A friend/colleague once said, "You can't really ruin it. You just make more work for yourself."

Today that was put to the test. A phone call a week or two ago came in where one of our dealer accounts had run into an issue. He'd sent a job to another shop for a bolt release install on an M700. It didn't go well for that guy. Near as I can tell he either broke the drill or it wandered off location and made a mess. The "fix" was to slather up the goof with JB Weld and try again. While it worked, the owner just couldn't live with it.

So, we get the call.

Here is how we received it. Now, to the uneducated, this looks like a shit sammich. In reality, whoever did it handed me a big favor as the epoxy had already been gutted out and the channel makes for simple work with a TIG welder.

So, that's where we start. Lay some hate with the TIG torch. The filler is a little more "blue" than I'd of liked, but it filled in well with no voids or cancer.

Next is the handwork. I began with a double-cut bastard file, then moved to a single-cut mill file. Last was a few "swipes" across a square wheel grinder to blend.

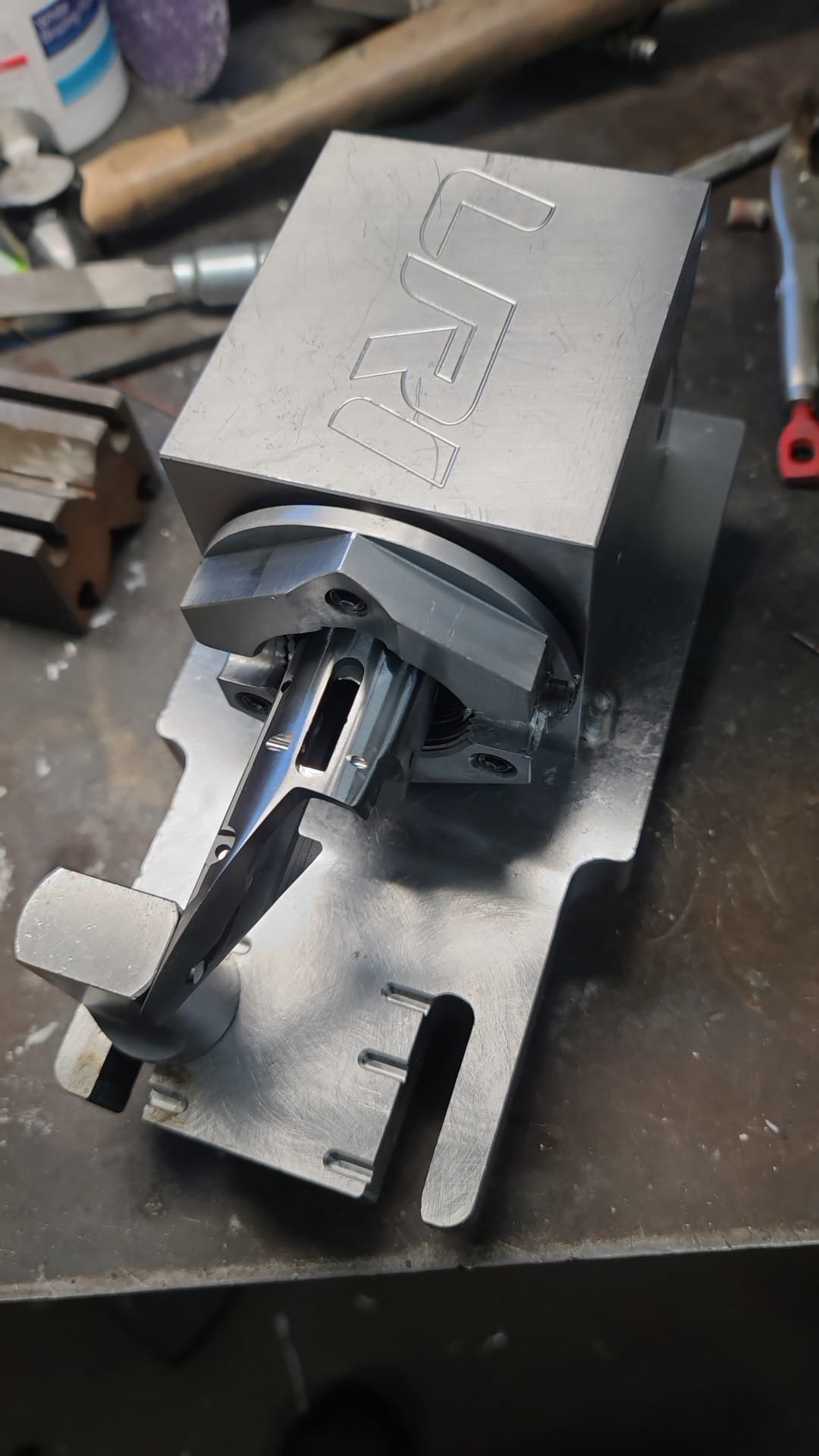

Now we load the part in our fixture and run it through the paces on the 5 axis. We had to get a little creative with the probing just because the program is written with the assumption that a virgin part is being loaded. Not a big deal to navigate around, but one has to be careful. There is a great deal of macro variable work taking place during the setup portion of these programs. "Fat Fingering" offsets is something I desperately try to avoid as it rarely goes well.

Fortunately this time it worked. We were able to recreate the register for the pinhole and drill it without issue. What I did fail to consider though is the position of the bolt stop in relation to the rear flat portion of the rear bridge. Our programs are written/vetted/archived so that they can be retrieved and run in a fully automated format. The shop that originally did the work positioned the stop slightly behind where we do it. I failed to catch that little detail and it resulted in us machining a little further forward than I'd of liked. As a result the bolt stop had a big/fat gap in front of it. That's just not going to work. Back to the welding table...

When designing/making my work holding for blueprinting/bolt release installs I wanted to ensure the ability to remove/replace the fixturing with near-perfect repeatability. The lugged systems now being offered by tooling companies makes this a snap. It allows a person to remove/reinstall a fixture/vise, whatever with a great deal of confidence. Rather than remove the receiver body from the fixture, I just pulled the fixture from the riser block and went to the welding bench. Literally, 2 minutes later I had the front portion filled in and the whole setup was back in the machine. No need to chase down the offsets again. The system just repeats.

Very cool stuff and worth every penny.

The program portion that machines the pocket gets run again and we're done. A few more minutes with the file/sander and it's almost like it never happened. There were a couple of little "nibs" along the edges of the pocket that I felt were better left unmolested as I feared they wouldn't clean up tangent to the outer circumference of our bolt stop. In the grand scheme, I think it's a pretty small inclusion that will be well hidden once the whole assembly is coated.

In closing, It's easy to chastise whoever had a bad day with this job initially. Holding onto a rifle action in a manner that is traceable and repeatable isn't the easiest thing to do. The types of steel typically used for receivers machine beautifully so long as you have a very rigid setup and have good tooling. Overlook any one of these details and the wheels will fall off pretty quickly. It happens. . . My only criticism would be attempting to repair it with JB Weld. McGyver was a TV show meant to entertain. It was never intended as some sort of life quest.

Fortunately, I've attempted to kill my share of actions over the years. Being inherently stubborn lead me down the path of learning how to repair them. I have grown to kinda like jobs like this just because there aren't too many folks that'll even make the attempt.

-Always nice to keep an action out of the trash can.

C.

I forgot to include the vid clip yesterday.

Today that was put to the test. A phone call a week or two ago came in where one of our dealer accounts had run into an issue. He'd sent a job to another shop for a bolt release install on an M700. It didn't go well for that guy. Near as I can tell he either broke the drill or it wandered off location and made a mess. The "fix" was to slather up the goof with JB Weld and try again. While it worked, the owner just couldn't live with it.

So, we get the call.

Here is how we received it. Now, to the uneducated, this looks like a shit sammich. In reality, whoever did it handed me a big favor as the epoxy had already been gutted out and the channel makes for simple work with a TIG welder.

So, that's where we start. Lay some hate with the TIG torch. The filler is a little more "blue" than I'd of liked, but it filled in well with no voids or cancer.

Next is the handwork. I began with a double-cut bastard file, then moved to a single-cut mill file. Last was a few "swipes" across a square wheel grinder to blend.

Now we load the part in our fixture and run it through the paces on the 5 axis. We had to get a little creative with the probing just because the program is written with the assumption that a virgin part is being loaded. Not a big deal to navigate around, but one has to be careful. There is a great deal of macro variable work taking place during the setup portion of these programs. "Fat Fingering" offsets is something I desperately try to avoid as it rarely goes well.

Fortunately this time it worked. We were able to recreate the register for the pinhole and drill it without issue. What I did fail to consider though is the position of the bolt stop in relation to the rear flat portion of the rear bridge. Our programs are written/vetted/archived so that they can be retrieved and run in a fully automated format. The shop that originally did the work positioned the stop slightly behind where we do it. I failed to catch that little detail and it resulted in us machining a little further forward than I'd of liked. As a result the bolt stop had a big/fat gap in front of it. That's just not going to work. Back to the welding table...

When designing/making my work holding for blueprinting/bolt release installs I wanted to ensure the ability to remove/replace the fixturing with near-perfect repeatability. The lugged systems now being offered by tooling companies makes this a snap. It allows a person to remove/reinstall a fixture/vise, whatever with a great deal of confidence. Rather than remove the receiver body from the fixture, I just pulled the fixture from the riser block and went to the welding bench. Literally, 2 minutes later I had the front portion filled in and the whole setup was back in the machine. No need to chase down the offsets again. The system just repeats.

Very cool stuff and worth every penny.

The program portion that machines the pocket gets run again and we're done. A few more minutes with the file/sander and it's almost like it never happened. There were a couple of little "nibs" along the edges of the pocket that I felt were better left unmolested as I feared they wouldn't clean up tangent to the outer circumference of our bolt stop. In the grand scheme, I think it's a pretty small inclusion that will be well hidden once the whole assembly is coated.

In closing, It's easy to chastise whoever had a bad day with this job initially. Holding onto a rifle action in a manner that is traceable and repeatable isn't the easiest thing to do. The types of steel typically used for receivers machine beautifully so long as you have a very rigid setup and have good tooling. Overlook any one of these details and the wheels will fall off pretty quickly. It happens. . . My only criticism would be attempting to repair it with JB Weld. McGyver was a TV show meant to entertain. It was never intended as some sort of life quest.

Fortunately, I've attempted to kill my share of actions over the years. Being inherently stubborn lead me down the path of learning how to repair them. I have grown to kinda like jobs like this just because there aren't too many folks that'll even make the attempt.

-Always nice to keep an action out of the trash can.

C.

I forgot to include the vid clip yesterday.

Last edited: