(edited: Retitled for subject accuracy)

Time to draw up plans for a winter project.

A few years ago, I wanted to really get into the 6 ARC in a bolt gun but I wasn't fond of the temp sensitive powders (CFE223 and Leverevolution) folks were using to get to 2900+ fps. My goal is to reach 2800+ fps with a 26" barrel, 1:7.5 twist, bolt action using Hornady 105 gr BTHP, Alpha OCD brass, CCI SR magnum primers, and Winchester Staball Match powder.

With the release of Winchester Staball Match in Jan 2023, the new powder got my gears turning again. Staball seems to slot between Varget and CFE223 in the burn rate chart and temp stability tests show reasonable stability for the Staball XX line of ball powers.

Anyone with experience on with similar combination with getting their ARC bolt guns with 105 gr bullets to 2800+ fps?

Any available info for max pressure and expected velocities on QuickLoad?

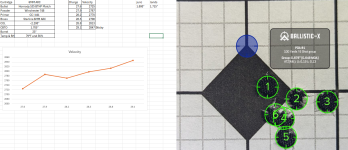

Link to Rob's reloading test with 105 gr BTHP and 28.5 gr Staball Match on a 22" rifle got 2699 fps and SD 16.5.

(Hornady's site doesn't list Staball Match reloading info and Hodgedon's site doesn't have bolt gun info nor the 105gr BTHP listed)

Thank you in advance and happy shooting

Time to draw up plans for a winter project.

A few years ago, I wanted to really get into the 6 ARC in a bolt gun but I wasn't fond of the temp sensitive powders (CFE223 and Leverevolution) folks were using to get to 2900+ fps. My goal is to reach 2800+ fps with a 26" barrel, 1:7.5 twist, bolt action using Hornady 105 gr BTHP, Alpha OCD brass, CCI SR magnum primers, and Winchester Staball Match powder.

With the release of Winchester Staball Match in Jan 2023, the new powder got my gears turning again. Staball seems to slot between Varget and CFE223 in the burn rate chart and temp stability tests show reasonable stability for the Staball XX line of ball powers.

Anyone with experience on with similar combination with getting their ARC bolt guns with 105 gr bullets to 2800+ fps?

Any available info for max pressure and expected velocities on QuickLoad?

Link to Rob's reloading test with 105 gr BTHP and 28.5 gr Staball Match on a 22" rifle got 2699 fps and SD 16.5.

(Hornady's site doesn't list Staball Match reloading info and Hodgedon's site doesn't have bolt gun info nor the 105gr BTHP listed)

Thank you in advance and happy shooting

Last edited: