.308 FDE PredatAR

I've already done a review on my FDE PredatAR in the past so this review will be relatively short.

A lot of the same modifications that have been done on the (OBR Part 1) are the same as the PredatAR so no need to reiterate.

The FDE PredatAR has had multiple barrels and different calibers all very successful.

The original 16" .308 Larue barrel that came with the FDE Ptar was one of the worst I have ever owned, the XTRAXN chamber had extremely aggressive fluting and a oversized chamber that resulted in several issues that ranged from cracked cases just above the case heads, deformed extractor grooves due to case extraction during high chamber pressure, blown/ pierced primers and because of the oversized chamber the brass was rendered absolutely unusable.

I've seen these issues on several .308 Larue barrels but definitely not always consistent from gun to gun some have zero issues with function or resizing brass with 100% reliability.

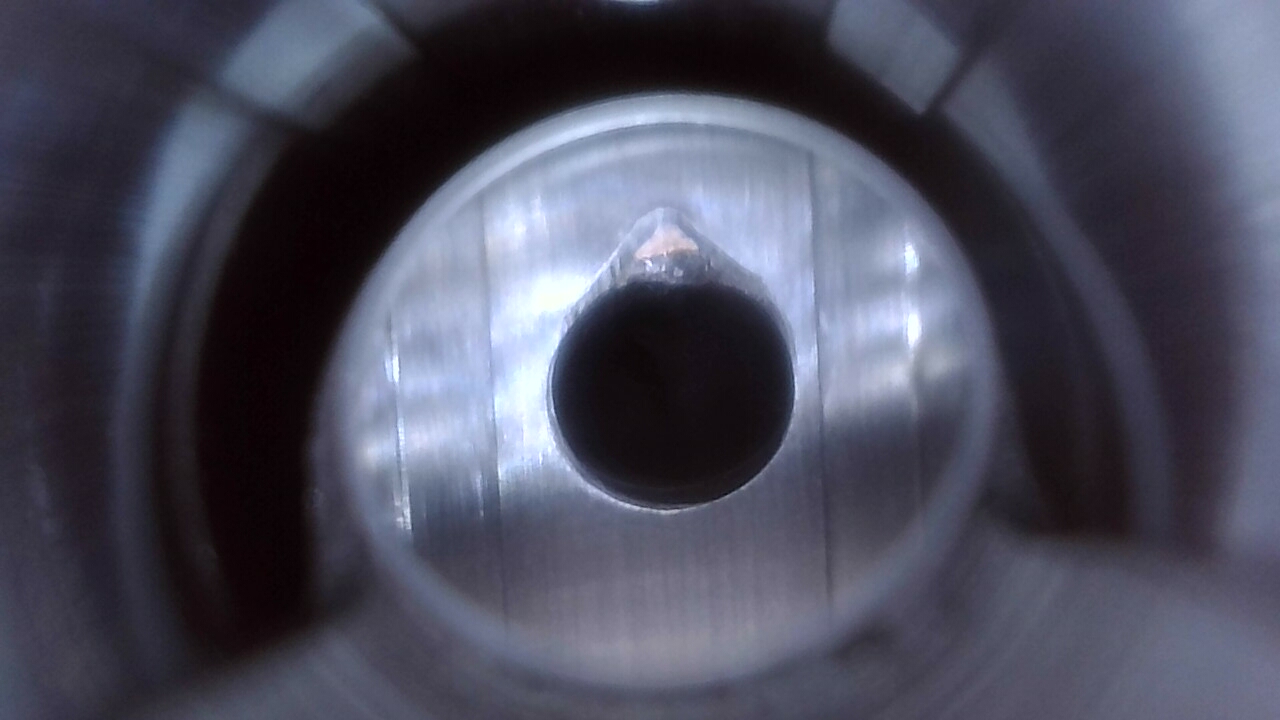

There are multiple variations of the Larue .308 chambering jobs floating around, I've got several Larue barrels in my spare parts/junk bin that I'll post pics of to show the various inconsistent chamber work.

The original .308 Larue 16" Barrel, you could take a metal punch and run it over the chamber flutes and it would sounded like running you finger down a washboard.

The below images is a excellent illustration of what the brass looked like in the original 16" Larue Ptar barrel posted by another Larue owner who suffered from the same issues. (Not my Image)

I exhausted all options trying to make the original Larue Barrel work. I tried multiple brands of Sizing Dies, had Forster make a custom Sizing Die..Annealing the brass after every firing..Imperial Sizing Die Wax, but nothing worked.

The standard .308 Bolt that came with FDE Ptar had a chamferred firing pin hole that produced severe primer flow and pierced primers.

The pictures below shows the difference between the standard Larue .308 Bolt Vs the new HP Bolt and what a difference the new HP bolt makes.

(3 ) .308 Fired FGMM and (3) .308 Hot/High pressure Handloads.

The Small Rifle Primer 6.5CM Lapua Brass shot out of my custom Bartlein barrels come out even cleaner, majority of them are still going strong with 10+ firings

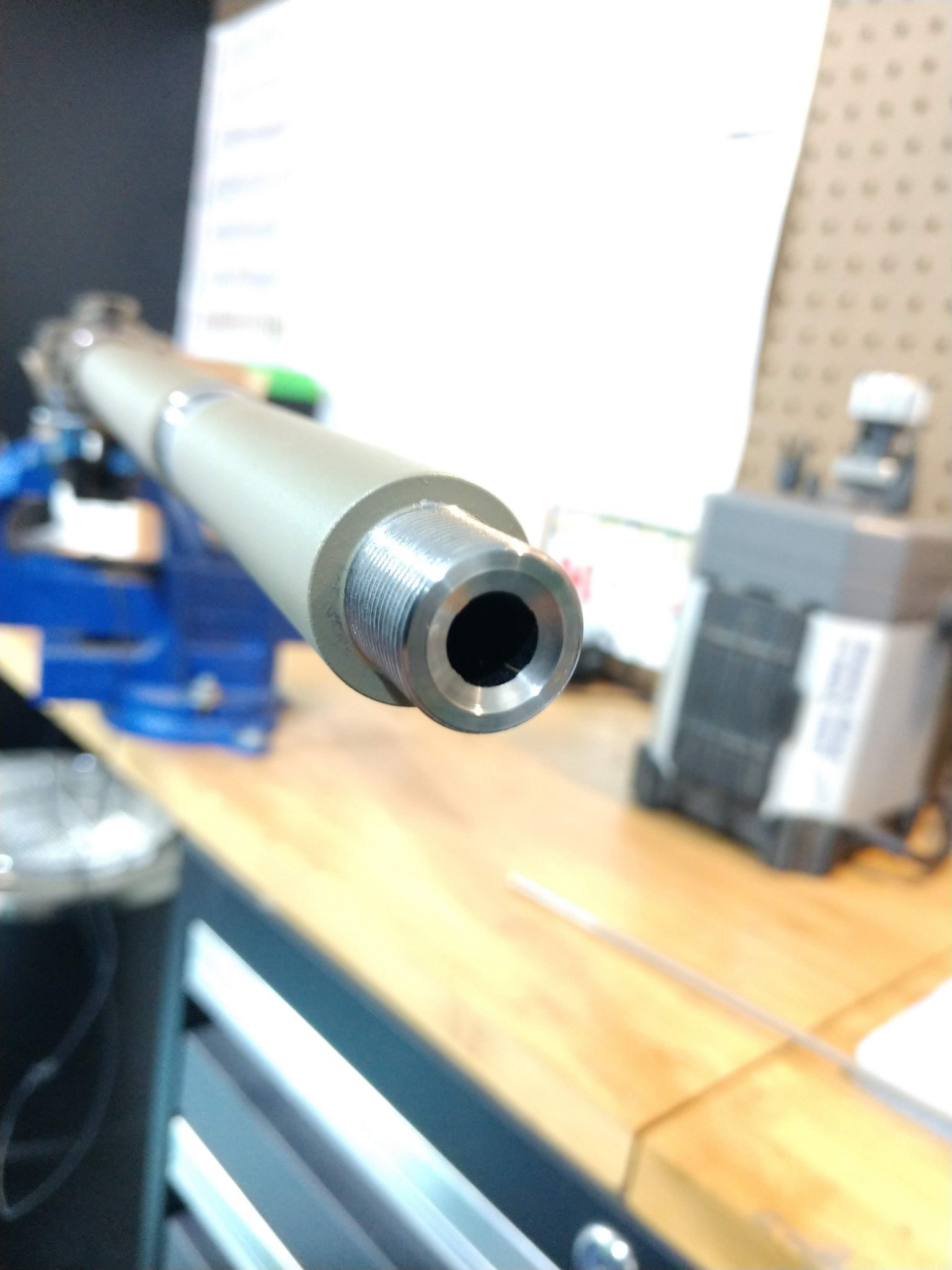

The first barrel I installed was a 18" .308 Bartlein from Paul Ross. 1-10 Twist/ 4 Groove / M110 Contour / RLG/ 5/8x24 Threads/ Oversized Barrel Extension.

The barrel design made the FDE Ptar perfectly balanced and a absolute pleasure to shoot.

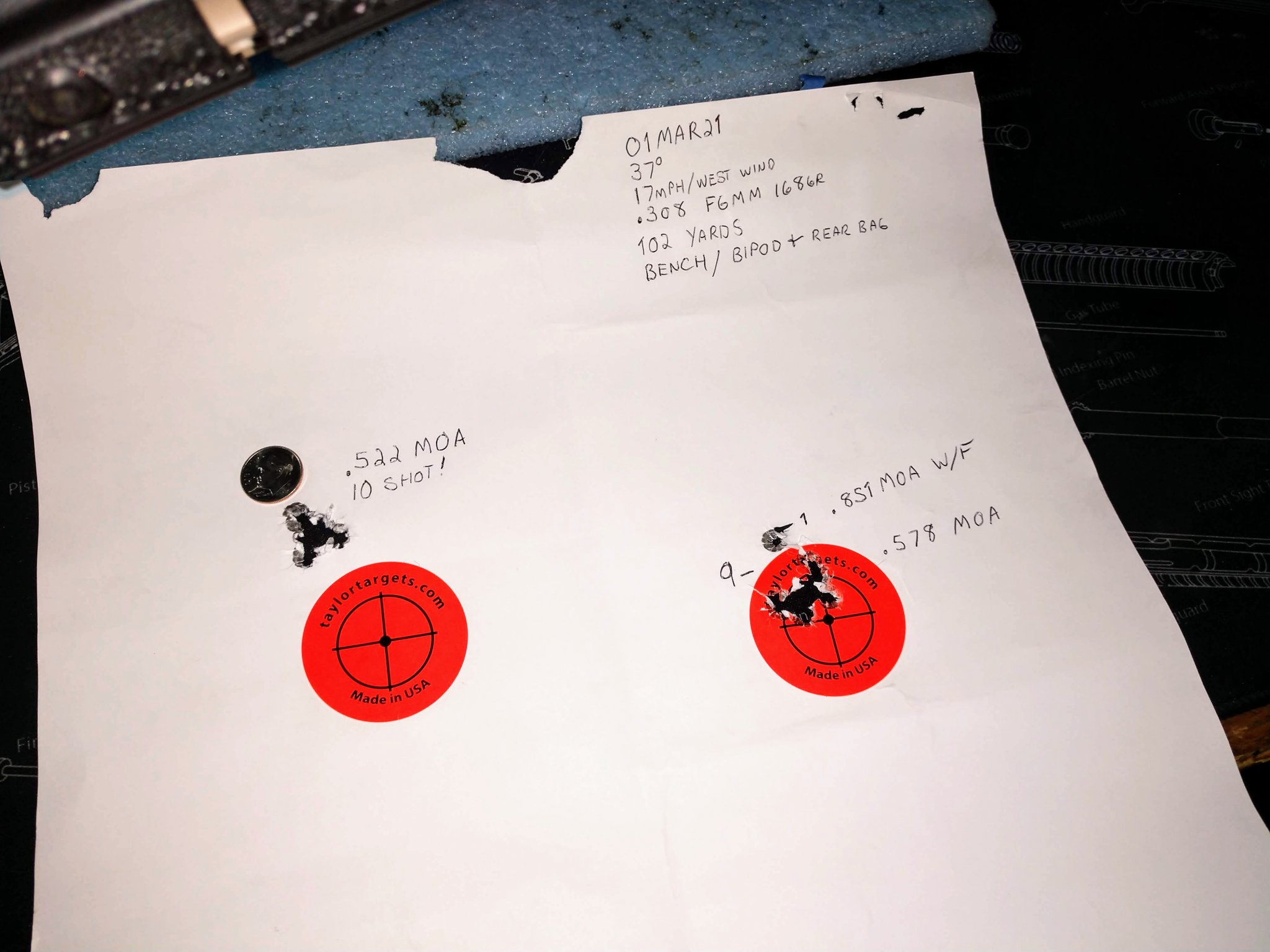

To no surprise the Custom .308 Bartlein that Paul Ross turned was easily a Sub 1/2" MOA barrel with a variety of Handloads and factory ammo.

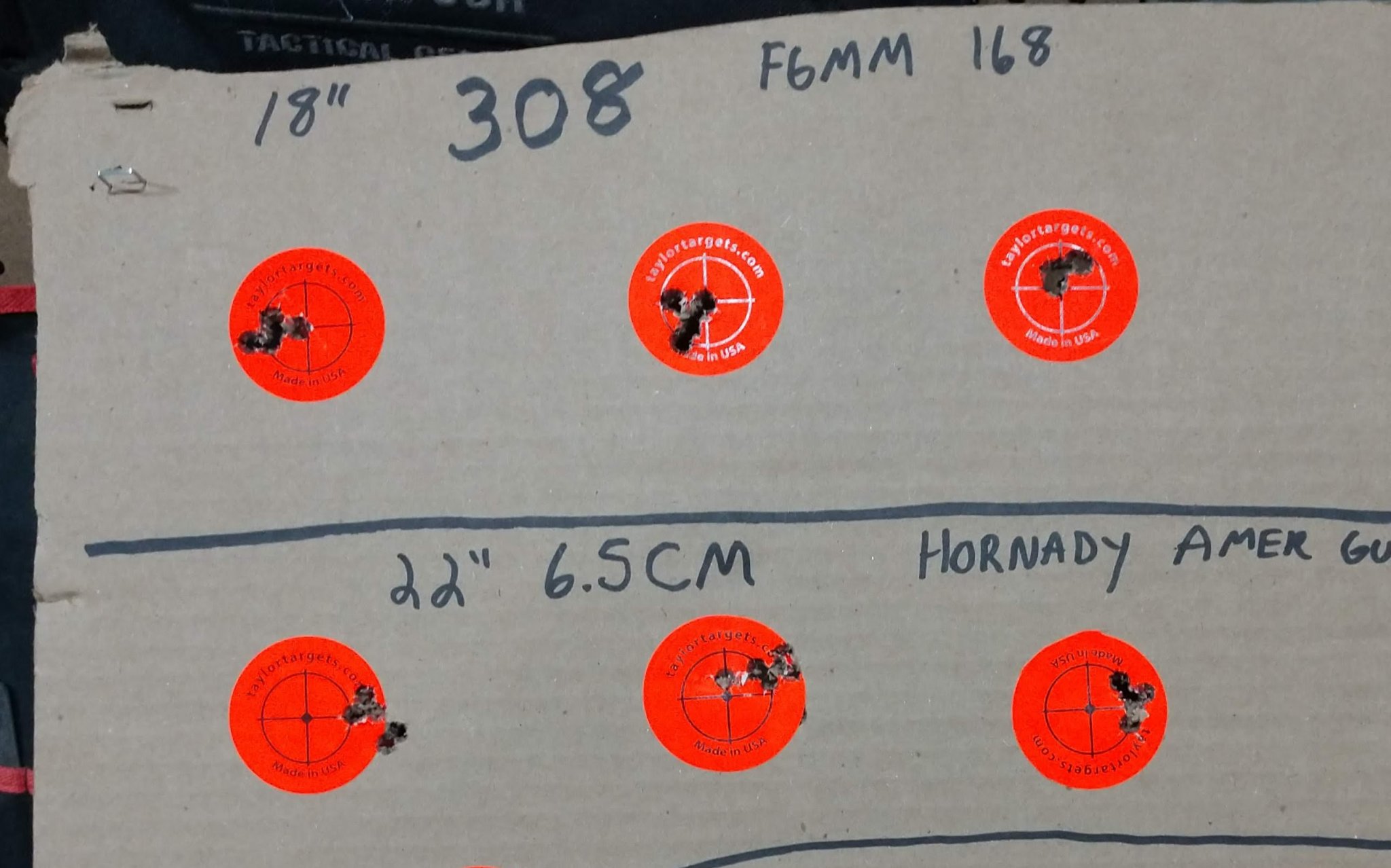

Currently the FDE PredatAR is running another Paul Ross Barrel in 6.5 Creedmoor.

20" 6.5CM Bartlein / 1-8 Twist / 4 Groove/ Medium Weight Modified M110 Contour / Rifle Length +1 gas system/ .800 Gas Block Journal that steps down to .790 to the Muzzle / 5/8x24 Threads / Oversized Barrel extension.

Area 419 Hellffire Muzzle Break.

.800 special order Rainer Arms AGB, made my Superlative Arms.

JP H2 SCS

Raidian Raptor Ambi Charging Handle

JP Ambi Mag release

Triggertech AR10 Diamond 2 Stage.

Luth MBA3 Adjustable Carbine Stock.

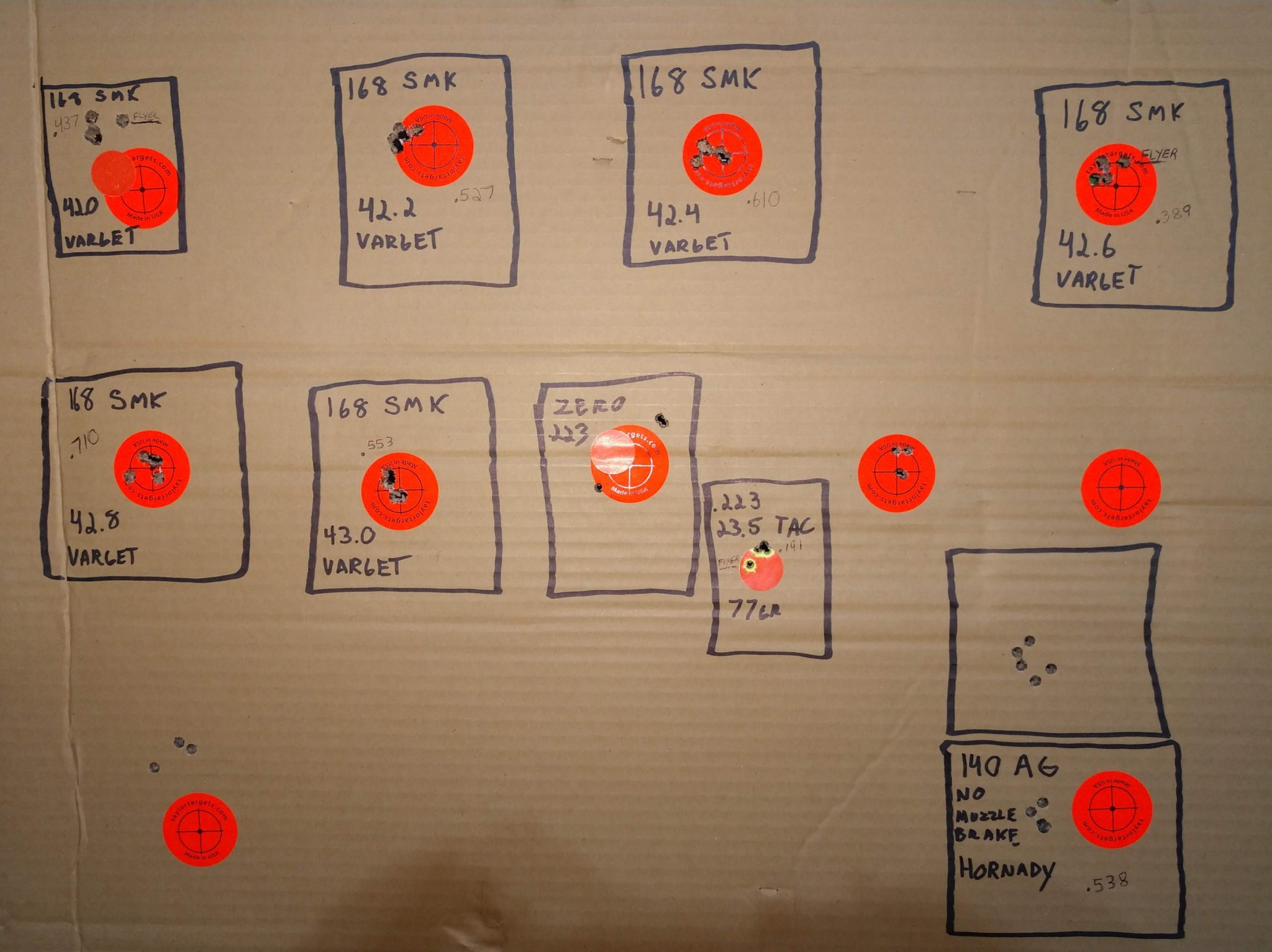

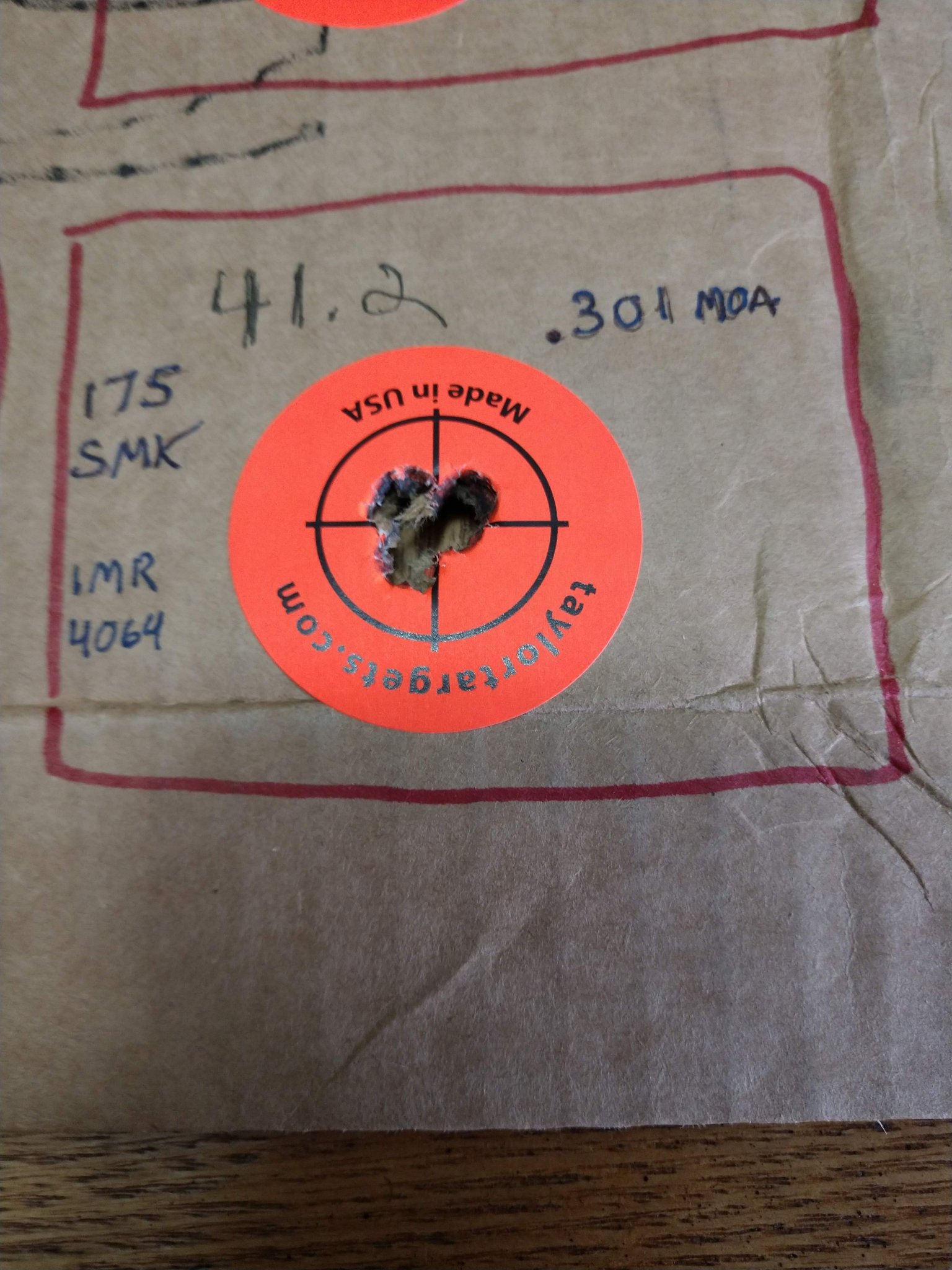

After rifle set-up and barrel Break-in I tried out the same OBR pet load of 140ELD /40.4grs H4350/ Lapua SRP Brass/ CCI BR4 Primers.

I shot one round to zero the Scope for the above Handload then shot a 5rd Group, I then passed the rifle over to my 70 year old Father-in-law who has only shot Large frame gasser a handful of times. As you can see the results speak for themselves.

In case any of you are wondering why I always use 4 Groove Bartlein's instead of 5R it's because it makes it easier to drill the Gas port directly in the center of a Groove, making Barrel/Gas Port Break-in go a lot smoother.

Thanks for reading.

Part 3 PredatOBR coming tomorrow.

Jake.

I've already done a review on my FDE PredatAR in the past so this review will be relatively short.

A lot of the same modifications that have been done on the (OBR Part 1) are the same as the PredatAR so no need to reiterate.

The FDE PredatAR has had multiple barrels and different calibers all very successful.

The original 16" .308 Larue barrel that came with the FDE Ptar was one of the worst I have ever owned, the XTRAXN chamber had extremely aggressive fluting and a oversized chamber that resulted in several issues that ranged from cracked cases just above the case heads, deformed extractor grooves due to case extraction during high chamber pressure, blown/ pierced primers and because of the oversized chamber the brass was rendered absolutely unusable.

I've seen these issues on several .308 Larue barrels but definitely not always consistent from gun to gun some have zero issues with function or resizing brass with 100% reliability.

There are multiple variations of the Larue .308 chambering jobs floating around, I've got several Larue barrels in my spare parts/junk bin that I'll post pics of to show the various inconsistent chamber work.

The original .308 Larue 16" Barrel, you could take a metal punch and run it over the chamber flutes and it would sounded like running you finger down a washboard.

The below images is a excellent illustration of what the brass looked like in the original 16" Larue Ptar barrel posted by another Larue owner who suffered from the same issues. (Not my Image)

I exhausted all options trying to make the original Larue Barrel work. I tried multiple brands of Sizing Dies, had Forster make a custom Sizing Die..Annealing the brass after every firing..Imperial Sizing Die Wax, but nothing worked.

The standard .308 Bolt that came with FDE Ptar had a chamferred firing pin hole that produced severe primer flow and pierced primers.

The pictures below shows the difference between the standard Larue .308 Bolt Vs the new HP Bolt and what a difference the new HP bolt makes.

(3 ) .308 Fired FGMM and (3) .308 Hot/High pressure Handloads.

The Small Rifle Primer 6.5CM Lapua Brass shot out of my custom Bartlein barrels come out even cleaner, majority of them are still going strong with 10+ firings

The first barrel I installed was a 18" .308 Bartlein from Paul Ross. 1-10 Twist/ 4 Groove / M110 Contour / RLG/ 5/8x24 Threads/ Oversized Barrel Extension.

The barrel design made the FDE Ptar perfectly balanced and a absolute pleasure to shoot.

To no surprise the Custom .308 Bartlein that Paul Ross turned was easily a Sub 1/2" MOA barrel with a variety of Handloads and factory ammo.

Currently the FDE PredatAR is running another Paul Ross Barrel in 6.5 Creedmoor.

20" 6.5CM Bartlein / 1-8 Twist / 4 Groove/ Medium Weight Modified M110 Contour / Rifle Length +1 gas system/ .800 Gas Block Journal that steps down to .790 to the Muzzle / 5/8x24 Threads / Oversized Barrel extension.

Area 419 Hellffire Muzzle Break.

.800 special order Rainer Arms AGB, made my Superlative Arms.

JP H2 SCS

Raidian Raptor Ambi Charging Handle

JP Ambi Mag release

Triggertech AR10 Diamond 2 Stage.

Luth MBA3 Adjustable Carbine Stock.

After rifle set-up and barrel Break-in I tried out the same OBR pet load of 140ELD /40.4grs H4350/ Lapua SRP Brass/ CCI BR4 Primers.

I shot one round to zero the Scope for the above Handload then shot a 5rd Group, I then passed the rifle over to my 70 year old Father-in-law who has only shot Large frame gasser a handful of times. As you can see the results speak for themselves.

In case any of you are wondering why I always use 4 Groove Bartlein's instead of 5R it's because it makes it easier to drill the Gas port directly in the center of a Groove, making Barrel/Gas Port Break-in go a lot smoother.

Thanks for reading.

Part 3 PredatOBR coming tomorrow.

Jake.

Last edited: