Hello all,

I've recently dove into reloading and wanted to share my first workup with everyone in the hopes that someone might chime in if anything sounds out of the ordinary. I would hate to find out the hard way that I've created 14 sticks of dynamite. Here goes:

I started by finding my maximum COAL by using a Hornady OAL gauge w/modified case along with their comparator kit. After a few tries recording my results with consistent numbers I then averaged them to 3.307" base to ogive. This measurement is including the comparator which was zeroed in my calipers.

I also took a second to record OAL to get an idea of what I was looking at for an average round length, (base to tip), at max COAL, (base to ogive), and found an average of 2.990". I am planning to run these in my AI 5-rd mags, so worth mentioning the inside of the mag measurement of roughly 2.898" which I rounded down to 2.895" to be safe.

I wasn't too thrilled that I would be jumping so far with my thoughts on starting loads jammed and working backward, but I figured mag length is max, work backwards from there as far as seating depth, shouldn't have an issue. With that being said, I have read a bit about the 168gn Berger liking to be jumped considerably, up to 0.150 if I remember correctly. So there in lies hope.

As such, max COAL became 3.212" from base to ogive, measured in the comparator. This was based roughly on the desired base to tip measurement of 2.895" and results in a jump of ~0.095" to the lands. Interesting maybe to someone; I chose 10 bullets at random and measured them to the tip finding variation not exceeding 0.004". Not to say that my calipers are anything special or that I'm an expert with them, and also not to say that I am loading based on base to tip measurement…as I am seating based on an ogive calculated die.

Moving on, I set up my seating die to 3.210" with a dedicated unprimed case and a brand new shiny bullet. I then recorded the data on the case in Sharpie and placed it neatly away in the die case. I chose this ogive measurement as a nice round version of the above COAL desired. Having done that I moved along to powdering 14 cases in increments of 0.5gn. I weighed each charge carefully.

Referencing Alliant's website, Hornady's manual, and one other reference that seems to have slipped my mind, I arrived at some ideas on where to start. Long story short, I wrote down all the max load numbers from each reference where they used PP2000MR with 165-168gn bullets. I also looked at 155gn and 178gn max loads with the same powder. I came up with an average of 48.85gn which I rounded up to 49gn.

With that number, I subtracted 10% and arrived at 44.1gn which I called 44.0gn in order to salvage my sanity as I am not so premium with the math anyhow. Starting there I wrote down and then loaded up the following ladder:

1-44.0

2-44.5

3-45.0

4-45.5

5-46.0

6-46.5

7-47.0

8-47.5

9-48.0

10-48.5

11-49.0

12-49.5

12 1/2

14-50.5

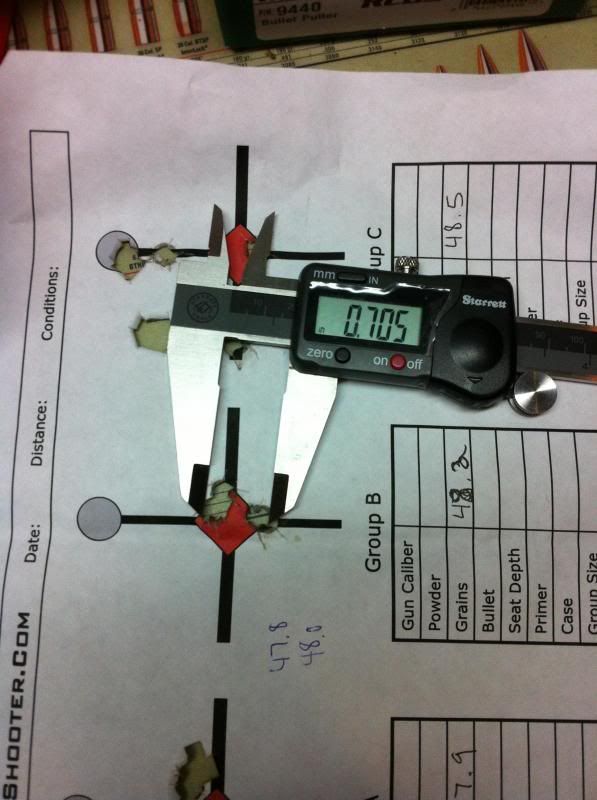

I plan to work it at 300yds soon.

For the Record so I haven't missed anything:

Never Fired Lapua brass, lightly inside chamfered

CCI BR-2 primers

Alliant PP2000MR 44.0-50.5gn

COAL-3.210"

OAL~2.895"

Max Chamber COAL-3.307"

Remington 700 action

20" 1:10 twist

Berger 168gn VLD Target .308

Sorry for the novel and details. I hope I covered everything and conveyed myself appropriately. I'm not too worried exactly… but it would be lovely to know I'm not going to hurt something.

but it would be lovely to know I'm not going to hurt something.

Anyone running anything similar they would like to share or notice anything screwy here that I need to address?

As an added precaution, I followed advice I had read on here somewhere and I recorded the round number and grains on each round with black sharpie. Any rounds past number 8 received a healthy dose of red sharpie to the projectile itself. Just to remind me be extra nervous..

Points of concern or lessons learned greatly appreciated!

I've recently dove into reloading and wanted to share my first workup with everyone in the hopes that someone might chime in if anything sounds out of the ordinary. I would hate to find out the hard way that I've created 14 sticks of dynamite. Here goes:

I started by finding my maximum COAL by using a Hornady OAL gauge w/modified case along with their comparator kit. After a few tries recording my results with consistent numbers I then averaged them to 3.307" base to ogive. This measurement is including the comparator which was zeroed in my calipers.

I also took a second to record OAL to get an idea of what I was looking at for an average round length, (base to tip), at max COAL, (base to ogive), and found an average of 2.990". I am planning to run these in my AI 5-rd mags, so worth mentioning the inside of the mag measurement of roughly 2.898" which I rounded down to 2.895" to be safe.

I wasn't too thrilled that I would be jumping so far with my thoughts on starting loads jammed and working backward, but I figured mag length is max, work backwards from there as far as seating depth, shouldn't have an issue. With that being said, I have read a bit about the 168gn Berger liking to be jumped considerably, up to 0.150 if I remember correctly. So there in lies hope.

As such, max COAL became 3.212" from base to ogive, measured in the comparator. This was based roughly on the desired base to tip measurement of 2.895" and results in a jump of ~0.095" to the lands. Interesting maybe to someone; I chose 10 bullets at random and measured them to the tip finding variation not exceeding 0.004". Not to say that my calipers are anything special or that I'm an expert with them, and also not to say that I am loading based on base to tip measurement…as I am seating based on an ogive calculated die.

Moving on, I set up my seating die to 3.210" with a dedicated unprimed case and a brand new shiny bullet. I then recorded the data on the case in Sharpie and placed it neatly away in the die case. I chose this ogive measurement as a nice round version of the above COAL desired. Having done that I moved along to powdering 14 cases in increments of 0.5gn. I weighed each charge carefully.

Referencing Alliant's website, Hornady's manual, and one other reference that seems to have slipped my mind, I arrived at some ideas on where to start. Long story short, I wrote down all the max load numbers from each reference where they used PP2000MR with 165-168gn bullets. I also looked at 155gn and 178gn max loads with the same powder. I came up with an average of 48.85gn which I rounded up to 49gn.

With that number, I subtracted 10% and arrived at 44.1gn which I called 44.0gn in order to salvage my sanity as I am not so premium with the math anyhow. Starting there I wrote down and then loaded up the following ladder:

1-44.0

2-44.5

3-45.0

4-45.5

5-46.0

6-46.5

7-47.0

8-47.5

9-48.0

10-48.5

11-49.0

12-49.5

12 1/2

14-50.5

I plan to work it at 300yds soon.

For the Record so I haven't missed anything:

Never Fired Lapua brass, lightly inside chamfered

CCI BR-2 primers

Alliant PP2000MR 44.0-50.5gn

COAL-3.210"

OAL~2.895"

Max Chamber COAL-3.307"

Remington 700 action

20" 1:10 twist

Berger 168gn VLD Target .308

Sorry for the novel and details. I hope I covered everything and conveyed myself appropriately. I'm not too worried exactly…

Anyone running anything similar they would like to share or notice anything screwy here that I need to address?

As an added precaution, I followed advice I had read on here somewhere and I recorded the round number and grains on each round with black sharpie. Any rounds past number 8 received a healthy dose of red sharpie to the projectile itself. Just to remind me be extra nervous..

Points of concern or lessons learned greatly appreciated!

Last edited: