Hi Guys

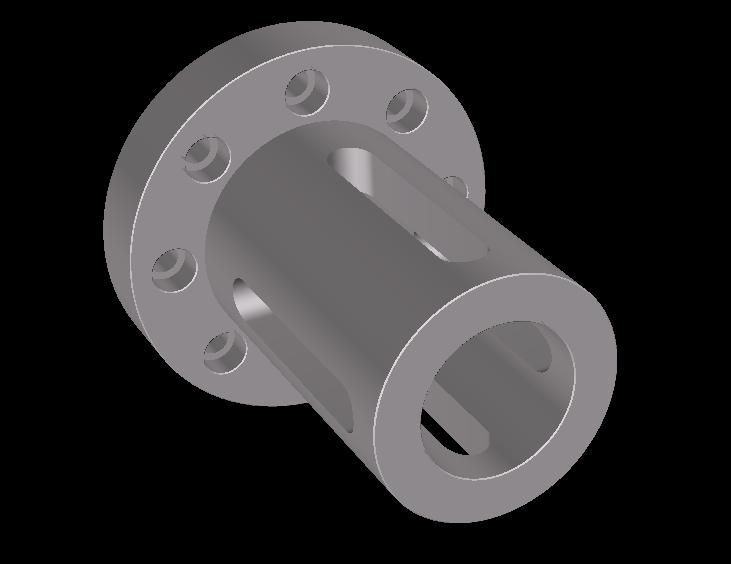

I have been trying (without success) to get a 12" length of 4" X .75" 6061 T6 Tube here in the UK to make a Spider.

I am in AL Saturday 24th thru May 1st and if I can find a piece I will throw it in my checked luggage.

Any help greatly appreciated

I have been trying (without success) to get a 12" length of 4" X .75" 6061 T6 Tube here in the UK to make a Spider.

I am in AL Saturday 24th thru May 1st and if I can find a piece I will throw it in my checked luggage.

Any help greatly appreciated