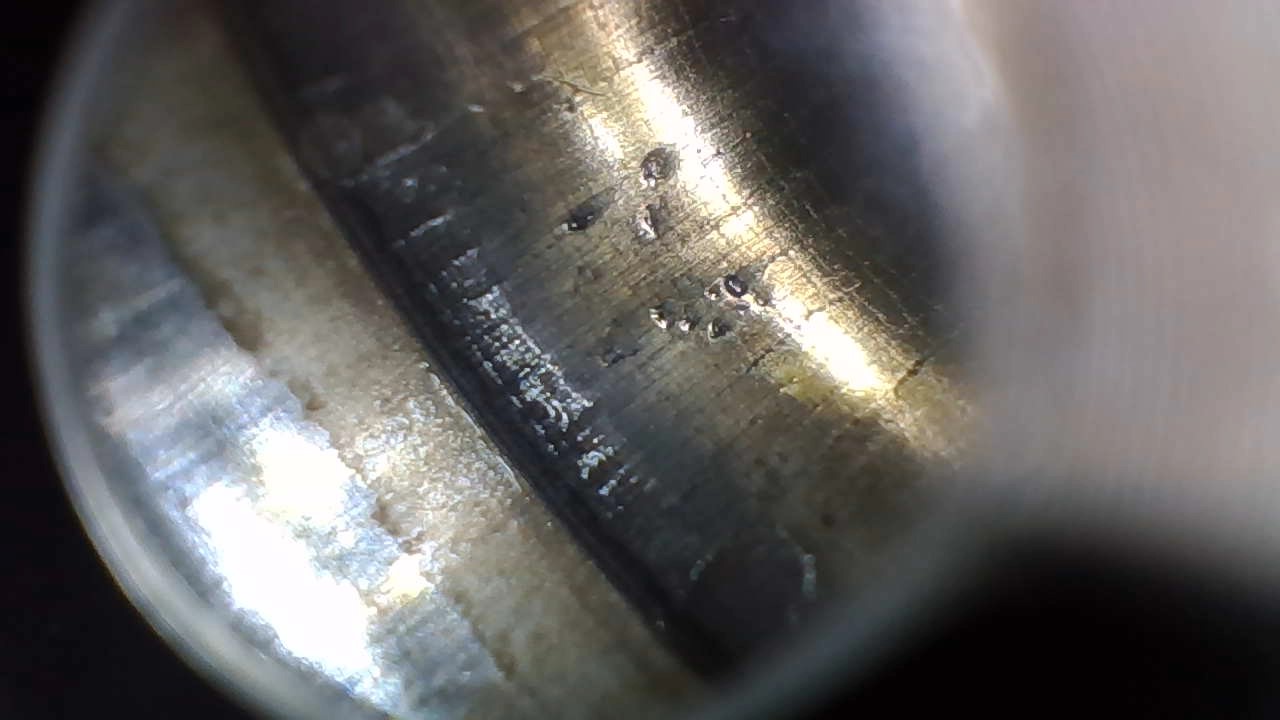

I have seen my fair share of pitting down a barrel and general throat erosion, but I have never come upon anything quite like this. Anyone got any ideas as to cause? This is a 300 PRC barrel with exactly 373 rounds through it. There is nothing else anywhere throughout the chamber, or around the rest of the throat or length of the barrel. The rest of the barrel is pristine....

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Unknown cause of pitting in Throat (pic)

- Thread starter Glckcmndr

- Start date

Brand blank? I do not have an answer, however I just had a 6GT barrel go tits up after 600 rounds. Lakebed, pitting, looked like it had 6k on it. My barrel smith replaced it. It was not run hard, Berger 105s at 2990 with 32.5 of N150. All in the throat, rest of barrel looked fine. My smith had no answers either. Real head scratcher. I went to RL15.5 now. Not sure if it was a bad barrel or a powder issue.

I would rather not post who the maker is until they have had a chance to look at it and give their opinion. I work in the industry and I cant stand people posting stuff without knowing all the facts that they can first. I will say this, its a TOP tier manufacturer that I would not expect to have bad steel.... but that is what I am thinkingBrand blank? I do not have an answer, however I just had a 6GT barrel go tits up after 600 rounds. Lakebed, pitting, looked like it had 6k on it. My barrel smith replaced it. It was not run hard, Berger 105s at 2990 with 32.5 of N150. All in the throat, rest of barrel looked fine. My smith had no answers either. Real head scratcher. I went to RL15.5 now. Not sure if it was a bad barrel or a powder issue.

Is it possible your looking at a spot that has carbon build up with chunks of the carbon pitted?

The photo is very clear, pitting is in the metal, not carbon.

Unfortunately, no, these are deep pits. like what I have seen on a breach face with punctured primers.Is it possible your looking at a spot that has carbon build up with chunks of the carbon pitted?

This is my proof carbon chambered in 308win. Less than 100 rounds through it. It wasn’t grouping as well as it normally does this past weekend. Broke out the ol idiot scope when I got home and had a mild panic attack. The barrel is of course in damn good shape everywhere else. Just that one spot in the freebore.

Attachments

Why do you think this isn't normal? I have a 6.5 barrel that has one spot that is worse then what your picture is showing, more rounds down the pipe though.

Just unexpected with a low easy round count in a non-overbore cartridge. If it becomes a real issue I’ll see if it can be set back. Proof said it was from moisture damage or leaving solvent in the barrel neither of which have occurred as this was only the second time to clean it with solvent. First was following their break in instructions.Why do you think this isn't normal? I have a 6.5 barrel that has one spot that is worse then what your picture is showing, more rounds down the pipe though.View attachment 7833385

How did you clean it?Just unexpected with a low easy round count in a non-overbore cartridge. If it becomes a real issue I’ll see if it can be set back. Proof said it was from moisture damage or leaving solvent in the barrel neither of which have occurred as this was only the second time to clean it with solvent. First was following their break in instructions.

Almost looks as if there was porosity/voids in the parent material and the surface gave way. Edges do not seem rounded or worn as if heat or some type of corrosive agent was used. Looks "flaked". I have seen this in mill runs of materials on occasion, though rare, and never have seen it in a barrel blank. Curious as what your barrel maker has to say on this one.I have seen my fair share of pitting down a barrel and general throat erosion, but I have never come upon anything quite like this. Anyone got any ideas as to cause? This is a 300 PRC barrel with exactly 373 rounds through it. There is nothing else anywhere throughout the chamber, or around the rest of the throat or length of the barrel. The rest of the barrel is pristine....

The first time? Per their instructions. Wet patch after 3 shots and cool, dry patches until bore dry, shoot more, repeat. It never did copper foul any so I stopped at round two of the procedure. This issue had to occur in the last 6mo or so. The break in occurred in early 2019 and I’ve scoped it yearly. It’s a hunting rifle so I’m not out banging away at the range. The barrel never had any issues so I’ve just dry patched it and followed up with a light oil patch after firing before putting it away in the safe for storage.How did you clean it?

Picture here after a dry patch before cleaning.

Attachments

Last edited:

I had a few barrels spun up by a reputable smith a year ago. All 3 barrels are the same make, and it just so happens my 300 PRC has really bad pitting in the neck of the chamber. I'd be interested to know who the manufacturer of your blank was because it looks just like the flaked off metal I am seeing. I thought at first that it was stubborn carbon but I got a good look at it with the bore scope and it looks like the parent material had porosity and was cut really thin and gave way. I did the break in as per the instructions also; and I used Bore Tech carbon remover and a Losso nylon brush for all the cleaning I've done. I also took the precaution of using a bore guide and used a bore mop to dry things out after each cleaning pass. I haven't seen copper fouling in the 140 rds I've put through the rifle either; and the barrel cleans out quickly and easily. I may be able to understand if this were taking place in the throat...maybe...but it is the neck of the chamber. I've never seen this before. Maybe shoot me a private message? I sent the Smith an email and am waiting on a reply.I have seen my fair share of pitting down a barrel and general throat erosion, but I have never come upon anything quite like this. Anyone got any ideas as to cause? This is a 300 PRC barrel with exactly 373 rounds through it. There is nothing else anywhere throughout the chamber, or around the rest of the throat or length of the barrel. The rest of the barrel is pristine....

Attachments

To me it looks like heat checkering starting to chunk off. 300 rounds is proabaly close to a quarter of the barrel life for a 300prc.

@Frank Green is a guy who has looked in more barrels than most of us have looked at.

@Frank Green is a guy who has looked in more barrels than most of us have looked at.

Any chance the OP is using Wipe out Foam with Accelerator? I had this happen on a Krieger 6BR, as well as the outside of a Brownells branded AR-15 barrel extension where it seeped in between the receiver and extension. Could be coincidence, though I really don’t believe in that.

That said, I switched cleaning routines and the shit still shot lights out when I pulled it for a Dasher barrel so… fuck it. At the end of the day that’s really all I care about.

That said, I switched cleaning routines and the shit still shot lights out when I pulled it for a Dasher barrel so… fuck it. At the end of the day that’s really all I care about.

Wet patch with what?The first time? Per their instructions. Wet patch after 3 shots and cool, dry patches until bore dry, shoot more, repeat. It never did copper foul any so I stopped at round two of the procedure. This issue had to occur in the last 6mo or so. The break in occurred in early 2019 and I’ve scoped it yearly. It’s a hunting rifle so I’m not out banging away at the range. The barrel never had any issues so I’ve just dry patched it and followed up with a light oil patch after firing before putting it away in the safe for storage.

Picture here after a dry patch before cleaning.

If it's in the case neck area it should have nothing to do with heat checking/cracking at all.To me it looks like heat checkering starting to chunk off. 300 rounds is proabaly close to a quarter of the barrel life for a 300prc.

@Frank Green is a guy who has looked in more barrels than most of us have looked at.

It's either some carbon sitting in there or if the reamer tore during chambering it will be below the surface. If it's below the surface then you should be seeing the brass with marks of swelling/sticking up etc... on the case neck.

Also if it's some sort of corrosion from the cleaning solvents... it should've eaten the metal away and basically leaving a pocket and when you fire the brass the brass will flow into the pocket area and when you extract the round the brass in that area would be proud/sticking out.

I had an original 1903A3 rifle. The chamber had a bad rust spot in it. You fired the round and it extracted with no issues but there was a noticeable bulge in the case body. Gun shot like a million bucks and was virtually in new condition otherwise. I would shoot it but I wouldn't reuse/reload that case after firing.... I would throw it in the garbage.

I didn't look well enough. I took from the title it was in the throat, but the picture looks like the case neck area.

Similar threads

- Replies

- 21

- Views

- 1K

- Replies

- 30

- Views

- 1K