Hi, I am building a M110 clone and is using a Nefarious arms M110 barrel, I am having issues with case stuck in chamber and the case head been ripped off, I see there is a lot of people on here saying they have the same issue but I also have a issue where the case gets marred up really bad by the chamber, just want to see what could cause the marring the red primer is igman which is not a good round I know, it would some times eject and sometimes stuck in the chamber, I also tried Hornady, Hornady ejected fine but also had marring on brass

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Having trouble using the site?

Contact support

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AR10 pulling rim off and marring on brass

- Thread starter Guan999

- Start date

Pics show a lot of marks on the brass just below the shoulder indicate the chamber was poorly finished.Hornady ejected fine but also had marring on brass

That is also what I was thinking, is this something that can be polished by a gunsmith or I need to go back to the barrel manufacturer?Pics show a lot of marks on the brass just below the shoulder indicate the chamber was poorly finished.

It might just be a little rough that will eventually smooth out, or it might just need a little polishing/honing by the mfr. Yeah. I know some people who just wrapped steel wool or green scotchbrite around a 45 ACP brush with some oil and "buffed it out, but I would contact the vendor. No sense in paying a smith to do what should have been done in the first place.

Check head space. If it’s fine polish the chamber.

Normally I would say send it to them for repair but reading reviews it may be years to get it fixed

Normally I would say send it to them for repair but reading reviews it may be years to get it fixed

I would have thought he checked head space as the post said he was building but yes he should ....good callCheck head space. If it’s fine polish the chamber.

Normally I would say send it to them for repair but reading reviews it may be years to get it fixed

I had/have the same issue with a cheaper .308 barrel chambered in .308. It only does it with 7.62x51 ammo though; similar, but not the same specs.

That barrel seems to eat all .308 ammo without issue, so I suspect it’s mostly a matter of tolerance stacking in the throat and chamber.

That barrel seems to eat all .308 ammo without issue, so I suspect it’s mostly a matter of tolerance stacking in the throat and chamber.

Last edited:

Your chamber is rough but not the issue you have. The gun is WAY out of time. The bolts is ripping the rim off as the case is still under pressure as it is trying to extract. Get a adjustable gas block and screw it all the way in so no gas gets to the bolt. Then start by turning it out a 1/2 turn at a time till you get extraction. Then a 1/4 turn after that should be good.

Likely overgassed as said above (super common in 308 ARs), but you'll want to fix that rough chamber first. There are a couple ways to do that; easiest is a ball hone for the 308 chamber that a gunsmith should have, but you can buy yourself for $40-$50. Keep it wet with a solvent or light oil; laquer thinner, mineral spirits, even WD40 all work fine, and spin it in a cordless drill while moving slightly in and out along the chamber. If it leaves a cross-hatch pattern you did it right. I like to come back with extra fine #0000 steel wool wrapped tightly around a brush for a tight fit in the chamber, again wet with WD40 or similar, to burnish the honed finish. That'll leave a smooth chamber finish that extracts easily and does not mark brass.

Once that's done, definitely tune the gas system. Keep in mind that commercial 308 is generally hotter than mil 7.62, but if you tune it to just work reliably with 7.62 it should be able to put up with being a little overgassed for most 308 loads. Some like Hornady Superformance do better with the gas tuned just for those loads though.

Once that's done, definitely tune the gas system. Keep in mind that commercial 308 is generally hotter than mil 7.62, but if you tune it to just work reliably with 7.62 it should be able to put up with being a little overgassed for most 308 loads. Some like Hornady Superformance do better with the gas tuned just for those loads though.

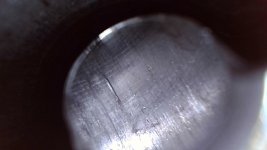

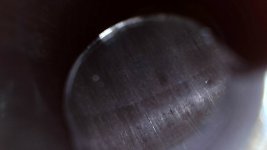

Thanks to everybody who gave me solutions, I have not tried polishing the chamber yet but I took a bore scope to the chamber and took some pictures. Here is what they look like. What could have caused this issue? Manufacturer’s problem? I did have the gun cerakoted. Will polishing the chamber fix these issues?

Attachments

-

46ed6ab5ee1548745516352378a74524.jpeg98.3 KB · Views: 158

46ed6ab5ee1548745516352378a74524.jpeg98.3 KB · Views: 158 -

32d9cf38d70736fe8b55287ff470aac7.jpeg114.4 KB · Views: 155

32d9cf38d70736fe8b55287ff470aac7.jpeg114.4 KB · Views: 155 -

c0c5df4030006094d914c9f896d079e9.jpeg91.4 KB · Views: 157

c0c5df4030006094d914c9f896d079e9.jpeg91.4 KB · Views: 157 -

f8a7710cf81132b4db6a5490809245a1.jpeg89.2 KB · Views: 148

f8a7710cf81132b4db6a5490809245a1.jpeg89.2 KB · Views: 148 -

fd16eac0b97f6f7cdd790c078a7a2d8d.jpeg95.3 KB · Views: 150

fd16eac0b97f6f7cdd790c078a7a2d8d.jpeg95.3 KB · Views: 150 -

fd2ff110250ee3371394940b059d4b69.jpeg102.5 KB · Views: 150

fd2ff110250ee3371394940b059d4b69.jpeg102.5 KB · Views: 150

that does not look safe to fireThanks to everybody who gave me solutions, I have not tried polishing the chamber yet but I took a bore scope to the chamber and took some pictures. Here is what they look like. What could have caused this issue? Manufacturer’s problem? I did have the gun cerakoted. Will polishing the chamber fix these issues?

nothing in those pics is the problem you re having. All i see is scratches with carbon in them.

Pull out the BCG and drop a round into the chamber by hand. Does it drop in freely or stick? I'm wondering if the chamber was cut undersize.

Other possibility, as already mentioned, is the timing. It's trying to unlock the bolt too quickly during the firing cycle. I couldn't find specs on Nefarious' website, so just guessing your barrel is 20" with rifle length gas? What buffer? Standard weight BCG? Adjustable gas block?

If the chamber checks out, I'd start by turning down the gas and going up on BCG or buffer weight to slow the cycle down. I had to use a SA gas block, H3 buffer, and an increased-strength spring on my AR-10 build to get it to stop pulling case rims.

Other possibility, as already mentioned, is the timing. It's trying to unlock the bolt too quickly during the firing cycle. I couldn't find specs on Nefarious' website, so just guessing your barrel is 20" with rifle length gas? What buffer? Standard weight BCG? Adjustable gas block?

If the chamber checks out, I'd start by turning down the gas and going up on BCG or buffer weight to slow the cycle down. I had to use a SA gas block, H3 buffer, and an increased-strength spring on my AR-10 build to get it to stop pulling case rims.

Last edited:

???that does not look safe to fire

Not sure what you are seeing....

Check head space

This

Tight chamber and the gun is ripping the stuck rounds out or trying to.

The very first pic shows the cause of the issue, but it's not the darker longitudinal scratches you're probably looking at, it's the circumferential rings in the chamber (most visible near the upper left of that pic) that were caused by a rough chambering job and not honed out. You can see evidence of this on the brass in the pics in your original post as well, that's why I said it's a rough chamber; I've dealt with this exact issue before and it's clear that's a problem here. Based on the appearance of your brass, you will need to address both this and the overgassing issue to make the rifle reliable.Thanks to everybody who gave me solutions, I have not tried polishing the chamber yet but I took a bore scope to the chamber and took some pictures. Here is what they look like. What could have caused this issue? Manufacturer’s problem? I did have the gun cerakoted. Will polishing the chamber fix these issues?

IME this is usually caused by a manufacturer trying to save costs by cutting down on production times (pushing the reamer too fast/hard) and using reamers past the point where they should be resharpened. Not at all uncommon with lower cost barrels.

You need to hone the chamber or have someone do it for you. This is the correct tool, and I offered some tips on using it in my previous post in this thread. (Get the 400 grit 308 or 7.62x51 if the link doesn't take you straight to it.)

www.amazon.com/gp/product/B00DB8D5U0/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&th=1

ALSO - looking back at your first pics of the brass, they're showing similar longitudinal scratches to the chamber; were you shooting this in really sandy conditions by any chance? Or was the ammo sandy/dirty? Honing will fix it, but whatever happened there it did damage the chamber.

There's nothing unsafe to shoot in those pics though. No idea what that one guy thinks he saw but you don't need to worry about that.

Last edited:

If the case is stuck - he will tear the rim up attempting to mortar the case out of the chamber. So it may not be a timing issue.

My SFAR only had issues like this with Igman also.

Any other ammo and it was fine.

How many rounds of steel case ammo would it take to polish that chamber?

My SFAR only had issues like this with Igman also.

Any other ammo and it was fine.

How many rounds of steel case ammo would it take to polish that chamber?

How many rounds of steel case ammo would it take to polish that chamber?

It won't. That chamber was rough to start with and appears to have been damaged with sand or something (maybe corrosion?). It needs to be honed smooth again, and no sense trying other workarounds when the answer is so simple and easy to do, and relatively cheap too.

Did you get this figured out?

I was out this morning shooting a new 308 Upper (Aero Upper, Criterion barrel, Wilson Combat BCG) and had 7/10 of my reloads stick in the chamber.

Those reloads are using LC stamped once fired NATO brass that I sized with a Whidden FL(?) sizing die. On this same range trip I shot 20x Wincheser 7.62x51, 4x Reminton match 185gr, 5x FGMM 185gr, 20x FGMM 168gr, and 20x PMC X-Tac. All of the factory loads ejected just fine, leading me to believe it something about the brass.

Thinking that maybe my sizing die isn't really full length? This is the first time I've used the Whidden, picked it up second hand from a big lot, so can't 100% be sure its full length resizing. However, while resizing my 1500 surplus rounds, there were several that I couldn't get fully into the die because they were so over expanded.

I think next I'll try using an old lee sizing die on a few of my NATO cases and see how they feel going through the press.

I was out this morning shooting a new 308 Upper (Aero Upper, Criterion barrel, Wilson Combat BCG) and had 7/10 of my reloads stick in the chamber.

Those reloads are using LC stamped once fired NATO brass that I sized with a Whidden FL(?) sizing die. On this same range trip I shot 20x Wincheser 7.62x51, 4x Reminton match 185gr, 5x FGMM 185gr, 20x FGMM 168gr, and 20x PMC X-Tac. All of the factory loads ejected just fine, leading me to believe it something about the brass.

Thinking that maybe my sizing die isn't really full length? This is the first time I've used the Whidden, picked it up second hand from a big lot, so can't 100% be sure its full length resizing. However, while resizing my 1500 surplus rounds, there were several that I couldn't get fully into the die because they were so over expanded.

I think next I'll try using an old lee sizing die on a few of my NATO cases and see how they feel going through the press.

https://nsarmory.us/nefarious-arms-m110-profile-barrel/

$650.00!! For Criterion M110 Clone..FYL

I could have got you a Bartlein 4 Groove M110 Clone for $50 more.

$650.00!! For Criterion M110 Clone..FYL

I could have got you a Bartlein 4 Groove M110 Clone for $50 more.

Did you get this figured out?

I was out this morning shooting a new 308 Upper (Aero Upper, Criterion barrel, Wilson Combat BCG) and had 7/10 of my reloads stick in the chamber.

Those reloads are using LC stamped once fired NATO brass that I sized with a Whidden FL(?) sizing die. On this same range trip I shot 20x Wincheser 7.62x51, 4x Reminton match 185gr, 5x FGMM 185gr, 20x FGMM 168gr, and 20x PMC X-Tac. All of the factory loads ejected just fine, leading me to believe it something about the brass.

Thinking that maybe my sizing die isn't really full length? This is the first time I've used the Whidden, picked it up second hand from a big lot, so can't 100% be sure its full length resizing. However, while resizing my 1500 surplus rounds, there were several that I couldn't get fully into the die because they were so over expanded.

I think next I'll try using an old lee sizing die on a few of my NATO cases and see how they feel going through the press.

If factory stuff runs fine but your reloads don't then obviously a sizing issue, I use a small base sizing die to get around that & trim to 2.00. Just figure that after 3-4 loadings toss em.

Fair point. Could it be I should to run cases back through the die, bumping the shoulders back a few thousands more?If factory stuff runs fine but your reloads don't then obviously a sizing issue, I use a small base sizing die to get around that & trim to 2.00. Just figure that after 3-4 loadings toss em.

Fair point. Could it be I should to run cases back through the die, bumping the shoulders back a few thousands more?

Get a hornady comparator gauge and put it on your calipers... actually measure what you are doing.

Lock-N-Load® Headspace Comparator & Anvil Base Kit - Hornady Manufacturing, Inc

Lock-N-Load® Headspace Comparator & Anvil Base Kit Lock-N-Load® Headspace Comparator The Lock-N-Load® Headspace Comparator extends brass life, improves accuracy, and enhances safety. The gauge measures...

If your reloads are sticking your sizing die isnt set properly... and screwed down until it touches the shell plate isnt "adjusted properly"...

I have had sizing dies I needed to lightly sand the base a little at a time because it was a touch to long to actually get me where I needed to be with my gun...

I had a similar issue with a tight chamber and brass that had been through a few firings. You need a good full length die to make sure the entire case is sized properly. Short Action Customs makes a good unit. Also, you will want a case gauge checker to make sure the resized cases will fit your chamber. JP makes a good one. https://jprifles.com/buy.php?item=JPCG-308

Have this - started at "shell plate touching" and then bumped them back another .006 from there - was amazed at the consistency of the Whidden die. These are just bulk cases from Capitol Armory and for practice.Get a hornady comparator gauge and put it on your calipers... actually measure what you are doing.

Lock-N-Load® Headspace Comparator & Anvil Base Kit - Hornady Manufacturing, Inc

Lock-N-Load® Headspace Comparator & Anvil Base Kit Lock-N-Load® Headspace Comparator The Lock-N-Load® Headspace Comparator extends brass life, improves accuracy, and enhances safety. The gauge measures...www.hornady.com

If your reloads are sticking your sizing die isnt set properly... and screwed down until it touches the shell plate isnt "adjusted properly"...

I have had sizing dies I needed to lightly sand the base a little at a time because it was a touch to long to actually get me where I needed to be with my gun...

I also checked a few on my LE Wilson head space gauge and none of them are long.

Deleted image from quote. Reloads are 0.468" to 0 0.470", same as some new ones.Do you have a Hornady headspace comparator set?

What are your web ODs between factory ammo vs your re-sized cases?

I’m talking about dimension C from this diagram:

I'm also wondering if there is something about this NATO brass that is somehow different Some of the cases were so expanded it was impractical to resize them - see picture attached. I've processed and shot probably 600+ rds of range pickups plus a couple hundred reloaded Alpha brass cases 2-3 times with zero issues like this on my Lilja barreled AR10.

Attachments

Fair point. Could it be I should to run cases back through the die, bumping the shoulders back a few thousands more?

It's worth a try in the past I had rifles that were problematic with regular RCBS dies and a "small base" sizer fixed it.

Those look like they were run through a 240 barrel that should have failed gauging several thousands of rounds ago.Have this - started at "shell plate touching" and then bumped them back another .006 from there - was amazed at the consistency of the Whidden die. These are just bulk cases from Capitol Armory and for practice.

I also checked a few on my LE Wilson head space gauge and none of them are long.

Deleted image from quote. Reloads are 0.468" to 0 0.470", same as some new ones.

I'm also wondering if there is something about this NATO brass that is somehow different Some of the cases were so expanded it was impractical to resize them - see picture attached. I've processed and shot probably 600+ rds of range pickups plus a couple hundred reloaded Alpha brass cases 2-3 times with zero issues like this on my Lilja barreled AR10.

It’s one of my main aversions to buying milsurp brass if you get machine-gun brass that’s stretched to crap.

Just to add data -snip...

Deleted image from quote. Reloads are 0.468" to 0 0.470", same as some new ones.

...snip

SAAMI .308Win commercial cartridge case diameter, measured at the 0.200" reference (up from the base), is 0.4703" (-0.008"). Case diameter at the 1.250" reference is 0.4553" (-0.008").

Small base dies typically form 0.003" smaller diameter than a standard die.

Most people are not setting up their dies correctly. I will say you are not doing it right. Try this. Size a piece of brass but do not lower the ram. Look under the die and between it and the shell holder. If you can see a gap then your press is flexing and you need to turn the die in even more. to get the right amount of sizing. Whenever I hear that your brass is sticking this is usually the issue. You do not need a SB die just set up your dies correct and they will be fine

Have this - started at "shell plate touching" and then bumped them back another .006 from there - was amazed at the consistency of the Whidden die. These are just bulk cases from Capitol Armory and for practice.

I also checked a few on my LE Wilson head space gauge and none of them are long.

Deleted image from quote. Reloads are 0.468" to 0 0.470", same as some new ones.

I'm also wondering if there is something about this NATO brass that is somehow different Some of the cases were so expanded it was impractical to resize them - see picture attached. I've processed and shot probably 600+ rds of range pickups plus a couple hundred reloaded Alpha brass cases 2-3 times with zero issues like this on my Lilja barreled AR10.

You have a perfect example of what some would call a terribly oversized chamber if it happened to be a specific manufacturer(its not oversized).

Your issue is simply your load recipe is too hot and or gas is set too high.

Take the factory load and measure that brass and size your brass to that spec if it shoots well, the sizing issue is not causing the marking on the brass, that is more so due to the premature force of the overgas starting the bolt rearward while the chamber is still under a pressure condition. It's pulling the case out of the chamber allowing it to expland as the base exits the chamber. That expanding toward the base like you are seeing is caused in other instances such as when you add a suppressor to a perfectly gassed gun changing the pressure. The rims being ripped off also confirms that. The specific surface finish in the chamber wouldn't do this, as previously mentioned by tomme boy.

You need to focus on gas adjustment and confirm the buffer is the right weight. Then worry about sizing, but as you mention you are within .002 of target size. You should not need a small base die.

The lilja barrel probably has different specs than this barrel as well, no idea what the bore measures or what the gas port is or what the gas length is compared to this other barrel having issues. I didn't look at nefarious specs but you can compare. Button rifled barrels may calm as they break in, I see speed increase and pressure drop after some rounds.

This line is where the brass becomes unsupported and you can see the pull marks start right there.

The hornady brass has the same pull marks from the chamber but it's not as bad. That's why I think it's related to gas pressure more than anything.

The hornady brass has the same pull marks from the chamber but it's not as bad. That's why I think it's related to gas pressure more than anything.

that pic does not show a unsupported chamber. That is where the WEB of the brass is at. That is where the base and wall of the brass case is at. If it was unsupported it would show a belt like on a mag case. This is part of the problem with an AR platform. They have what is called a coned breech. It is a radius tht is turned on the face of the barrel to help feeding. If it is too deep it can cause an unsupported case head. But that brass in the above pic does not have that.

Thanks for all the replies. This is a long post.

Did some measuring and not sure I'm convinced that my die is setup incorrectly - see comparison chart of new Winchester M80 vs sized vs fired below. Couple of outliers on the processed brass, but the vast majority are at least 0.005" less than the fired cases.

Pic below of shell holder die gap - yields 1.620" on the headspace comparator. This is threading die in til touches shell plate plus 1/8 - 1/4 or so of a turn.

Could be overgassed? I set the gas using the PMC XTAC. With all the extraction issues and my magnetospeed not reading data great I only got a few data points with reloads. Powder TAC, GINEX primers, 147gr pulled ball ammo. These should not be hot loads based on Hodgon data. I'm confident in the powder weights - using FX120i w/ Supertrickler.

Pics of fired cases - reloads that stuck are on the left.

Hoping its more likely overgassed - much rather load up some more sighters/gassers than pull + reprocess what I have loaded and sized.

Did some measuring and not sure I'm convinced that my die is setup incorrectly - see comparison chart of new Winchester M80 vs sized vs fired below. Couple of outliers on the processed brass, but the vast majority are at least 0.005" less than the fired cases.

| Winchester M80 New | LC Processed, Not Loaded | LC Loaded | Fired LC, Stuck | Fired FGMM 168 | Fired PMC X-TAC 147 |

| 1.624 | 1.618 | 1.622 | 1.629 | 1.630 | 1.632 |

| 1.624 | 1.627 | 1.622 | 1.630 | 1.632 | 1.634 |

| 1.624 | 1.621 | 1.623 | 1.630 | 1.629 | 1.632 |

| 1.624 | 1.624 | 1.617 | 1.628 | 1.630 | 1.630 |

| 1.623 | 1.620 | 1.621 | 1.627 | 1.630 | 1.631 |

| 1.623 | 1.625 | 1.614 | 1.628 | 1.628 | 1.632 |

| 1.623 | 1.625 | 1.624 | 1.630 | 1.630 | 1.636 |

| 1.622 | 1.626 | 1.622 | 1.630 | 1.629 | 1.630 |

| 1.622 | 1.622 | 1.621 | 1.629 | 1.628 | 1.634 |

| 1.624 | 1.617 | 1.625 | 1.630 | 1.629 | 1.632 |

| 1.624 | 1.621 | 1.628 | 1.629 | 1.629 | 1.631 |

| 1.622 | 1.621 | 1.622 | 1.629 | 1.629 | 1.631 |

| 1.624 | 1.630 | 1.623 | 1.629 | 1.631 | |

| 1.623 | 1.615 | 1.619 | 1.629 | 1.632 | |

| 1.623 | 1.624 | 1.624 | 1.629 | 1.629 | |

| 1.624 | 1.627 | 1.623 | 1.630 | 1.632 | |

| 1.623 | 1.630 | 1.619 | 1.629 | 1.630 | |

| 1.623 | 1.624 | 1.616 | 1.629 | 1.633 | |

| 1.624 | 1.620 | 1.624 | 1.629 | 1.630 | |

| 1.624 | 1.626 | 1.617 | 1.629 | 1.633 | |

| 1.620 | 1.623 | ||||

| 1.619 | 1.621 | ||||

| 1.627 | 1.618 | ||||

| 1.621 | 1.621 | ||||

| 1.618 | |||||

| 1.621 | |||||

| 1.616 | |||||

| 1.629 | |||||

| 1.616 | |||||

| 1.618 | |||||

| 1.619 |

Could be overgassed? I set the gas using the PMC XTAC. With all the extraction issues and my magnetospeed not reading data great I only got a few data points with reloads. Powder TAC, GINEX primers, 147gr pulled ball ammo. These should not be hot loads based on Hodgon data. I'm confident in the powder weights - using FX120i w/ Supertrickler.

| XTAC, 11 shots | 2721 |

| 43 TAC, 3 shots | 2698 |

| 43.5 TAC, 2 shots | 2728 |

| 44 TAC, 2 shots | 2745 |

| FGMM 168gr, 17 shots | 2504 |

Pics of fired cases - reloads that stuck are on the left.

Hoping its more likely overgassed - much rather load up some more sighters/gassers than pull + reprocess what I have loaded and sized.

if the brass is not sized enough, that pic of your shell holder and die is what I am talking about. You have too much flex in your press. There is a gap between the two.

Also it looks like you have a pressure/ignition issue on some of the cases on the left. But it is a low pressure and carbon is getting in around the case. THAT also can cause extraction issues on rounds fired after all that carbon is deposited into the chamber. It happens with brass as well as steel cases and the carbon build up in the chamber is the reason for sticking. Which leads to WHY???? My guess is weak ignition with the ball powder. Or the brass needs annealed to make it soft to seal the chamber.

Also it looks like you have a pressure/ignition issue on some of the cases on the left. But it is a low pressure and carbon is getting in around the case. THAT also can cause extraction issues on rounds fired after all that carbon is deposited into the chamber. It happens with brass as well as steel cases and the carbon build up in the chamber is the reason for sticking. Which leads to WHY???? My guess is weak ignition with the ball powder. Or the brass needs annealed to make it soft to seal the chamber.

that pic does not show a unsupported chamber. That is where the WEB of the brass is at. That is where the base and wall of the brass case is at. If it was unsupported it would show a belt like on a mag case. This is part of the problem with an AR platform. They have what is called a coned breech. It is a radius tht is turned on the face of the barrel to help feeding. If it is too deep it can cause an unsupported case head. But that brass in the above pic does not have that.

It's unsupported once the brass been pulled prematurely due to the overgas/over pressure. The length varies from the hornady factory to the hand loads showing that it's a pressure factor. I'm not saying the chamber is cut unsupported.

The directional marks....in the brass...show that it's being pulled out under pressure.

Once the pressure is under control either from gas adjustment or buffer weight changes the marks on the brass won't look the same.

Could be overgassed? I set the gas using the PMC XTAC. With all the extraction issues and my magnetospeed not reading data great I only got a few data points with reloads. Powder TAC, GINEX primers, 147gr pulled ball ammo. These should not be

View attachment 8478610

Pics of fired cases - reloads that stuck are on the left.

View attachment 8478611

Hoping its more likely overgassed - much rather load up some more sighters/gassers than pull + reprocess what I have loaded and sized.

Good pic. The right shows slight carbon down the brass, which to me indicates premature movement of the bcg. Could be gas or buffer weight or both.

Left same thing but even more so.

Center rounds looked the best.

With the velocity you posted those seem okay, so until you adjust gas I would hold on any other assumptions. Also based on gas system length, gas adjustment, spring, and buffer weight, the solution could also be less or more spring or less or more buffer depending on how you like to tune your stuff.

Last edited:

No.It's unsupported once the brass been pulled prematurely due to the overgas/over pressure. The length varies from the hornady factory to the hand loads showing that it's a pressure factor. I'm not saying the chamber is cut unsupported.

The directional marks....in the brass...show that it's being pulled out under pressure.

Once the pressure is under control either from gas adjustment or buffer weight changes the marks on the brass won't look the same.

If the rifle were that badly overgassed, with a chamber that rough, you'd have the extractor pulling rims off until it broke. Your assumptions of what's happening here are incorrect. The case is NOT being pulled out under high pressure to be considered "unsupported"; nothing like that is happeing here and if it were, it'd look a lot different than the pics show.

txsailor, first, you have a rough chamber, period. That needs to be fixed.

Second, brass doesn't stick in the chamber because of a gassing issue. It sticks because your sizing is super inconsistent and some cases are too big, and/or the chamber is too rough. You also need to learn to use the comparator correctly to compare to fired brass from that same chamber, not to factory ammo.

You have two obvious issues to fix here:

1 - The chamber is too rough. Have a good gunsmith hone the roughness out of it. This will completely fix one of your two problems.

2 - Your sizing is inconsistent. Two primary solutions to that are to start annealing your brass (this is the main cause - overworked brass gets springy and won't size down as much) and maybe use a better sizing lube as well.

If you do those two things, and set the die to bump shoulders back .003"-.004" compared to fired/deprimed brass from that chamber, you'll eliminate the issues you've described here. It really is that simple.

A small base die should not be needed, and I've rarely seen a situation where a SB die "fixed" a sticking chamber issue where the owner understood how to correctly use a comparator to set up their FL die. If they had, in most cases the SB die wouldn't have been needed.

It looks exactly like like what's happening. If the rifle wasn't over gassed the rims would be intact, the only thing doing that to brass is gas pressure. That's a pic from the OP.No.

If the rifle were that badly overgassed, with a chamber that rough, you'd have the extractor pulling rims off until it broke. Your assumptions of what's happening here are incorrect. The case is NOT being pulled out under high pressure to be considered "unsupported"; nothing like that is happeing here and if it were, it'd look a lot different than the pics show.

txsailor, first, you have a rough chamber, period. That needs to be fixed.

Second, brass doesn't stick in the chamber because of a gassing issue. It sticks because your sizing is super inconsistent and some cases are too big, and/or the chamber is too rough. You also need to learn to use the comparator correctly to compare to fired brass from that same chamber, not to factory ammo.

You have two obvious issues to fix here:

1 - The chamber is too rough. Have a good gunsmith hone the roughness out of it. This will completely fix one of your two problems.

2 - Your sizing is inconsistent. Two primary solutions to that are to start annealing your brass (this is the main cause - overworked brass gets springy and won't size down as much) and maybe use a better sizing lube as well.

If you do those two things, and set the die to bump shoulders back .003"-.004" compared to fired/deprimed brass from that chamber, you'll eliminate the issues you've described here. It really is that simple.

A small base die should not be needed, and I've rarely seen a situation where a SB die "fixed" a sticking chamber issue where the owner understood how to correctly use a comparator to set up their FL die. If they had, in most cases the SB die wouldn't have been needed.

The marks on the brass aren't from the "rough" chamber they are pull marks in the very obvious direction inline with extraction.

Sure he can polish the chamber some but that is not the primary cause, and after that is "fixed" OP will continue to have timing issues caused by over gas.

Lastly, I can create this issue in several AR10s by increasing the gas pressure and flow to a point the that system can barely handle it(several ways), and begins to rip rims off, and deform the lower base area to the point the brass is hard to size, and makes the same pull marks on the brass that the OP provided images of.

If the case is pulled out early and under pressure because of over gas; the point it's pulled, the brass almost immediately gains clearance from the wall of the chamber, and while under pressure that allows abnormal expansion of the brass. It's pretty simple.

Overgassed, yes, as I said earlier. Overgassed to the point of extracting while still under high pressure to bulge cases - no, these rifles won't do that. They rip the rims off first. And the cases shown in those pics aren't bulged there anyway.It looks exactly like like what's happening. If the rifle wasn't over gassed the rims would be intact, the only thing doing that to brass is gas pressure. That's a pic from the OP.

View attachment 8506622

The marks on the brass aren't from the "rough" chamber they are pull marks in the very obvious direction inline with extraction.

Sure he can polish the chamber some but that is not the primary cause, and after that is "fixed" OP will continue to have timing issues caused by over gas.

Lastly, I can create this issue in several AR10s by increasing the gas pressure and flow to a point the that system can barely handle it(several ways), and begins to rip rims off, and deform the lower base area to the point the brass is hard to size, and makes the same pull marks on the brass that the OP provided images of.

If the case is pulled out early and under pressure because of over gas; the point it's pulled, the brass almost immediately gains clearance from the wall of the chamber, and while under pressure that allows abnormal expansion of the brass. It's pretty simple.

You're pointing to a particular spot on the cases and saying they're extracted that far and unsupported at high pressure, but you're just guessing without sound reasoning and experience to back it up. That point you indicated on the cases is where the case web stops, that's why it looks different; it has nothing to do with your theory of extracting cases to that point. If it were actually extracting under high pressure as you're claiming, the case web area would be bulged a LOT. You need to see some actual bulged cases to see the difference; it's not even remotely like what's been shown in this thread.

Beyond that, even being overgassed that rifle still is leaving signs of a rough chamber on the brass. If your rifles make brass look like that, then they have crappy rough chambers too. Hone the chambers out, and even overgassed they won't leave marks like that. No guessing here, speaking from first hand experience.

Always better to say nothing than to open your mouth and remove all doubt.Overgassed, yes, as I said earlier. Overgassed to the point of extracting while still under high pressure to bulge cases - no, these rifles won't do that. They rip the rims off first. And the cases shown in those pics aren't bulged there anyway.

You're pointing to a particular spot on the cases and saying they're extracted that far and unsupported at high pressure, but you're just guessing without sound reasoning and experience to back it up. That point you indicated on the cases is where the case web stops, that's why it looks different; it has nothing to do with your theory of extracting cases to that point. If it were actually extracting under high pressure as you're claiming, the case web area would be bulged a LOT. You need to see some actual bulged cases to see the difference; it's not even remotely like what's been shown in this thread.

Beyond that, even being overgassed that rifle still is leaving signs of a rough chamber on the brass. If your rifles make brass look like that, then they have crappy rough chambers too. Hone the chambers out, and even overgassed they won't leave marks like that. No guessing here, speaking from first hand experience.

I'm not pointing to just any one spot on the case, I am observing the big picture in totality.

Why is that very distinct line at the base?

Why are the lines from the "rough chamber" directional from the top to the bottom of the brass?

When chambers are cut, are they cut radially or some other direction?

How do you know my experience?

Can the case web area bulge a lot or just the amount it's allowed to by the wall of the chamber based on the position it's in during the event of premature extraction?

Is this gun one particular example?

Can this gun be on the edge of this described issue or is the result definite like you say?

Is the rough chamber the main cause of these issues the op is having?

If the pressure went up or down in this example rifle what would be the results in your opinion, please explain both?

Similar threads

- Replies

- 11

- Views

- 430

- Replies

- 33

- Views

- 772