Hi, i am probably massively overthinking this but, since this is a pretty expensive rig, i want to set it up in the best way. I mounted the scope following a strict procedure (the crosshair is level to gravity and to the top ring bubble, everything is torqued down to specs). It was a long process and i wish i won't have to do it again.

Using the typical criss cross pattern method i torqued every top ring screw to 25 in/lbs with these hawkins light tactical 30 mm rings.

At the end of the process i was very satisfied because the system crosshair-bubble is perfectly leveled to gravity. I noticed that the gap between the front and rear rings is not perfectly even. I read somewhere that someone is even using feeler gauges to check fo uniformity in the gaps. Since of course having the exact identical gap is impossible, i want to understand if in my case the gap differences are acceptable or not.

I measured with a feeler gauge: rear left 0.9 mm (0.035 inches) gap, rear right 0.9 mm gap, front left 0.80 mm (0.031 inches) gap, front right 0.85 mm gap. So basically there is a max 0.1 mm (1/256 inches) difference between the rear and the front rings, while there is a max 0.05 mm (1/512 inches) difference between left and right.

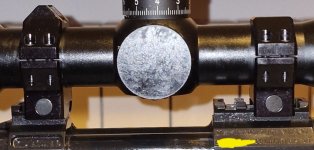

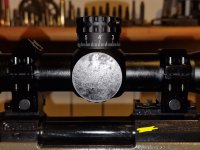

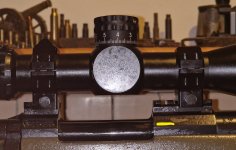

i will post some pics. The gap is not easily visible in these pics i think but when looking in person i notice it.

what do you guys think?

Using the typical criss cross pattern method i torqued every top ring screw to 25 in/lbs with these hawkins light tactical 30 mm rings.

At the end of the process i was very satisfied because the system crosshair-bubble is perfectly leveled to gravity. I noticed that the gap between the front and rear rings is not perfectly even. I read somewhere that someone is even using feeler gauges to check fo uniformity in the gaps. Since of course having the exact identical gap is impossible, i want to understand if in my case the gap differences are acceptable or not.

I measured with a feeler gauge: rear left 0.9 mm (0.035 inches) gap, rear right 0.9 mm gap, front left 0.80 mm (0.031 inches) gap, front right 0.85 mm gap. So basically there is a max 0.1 mm (1/256 inches) difference between the rear and the front rings, while there is a max 0.05 mm (1/512 inches) difference between left and right.

i will post some pics. The gap is not easily visible in these pics i think but when looking in person i notice it.

what do you guys think?