Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Printed AR Lowers

- Thread starter lariat

- Start date

i would not buy a 3d printed lower at a gun show.....period.....hell, im hard pressed to buy ANY commercial product that is 3d printed.

im guessing bubba found a 3d model of a lower and printed it on his $200 printer.....it will last maybe a magazine.

when you design in polymer, and especially for 3D prints, you cant just port over an aluminum part and expect it to work.

most 3d prints suffer from Z-layer Anisotropy....essentially they want to delaminate along the layers.

with a properly designed 3d model.....and a proper 3d printer (mark forged ONYX at a minumum) you can create a half decent lower.

that being said, i would much rather just buy a polymer80 lower and have a much better product.

im guessing bubba found a 3d model of a lower and printed it on his $200 printer.....it will last maybe a magazine.

when you design in polymer, and especially for 3D prints, you cant just port over an aluminum part and expect it to work.

most 3d prints suffer from Z-layer Anisotropy....essentially they want to delaminate along the layers.

with a properly designed 3d model.....and a proper 3d printer (mark forged ONYX at a minumum) you can create a half decent lower.

that being said, i would much rather just buy a polymer80 lower and have a much better product.

You're not wrong, but technology is advancing fast. AR lower takes a lot less punishment than this.i would not buy a 3d printed lower at a gun show.....period.....hell, im hard pressed to buy ANY commercial product that is 3d printed.

im guessing bubba found a 3d model of a lower and printed it on his $200 printer.....it will last maybe a magazine.

when you design in polymer, and especially for 3D prints, you cant just port over an aluminum part and expect it to work.

most 3d prints suffer from Z-layer Anisotropy....essentially they want to delaminate along the layers.

with a properly designed 3d model.....and a proper 3d printer (mark forged ONYX at a minumum) you can create a half decent lower.

that being said, i would much rather just buy a polymer80 lower and have a much better product.

Porsche Puts 3D Printed Pistons to the Test

The new technology boosts Porsche's 911 GT2 RS by another 30 horsepower.

Of course that wasn't done on a $200 printer

oh absolutely, metal DMLS is going to be a game changer in manufacturing in the near future....hell, 3D printing in general is going to challenge traditional manufacturing within our lifetimeYou're not wrong, but technology is advancing fast. AR lower takes a lot less punishment than this.

Porsche Puts 3D Printed Pistons to the Test

The new technology boosts Porsche's 911 GT2 RS by another 30 horsepower.www.designnews.com

Of course that wasn't done on a $200 printer

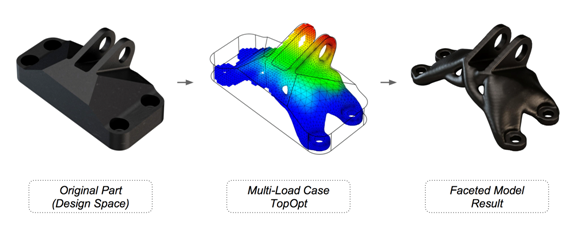

some of the work they are doing with generative design based on FEA results is absolutely next level engineering.

With Generate, a user uploads a STEP file into the software, chooses faces on the CAD model, and inputs the amount of load that the face will be subject to and the preferred weight reduction. Using finite element analysis and the company's voxel-based design algorithm, Generate will remove large, nonvital chunks of a model, leaving an organic shape that still performs the basic function of the original part, but without all of the excess weight.

Topology Optimization for 3D Printing Hits the Cloud with Generate

Frustum CEO Jesse Blankenship explains how his cloud-based software generates new designs for 3D printing.

There's a right and a wrong way to do a lot of things. Bubba at the gun show wouldn't be my first choice. Think of the difference between rattle can paint and a good DLC coating, that's the disparity in quality I'd be expecting to navigate. Both do the same observable things basically, but only one is actually worth doing when it comes to hard use applications.

Cue the butthurt krylon commandos...

Cue the butthurt krylon commandos...

Plastic is not the right material for an AR lower (at least not without modifying the geometry somewhat), and the situation does not get any better with the sort of 3D printing available to hobbyists. Yes, all sort of amazing things are happening in additive manufacturing, but none of that is on display at the average local gunshow.

Gun show? You mean the place they charge you $15 entry to sell you shitty jerky for $5/oz at?

Cletus probably printed it using PLA, the basic media for 3D printing. It's just can be sturdy but not firearm strong. A well designed lower can hold up a few magazines. A lot giving out at the 100-200 range. Can use stronger material like PETG or carbon fiber reinforced media. Those will hold up better. Wonder if the seller has their FFL as a manufacturer.

3d printers can use metals now. It’s only a matter of time until reliable, non-polymer lowers are produced. I know when I have a high enough net worth i’m going to buy one of those toys and see what I can come up with (probably a bunch of overpriced paperweights, but a man can dream!)Anyone have any experience with them? Saw some at a gun show the other day for sale. Was wondering what material they were made of and if they would actually hold up under real stress.

The polymer lowers that are printed, from what I have seen, can last a hundred rounds if you’re lucky. Total gimmick at the moment.

Gun show? You mean the place they charge you $15 entry to sell you shitty jerky for $5/oz at?

Hey, they have stuffed animals too... And $1000 AK's and M4's, which one is worse I don't know.

I can probably cut an 80% for you out of a 2x4 if you like, it'll be stronger and since cheap as fuck seems to be the way you're going, I'll do it all for $190!

Seriously though, I doubt it's there yet and I don't know why anyone would be interested in it beyond novelty.

Now forged carbon fiber, that shit looks interesting.

You might want one of these. You put in 80% lowers, and it completes them. It's like $2100 but if you and a couple of friends want to split the cost it could be worth it. Sharing the cost of this with a couple of friends might not be legal but whatever.

ghostgunner.net

ghostgunner.net

Ghost Gunner

ghostgunner.net

ghostgunner.net

They have stuffed animals at your gun shows?Hey, they have stuffed animals too... And $1000 AK's and M4's, which one is worse I don't know.

I can probably cut an 80% for you out of a 2x4 if you like, it'll be stronger and since cheap as fuck seems to be the way you're going, I'll do it all for $190!

Seriously though, I doubt it's there yet and I don't know why anyone would be interested in it beyond novelty.

Now forged carbon fiber, that shit looks interesting.

Damn. All we get at mine are people with strollers trying to run you over, kids running around unsupervised, and a lot of people who need some further edumacatin' before they become gun owners.

You could also buy it from your buddy and then sell it back when you’re doneYou might want one of these. You put in 80% lowers, and it completes them. It's like $2100 but if you and a couple of friends want to split the cost it could be worth it. Sharing the cost of this with a couple of friends might not be legal but whatever.

Ghost Gunner

ghostgunner.net

I made a few lowers on a gen 1 ghost gunner mill. The safety wasn't always aligned perfectly but they all run great (and are safe.) I've built a AR .22 on a polymer lower with CMMG upper, very lite weight. I use it for my niece and nephew but I'm not sure I would want to run .223 on it...

I’m waiting for the .99 cent 3-D barrel extensions! Let’s quit fuckin a round and really tear up some shit!

PLA is one of the stronger printable materials, stronger than PETG and ABS. The problem with PLA is that it can't handle hardly any heat and it's a fairly brittle plastic. It would break right at the rear pin hole within a magazine because there's just a lot of stress in that joint. Even specifically designed polymer lowers had to use brass or other metals to reinforce that area. The current dimensions for an AR lower just don't lend themselves to pure plastic. It could be done, but it would require a MUCH bulkier lower.

I was introduced to 3D printing by a co-worker in about 2008. He had a ”gear set” that he had printed at home. It looked like he had cooked angel hair pasta, roughly arranged it into the shape of a “gear,” and allowed it to dry. He was beside himself with glee. I was all like “3D printing won’t ever be a thing, but that’s a cool, I guess.” I was wrong. But, I won‘t be buying any gun show 3D printed lowers either...

PLA is one of the stronger printable materials, stronger than PETG and ABS.

Even for us with lame little FDM machines, there is much better stuff than PLA (nylon is a good start).

The current dimensions for an AR lower just don't lend themselves to pure plastic. It could be done, but it would require a MUCH bulkier lower.

This right here is something I've been saying for a while. The part was originally designed to be constructed from forged AL7075. Even a proper injection-molded part, made from a good resin, would need to have different wall section thickness (some of it for strength in the final part, some of it to improve manufacturability).

The correct way to do this is with a ground-up redesign, starting with an understanding of the various forces involved.

This^^^. See the CavArms polymer lower (no longer in production) or the KE Arms lower (in pre-production)...Even for us with lame little FDM machines, there is much better stuff than PLA (nylon is a good start).

This right here is something I've been saying for a while. The part was originally designed to be constructed from forged AL7075. Even a proper injection-molded part, made from a good resin, would need to have different wall section thickness (some of it for strength in the final part, some of it to improve manufacturability).

The correct way to do this is with a ground-up redesign, starting with an understanding of the various forces involved.

Those are injection molded, which lends itself to a whole host of different variables to play with that aren't available in 3D printing at the moment.This^^^. See the CavArms polymer lower (no longer in production) or the KE Arms lower (in pre-production)...

Not printed but the KP15 polymer lowers look promising. https://www.brownells.com/rifle-par...ipped-lower-receivers-polymer-prod132660.aspx

Last edited:

I was introduced to 3D printing by a co-worker in about 2008. He had a ”gear set” that he had printed at home. It looked like he had cooked angel hair pasta, roughly arranged it into the shape of a “gear,” and allowed it to dry. He was beside himself with glee. I was all like “3D printing won’t ever be a thing, but that’s a cool, I guess.” I was wrong. But, I won‘t be buying any gun show 3D printed lowers either...

I have some gears for my Atlas Lathe that are PLA and actually work really well. They're noisy but they've held up. That said the originals were Zamak so yeah they weren't a super strength requirement.

Hey, they have stuffed animals too... And $1000 AK's and M4's, which one is worse I don't know.

I can probably cut an 80% for you out of a 2x4 if you like, it'll be stronger and since cheap as fuck seems to be the way you're going, I'll do it all for $190!

Seriously though, I doubt it's there yet and I don't know why anyone would be interested in it beyond novelty.

Now forged carbon fiber, that shit looks interesting.

On a forum I'm on there's a guy who did a 0% build using wood. Worked out just fine from what I remember. Dead serious.

I'm actually trying to do a 10/22 right now. Iterated a few times trying to get the dimensions where everything works based off the print I have. It's definitely not something where you "print and go" there is a learning curve to 3D printing especially when you're not just making Pikachu figurines because the kid likes em and you have to maintain dimensional tolerances with a receiver.

I've seen a lower that's kind of an ACR knockoff and that seems like the way to go. It's got more of a hunter style stock with the lower built into it that should be way stronger than a bit of plastic surrounding a buffer tube. I will make a bold prediction that AR15s will fall by the side for 3D print builds because the AR180 platform's integral recoil buffer/spring system is much, much more conducive to making a lower that doesn't break. Then again another option may be making what amounts to a cav-arms setup where there's a tube epoxied into the stock. There's also stuff like the FGC9 (Fuck Gun Control) that are designed to be more 3D print compatible. I truly see that (printer optimized) as the future of 3D printed guns. Also, the quality is getting progressively better and at a very fast rate. I think metal will come to the masses in a few years and resin is supposed to be a superior option. Obviously that stuff will be expensive at first but as always the price will come down and the competition/availibility will go up. Then again printing metal is probably a whole new thing in terms of liability.

Last edited:

Even for us with lame little FDM machines, there is much better stuff than PLA (nylon is a good start).

This right here is something I've been saying for a while. The part was originally designed to be constructed from forged AL7075. Even a proper injection-molded part, made from a good resin, would need to have different wall section thickness (some of it for strength in the final part, some of it to improve manufacturability).

The correct way to do this is with a ground-up redesign, starting with an understanding of the various forces involved.

There are files out there now that are a redesign of AR lowers to address just those issues. There is also material currently available on the market (Nylons and filled nylons) that work perfectly fine for an AR lower and will last thousands of rounds. Most cheap printers need modded to run those materials anyway, so alot of people print them out of lesser plastics that will not hold up to the abuse.

I really wanted to post a few of these in the fuel filter thread. *chuckle*

A little late but I have been doing some serious research into the plausibility of use, simply for my on curiosity and after seeing tests of lowers on things like the scorpion evo that have held up. By testing I mean looing at every aspect of printing from material like ABS, PLA, PLA+, Carbon Fiber, Extrustion temperatures, infill design, number of perimeters and % of fill, layer height, extrusion width, extrusion speed, cooling speed, post print baking and a few other aspects as well as taking information from the strength tests from some youtubers like this german engineer doing a lot of the same with a channel called CNC Kitchen. Where he mostly tests load weights for strength I am also looking at impact resistances due to recoil. Pretty much I feel like im starting from scratch on ballistic testing off old Chinese firework math... but its actually pretty promising.

From the numbers it's certainly possible to build longer lasting lowers with current tech and printers in the $350 dollar range if you know what your doing

(cr-10's and similiar). But this would also depend on the firearm design and how much stress and heat is put on them, as im sure you all know, but if they can build the main housing of the scorpion evo with how hard that bolt thumbs the rear and put a few hundred rounds through it just fine then an AR lower is certainly usable. I would not want to use either as a long term duty rifle by any means, but if was that or nothing it would be usable to get a better option if it ever came to that type of situation.

If I had to use a 3d printer at this time for a long term solution though.. honestly it would be as a mold and go straight for casting a lower from a print.... But I am still praying for the day someone creates some good programs to run the Ghost gunner for straight aluminum stock which I heard rumor of a little over a year ago.

From the numbers it's certainly possible to build longer lasting lowers with current tech and printers in the $350 dollar range if you know what your doing

(cr-10's and similiar). But this would also depend on the firearm design and how much stress and heat is put on them, as im sure you all know, but if they can build the main housing of the scorpion evo with how hard that bolt thumbs the rear and put a few hundred rounds through it just fine then an AR lower is certainly usable. I would not want to use either as a long term duty rifle by any means, but if was that or nothing it would be usable to get a better option if it ever came to that type of situation.

If I had to use a 3d printer at this time for a long term solution though.. honestly it would be as a mold and go straight for casting a lower from a print.... But I am still praying for the day someone creates some good programs to run the Ghost gunner for straight aluminum stock which I heard rumor of a little over a year ago.

Hi,

Just FWIW and personal experience utilizing 3D printers for different prototyping projects.

There is not a 3D printer under 600k that can print metal to a degree that it is safe to use.

Even printing some of the polymers and ABS, etc etc are done on machines that are 500k+

Sincerely,

Theis

Just FWIW and personal experience utilizing 3D printers for different prototyping projects.

There is not a 3D printer under 600k that can print metal to a degree that it is safe to use.

Even printing some of the polymers and ABS, etc etc are done on machines that are 500k+

Sincerely,

Theis

There are some continuous carbon fiber filaments that look promising, but it needs to be fully explored. It’s not so much the printer sometimes as it is the material/humidity in the material/ printing temp. If it’s just an item like a lower a high end printer isn’t needed, but the material has to be higher quality.Hi,

Just FWIW and personal experience utilizing 3D printers for different prototyping projects.

There is not a 3D printer under 600k that can print metal to a degree that it is safe to use.

Even printing some of the polymers and ABS, etc etc are done on machines that are 500k+

Sincerely,

Theis

Totally agree. I print all kinds of trinkets with my 3D printer. I would never attempt to print some of the things that people are trying to sell. It’s great for scope throw levers, printing a lower in my opinion would be a waste of time. It’s just asking too much from a 2-500 dollar machine and a filament not intended for the job.Hi,

Just FWIW and personal experience utilizing 3D printers for different prototyping projects.

There is not a 3D printer under 600k that can print metal to a degree that it is safe to use.

Even printing some of the polymers and ABS, etc etc are done on machines that are 500k+

Sincerely,

Theis