I went to the range this afternoon to shoot my new AR build. Components are:

22" Creedmoor barrel (from a big name maker, but I don't want to post their name for now. I want to give them a chance to get back to me first)

Mega Maten upper and lower

DPMS BCG

JP adjustable gas block

Surefire brake

Apex rifle length hanguard

Atlas bipod

Giessele SSA-E

H3 Buffer

Troy Buffer Tube

CTR Stock

Nightforce F1 Mil Mil

Nightforce Unimount 1.125" height

During assembly, the original bolt I bought didn't pass headspace test with the no go gauge. I bought 3 more bolts from Brownells. All 3 passed and were dimensionally identical as far as I could tell with calipers, so I just picked one and went with it.

Today at the range was the initial firing. Conditions were about 70 degrees with a light rain. No issues with the gas system. I started out at 2 turns from closed per JP's instructions. I turned it down about a quarter turn each shot until the bolt failed to lock on round 5. I cleaned the barrel in between each shot as well for these 5 shots.

The problem though is that I seem to be having some pretty visible over pressure signs on the brass, and the last 2 of the 5 shots popped out the primers.

I have emails out to the barrel maker and to Hornady. In the mean time, does anyone have any idea what would cause this? As far I can tell, it could just be hot ammo or something wrong with the chamber. As I mentioned above, headspace was checked and passed (closed on go gauge, won't close on no go gauge). I know there are other chamber dimensions that could be out of spec, but I am not too familiar with that.

After two popped primers I figured it was time to stop for the day and consult the more knowledgeable minds on the hide as well as the manufactures. Any input is appreciated. Thanks!

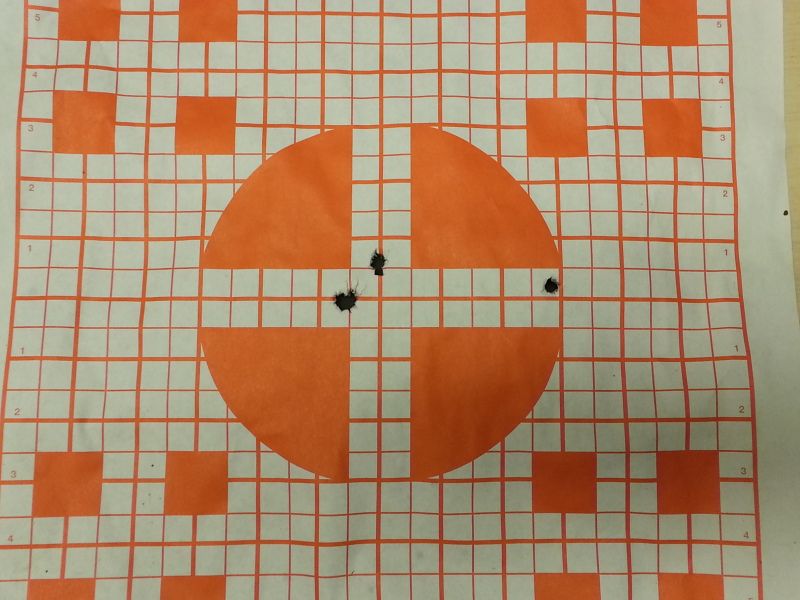

This is at 50 yards. Round 1 was to the right. Scope correction was made and then rounds 2-4 are on top of each other. I wasn't on the gun for round 5 since I already had 1 popped primer at that point...

22" Creedmoor barrel (from a big name maker, but I don't want to post their name for now. I want to give them a chance to get back to me first)

Mega Maten upper and lower

DPMS BCG

JP adjustable gas block

Surefire brake

Apex rifle length hanguard

Atlas bipod

Giessele SSA-E

H3 Buffer

Troy Buffer Tube

CTR Stock

Nightforce F1 Mil Mil

Nightforce Unimount 1.125" height

During assembly, the original bolt I bought didn't pass headspace test with the no go gauge. I bought 3 more bolts from Brownells. All 3 passed and were dimensionally identical as far as I could tell with calipers, so I just picked one and went with it.

Today at the range was the initial firing. Conditions were about 70 degrees with a light rain. No issues with the gas system. I started out at 2 turns from closed per JP's instructions. I turned it down about a quarter turn each shot until the bolt failed to lock on round 5. I cleaned the barrel in between each shot as well for these 5 shots.

The problem though is that I seem to be having some pretty visible over pressure signs on the brass, and the last 2 of the 5 shots popped out the primers.

I have emails out to the barrel maker and to Hornady. In the mean time, does anyone have any idea what would cause this? As far I can tell, it could just be hot ammo or something wrong with the chamber. As I mentioned above, headspace was checked and passed (closed on go gauge, won't close on no go gauge). I know there are other chamber dimensions that could be out of spec, but I am not too familiar with that.

After two popped primers I figured it was time to stop for the day and consult the more knowledgeable minds on the hide as well as the manufactures. Any input is appreciated. Thanks!

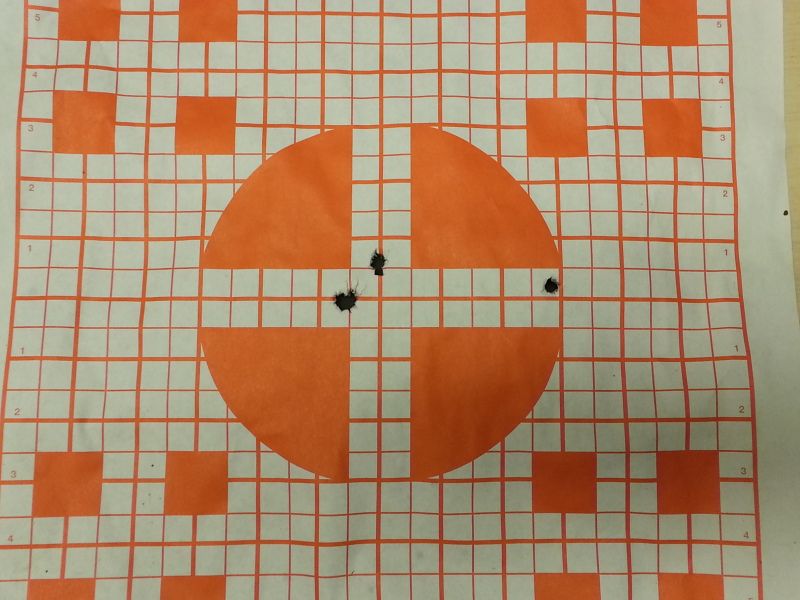

This is at 50 yards. Round 1 was to the right. Scope correction was made and then rounds 2-4 are on top of each other. I wasn't on the gun for round 5 since I already had 1 popped primer at that point...