Here's what I've been doing for yrs.

Barrel work or cleaning without the action,..definitely.

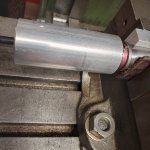

The barrel is held in a aluminum vee cut soft jaw cut on the Bridgeport mill and backed with old thick leather belting to take up taper in the barrel.

Leather belt works wonders on many set ups on a mill where flat and square are not available on the finished project.

No barrel gets installed without borescope and lapping or polishing.

I use aluminum, and this is exactly the barrel thread you want 1.0625" X16 fits the Remington 700 in this case.

Also have tight fitting aluminum fixtures for AR 10s and AR 15, these have a long area for the cleaning rod at rod diameter so one can hammer on it with no flex. For serious lapping AR barrels of moderate, and even good quality may need attention in the gas port area.

The barrel is scoped, before and after to check progress, then installed when satisfied...no barrel break in is done or needed.

Old school wives tales from Precision Shooting days, that I used to follow, are not needed if you prep the barrel before you install it... at least IMO.

A picture is worth a thousand words, so I'll let that entertain ya all.

Use any if it ya want, discard the rest.