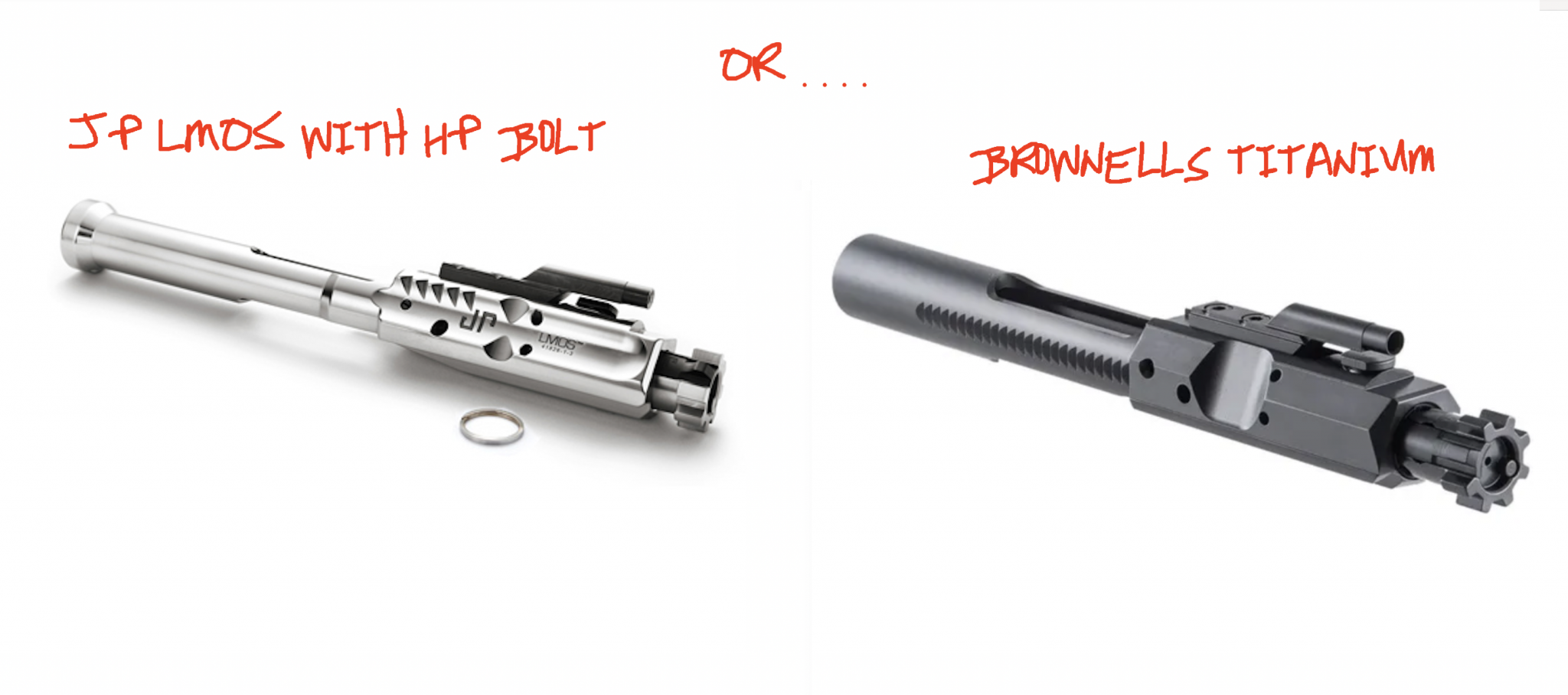

I've got a new 6.5 CM upper on the way and I'm trying to save some weight and a little kick with a low mass BCG. I'm cross shopping the Brownells Titanium BCG and the JP LMOS with the high pressure bolt.

Brownells' 308 BCG looks like a ToolCraft product and in the DLC finish, which I've is super slick and is only 12 oz and I can probably get it for about $260 shipped.

The JP LMOS is pricier, a tad heavier (14.5 oz) but also comes with a high pressure bold that the creed might like better. I perceive the JP to be of higher quality and durability. Street prices are $450 - $480.

My concern is if I go the cheaper Brownells route to save some money and a little weight....... that I'll end up needing to put a high pressure bolt in it down the road ...... in which case......I'd prob just get the JP Rifles LMOS with the HP bolt for $450+ bucks.

Any thoughts on how they compare? Anyone used both?

Brownells' 308 BCG looks like a ToolCraft product and in the DLC finish, which I've is super slick and is only 12 oz and I can probably get it for about $260 shipped.

The JP LMOS is pricier, a tad heavier (14.5 oz) but also comes with a high pressure bold that the creed might like better. I perceive the JP to be of higher quality and durability. Street prices are $450 - $480.

My concern is if I go the cheaper Brownells route to save some money and a little weight....... that I'll end up needing to put a high pressure bolt in it down the road ...... in which case......I'd prob just get the JP Rifles LMOS with the HP bolt for $450+ bucks.

Any thoughts on how they compare? Anyone used both?