force on the bullet ogive and not smash the tips of long, thin, VLD, or tipped bullet geometries. I think the most important feature of a match seating die is the sliding case alignment sleeve that RCBS calls the bullet guide bushing. When the case is raised in the press, this sleeve hugs the top of the case and moves up with it, holding the bullet in proper alignment with the case throughout the entirety of the seating process. This is a big change over standard seating dies where the case doesn’t touch the die until the very end of the seating process and the bullet can easily get started a bit crooked. I think that failure to align the bullet perfectly at the start is deadly to down range accuracy. I believe starting out of alignment very slightly damages the bullet and case so that you often can’t tell just by looking at them, but in such a way that downrange performance suffers greatly. Before I went to a seating die with a sliding sleeve, I could never get my reloads to the accuracy level I wanted and I think that bullets getting started a little off kilter was why. To hell with seating dies without sliding sleeves and to those imitation match grade seating dies that have a fancy looking micrometer to adjust seating depth slapped on top but no sliding sleeve to properly align things inside.

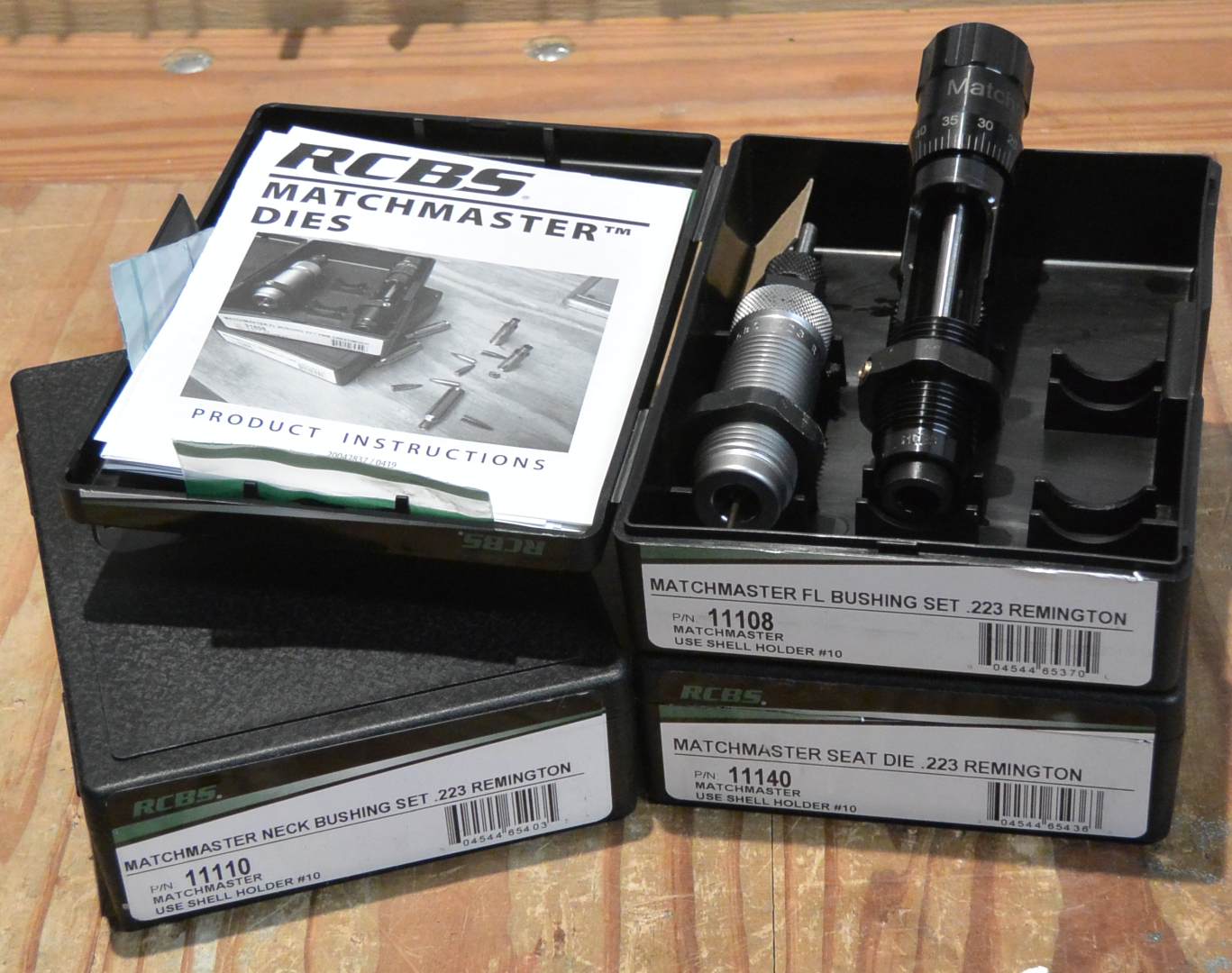

The RCBS MatchMaster Competition dies

The MatchMaster resizing dies do not really differ in any meaningful way from other match grade bushing-type dies I have encountered. To use it, you of course need to first get some bushings. They recommend measuring your case neck thickness, doubling that, adding bullet diameter, and subtracting .001 to get your neck bushing size. I suggest subtracting .002, as .001 was way too loose for me and that was without using the expander. In any event, you should buy a bushing above and below your expected size in addition to the expected size, as you may find things too tight or loose or want to try a little different neck tension. RCBS makes bare steel and coated bushings, but the coated ones seem to be harder to find. In practice, I found the sizer die to work just fine, though it is pretty indistinguishable from other match grade dies I have encountered.

The MatchMaster seating die is more unique. In addition to having a sliding alignment sleeve, VLD friendly floating stem, and micrometer adjust bullet seating depth, it also has a window to load the bullets through literally cut out of the side. This bullet window is where the RCBS MatchMaster seating die differs from anything else I have seen. The way that this seating die works is that you drop the bullet, tail down, in the die through the window in the top. The bullet falls into the sliding alignment sleeve and comes to rest on the edge of an o-ring that stretches across a little channel in the alignment sleeve to form a stop. The bullet sits quite low in the die, in what is essentially a long tubular alignment section not much larger than the bullet diameter. There is very little play between the bullet and this alignment section. In the picture below you see a fairly long 69gr projectile in the .223rem die. You next raise the case in the press into the bottom of the die, where the case fits into the bottom of the sleeve and raises it to the seating stem. The stem and bullet fit though the sleeve and nudge the o-ring aside, pushing the bullet into the case. In practice it’s a slick system which prevents pinched fingers and craned necks while also requiring less ram stroke distance than seating in competing dies without windows do by a pretty substantial amount. While I don’t think that the seating window probably results in any improvement in alignment or end product over any other quality sleeve type seating dies, it is much more comfortable to use for the guy doing the reloading. The die itself also has a very nice shiny black finish and is quite beautifully machined. The feel of its micrometer adjust is really good and its incremental markings proved to be spot on accurate. Also spot on was the consistency of seating depth on the resulting rounds. This included the VLD’s that I loaded whose geometry was well accommodated by the seating stem.

MatchMaster Competition dies summary and conclusion

Without question I’m going to end up buying more of these MatchMaster dies. The resizing die may not be better or worse than many other competing dies, but the seating die is something special. The bullet window system RCBS has come up with is faster and more comfortable than anything else I have tried. A real step up in user friendliness. On top of that, the fit and finish are by far the best I have seen on a die. It looks as nice as a custom rifle and the micrometer both feels great and is spot on when it comes to the accuracy of the markings. The rounds produced were also spot on when it came to the consistency of the seating depth and this was true for VLD’s as well as more conventional shaped bullets. The feel transmitted back to you through the press when reloading can tell you a lot and I was quite pleased with the consistency and smoothness using both of these dies. Lastly, the MatchMaster die sets actually seem to be selling for a little less money than competing designs. These dies are a definite win.