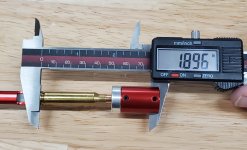

I bought a new 223 Cal rifle and I am using my Hornady Bullet Comparator. As experienced before with other rifles, I am getting different readings repeating the same process.

Attached are the readings and a picture of the comparator with a bullet in it. I am inserting the comparator cartridge into the chamber, making sure the shell seats all the way. After I verify that with a flashlight, I move the bullet gently forward until it stops at the leads. After that I use a cleaning rod that is inserted in the barrel to move the bullet slightly back from the leads and then push the bullet forward against the leads to get the final reading.

All this is done with minimal force to avoid pushing the bullet past the beginning of the leads.

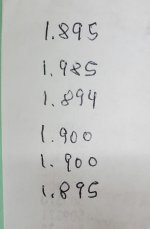

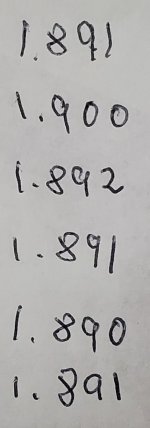

The starting point for the freebore is usually two thousands off the leads, but my readings from the bullet comparator vary by as much as sixteen thousands, making the whole process worthless.

Does anybody have any suggestions as to what I need to do differently in order to get a more acceptable outcome?

Attached are the readings and a picture of the comparator with a bullet in it. I am inserting the comparator cartridge into the chamber, making sure the shell seats all the way. After I verify that with a flashlight, I move the bullet gently forward until it stops at the leads. After that I use a cleaning rod that is inserted in the barrel to move the bullet slightly back from the leads and then push the bullet forward against the leads to get the final reading.

All this is done with minimal force to avoid pushing the bullet past the beginning of the leads.

The starting point for the freebore is usually two thousands off the leads, but my readings from the bullet comparator vary by as much as sixteen thousands, making the whole process worthless.

Does anybody have any suggestions as to what I need to do differently in order to get a more acceptable outcome?