Here is the final product of my AR-10 and AR-15 projects, if you’d like to know more about how I got here, read on below the pictures and ensuing posts.

A few years ago, I created a thread called “Journey to my lightweight AR-10 build” or something to that effect; unfortunately, this post was on the old Scout site and all the threads have been lost to the internet ether forever. In that thread I walked the reader through the decision-making process and why I chose certain parts over others in my pursuit to build the lightest possible, but highly accurate, long range AR-10. The journey began with 308 Win in mind, because of my love for that cartridge (ever since I pummeled bunkers with the M60 some 30 years ago), but as luck would have it, the rifle transformed into a 6.5 Creedmoor almost overnight and that has been one of my favorite cartridges since. For this build I decided immediately on another 6.5 Creedmoor, besides, I had some parts sitting around for a new large frame AR build and decided to capitalize on some of those, but instead of pursuing the lightest rig this time around I instead focused on a more traditional (heavier) build. At the same time I was getting everything together for the large frame build I was tasked (for a friend) with building a precision AR-15 capable of 3 gun competitions but also for long range accuracy while keeping the weight down, so decided it would be fun to do a two part series about the nuances of building both rifles. Even though both rifles will ultimately be sold, I thought it would be fun to walk you through the process of the builds for each one.

First, we’ll start with the AR-10 6.5 Creedmoor build, or as I like to call them AR-6.5’s. I am calling this one the Custom Aero-BA 18” 6.5 Creedmoor.

Lower and Parts

Every AR build begins with the lower, this is the serial numbered part that must be purchased through an FFL.

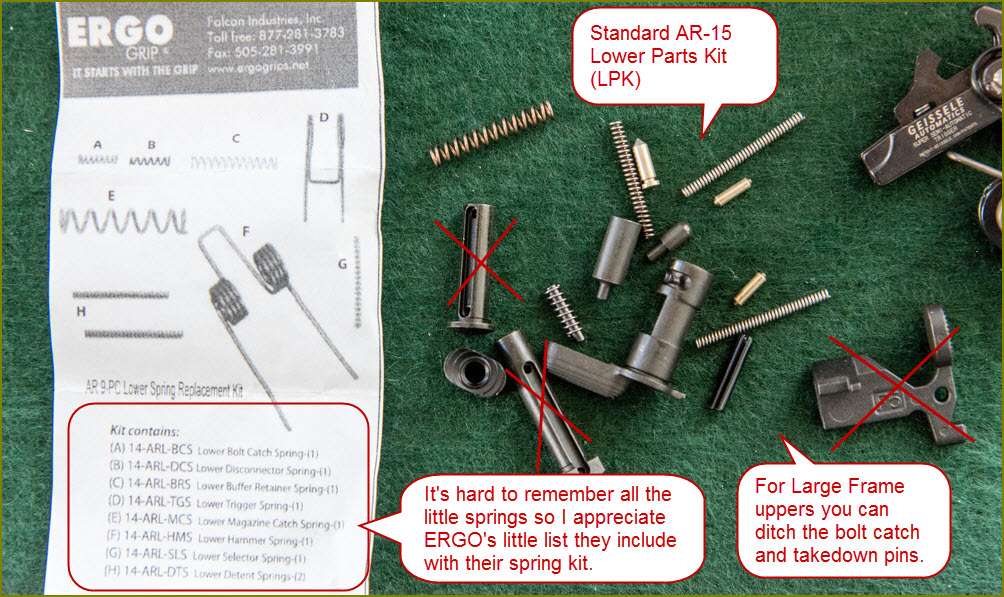

I chose to go with the Aero Precision M5 .308 forged lower in FDE due to its proven reliability over the years and the use of 7075-T6 aluminum helps this unit be more rigid, the FDE is personal preference but sometimes I get bored with all black rifles. The Aero uses a standard Lower Parts Kit, my preference is the JP LPK’s because they have always worked in multiple platforms for me. With large frame AR builds you will have to replace the takedown pins and bolt release catch, I opted to go with the Guntec USA AR-308 Extended Takedown Pin Set because I often find those pins hard to get out and the extended pins provide a lot more grip area to pull and for the bolt catch I chose the Phase 5 Tactical Extended Bolt Release V2 for two reasons, one, the Aero has had some issues with standard bolt releases not being able to catch the bolt sufficiently and two is I like ambidextrous releases so I can manipulate the magazine and bolt from my grip hand, the Phase 5 unit combines both features into one. I also have pretty big hands but often find the magazine release requires me to alter my grip in order to press that button, so I like the extended magazine releases, I chose the Odin Works XMR in FDE to match the FDE of the lower. One of the cool aspects of AR builds is there are so many little parts and pieces you have almost unlimited options to choose different colors, shapes and sizes to match a particular design you have in mind. Instead of using the rough triggers that come with most LPK’s I chose to use a 2-stage trigger and my favorite is made by Geiselle, for this build I chose the SSA trigger which has a 2.5 lb first stage and 2.0 lb second stage for a combined break of 4.5 lbs, these triggers are really smooth and consistent. Rounding out what’s needed with the lower is the stock, there are so many good options today it might be hard to choose from, but for precision long range I tend to prefer the full stocks vs. the collapsible stocks, for this build I chose the tried and true Magpul PRS Gen 3 Stock – FDE which requires a full A2 buffer tube, spring and full size buffer to handle the kick the 308 size cartridges give.

Upper and Parts

The upper provides the foundation for the bolt and barrel and needs to be built well initially to ensure precision later on, my advice is to not skimp with build technique with the upper because so much relies on everything being put together correctly, more so than small frame AR-15’s which are relatively “easy” to build and get to shoot with tight groups. For the upper I decided to match the Aero lower and purchased the Aero Precision M5 .308 7075-T6 Forged Assembled Upper Receiver, but unfortunately Aero did not have any FDE’s available at the time, so I went with the standard black knowing I would need to Cerakote the handguard anyway. The upper I purchased already came with the dust cover and forward assist installed but needed a charging handle and BCG (Bolt Carrier Group). I prefer to have a little larger latch on my charging handles so opted for the BCM Gunfighter with Mod 3 (Large) Latch made for large frame uppers, for the BCG there are many to choose from but since this build was for a 6.5 Creedmoor there are few who make BCG’s with the smaller diameter firing pin and I chose the Rubber City Armory (RCA) Standard Mass AR-10 HP with QPQ finish, HP stands for High Pressure as many 6.5mm calibers, and smaller, with 308 based cases deliver higher pressures than standard 308 and shooters have noticed they will sometimes get premature pressure signs like blown primers. The smaller diameter firing pin and bolt face firing pin hole help to alleviate these false pressure signs (if you are reloading keep your loads in close check with recommended loading techniques). The only manufacturer’s I know of who make this design for aftermarket builds is JP and RCA. Next up is the barrel and handguard. Since I don’t intend to shoot this rifle much beyond 1000 yards I decided to go with a shorter stiffer barrel and Ballistic Advantage has been getting a good reputation so went with the Premium Series 18" 1:8 6.5 Creedmoor 416R SS Barrel from Ballistic Advantage, this is a thick (stiff) barrel and should provide the foundation for some nice tight groups. Next up was the gas block and tube, BA uses a medium length tube for this barrel and I had the option to go with a regular low profile .875 dia. gas block or an adjustable gas block (AGB), if this were intended to be shot suppressed I would go with an AGB but for this build chose a standard Cross Machine J.A.G. gas block. To finish off the upper I needed to find the right handguard and accessories. I chose the Fortis (Rainier Style) 14" 308 SWITCH Keymod Rail due to its unique design with the angled front end that allows for a bipod rail to be edged out just a bit forward and I like the quick release design and solid lock up of the SWITCH. For a while I thought I might go with a 2-tone design with a black upper and FDE lower, but decided in the end to send the upper and handguard off to my gunsmith to get Cerakoted in the same FDE as the lower. For accessories I put on a Naroh Arms Keymod Barrier Stop and a Seekins Precision KM 5-slot Rail Section for bipods.

Edit: You might be wondering why I went with the basic A2 flash hider, because I did not build these rifles for my personal use and because muzzle devices are one of the easiest to replace I decided not to invest in an expensive one but allow the buyer to choose.

As one of my favorite movie characters once chided "Let's get down to the nitty gritty..." (quote from Nacho Libre)

I’m a camera guy but not much of a video guy, so this thread is going to be picture heavy. They say a picture is worth a thousand words so this is my way of writing 50,000 words without having to write “fifty thousand words” ?

The build pictures are pretty self explanatory especially with the callout notes but please let me know if I did anything out of order and inquire if your curious as to why I did something a particular way.

A few years ago, I created a thread called “Journey to my lightweight AR-10 build” or something to that effect; unfortunately, this post was on the old Scout site and all the threads have been lost to the internet ether forever. In that thread I walked the reader through the decision-making process and why I chose certain parts over others in my pursuit to build the lightest possible, but highly accurate, long range AR-10. The journey began with 308 Win in mind, because of my love for that cartridge (ever since I pummeled bunkers with the M60 some 30 years ago), but as luck would have it, the rifle transformed into a 6.5 Creedmoor almost overnight and that has been one of my favorite cartridges since. For this build I decided immediately on another 6.5 Creedmoor, besides, I had some parts sitting around for a new large frame AR build and decided to capitalize on some of those, but instead of pursuing the lightest rig this time around I instead focused on a more traditional (heavier) build. At the same time I was getting everything together for the large frame build I was tasked (for a friend) with building a precision AR-15 capable of 3 gun competitions but also for long range accuracy while keeping the weight down, so decided it would be fun to do a two part series about the nuances of building both rifles. Even though both rifles will ultimately be sold, I thought it would be fun to walk you through the process of the builds for each one.

First, we’ll start with the AR-10 6.5 Creedmoor build, or as I like to call them AR-6.5’s. I am calling this one the Custom Aero-BA 18” 6.5 Creedmoor.

Lower and Parts

Every AR build begins with the lower, this is the serial numbered part that must be purchased through an FFL.

I chose to go with the Aero Precision M5 .308 forged lower in FDE due to its proven reliability over the years and the use of 7075-T6 aluminum helps this unit be more rigid, the FDE is personal preference but sometimes I get bored with all black rifles. The Aero uses a standard Lower Parts Kit, my preference is the JP LPK’s because they have always worked in multiple platforms for me. With large frame AR builds you will have to replace the takedown pins and bolt release catch, I opted to go with the Guntec USA AR-308 Extended Takedown Pin Set because I often find those pins hard to get out and the extended pins provide a lot more grip area to pull and for the bolt catch I chose the Phase 5 Tactical Extended Bolt Release V2 for two reasons, one, the Aero has had some issues with standard bolt releases not being able to catch the bolt sufficiently and two is I like ambidextrous releases so I can manipulate the magazine and bolt from my grip hand, the Phase 5 unit combines both features into one. I also have pretty big hands but often find the magazine release requires me to alter my grip in order to press that button, so I like the extended magazine releases, I chose the Odin Works XMR in FDE to match the FDE of the lower. One of the cool aspects of AR builds is there are so many little parts and pieces you have almost unlimited options to choose different colors, shapes and sizes to match a particular design you have in mind. Instead of using the rough triggers that come with most LPK’s I chose to use a 2-stage trigger and my favorite is made by Geiselle, for this build I chose the SSA trigger which has a 2.5 lb first stage and 2.0 lb second stage for a combined break of 4.5 lbs, these triggers are really smooth and consistent. Rounding out what’s needed with the lower is the stock, there are so many good options today it might be hard to choose from, but for precision long range I tend to prefer the full stocks vs. the collapsible stocks, for this build I chose the tried and true Magpul PRS Gen 3 Stock – FDE which requires a full A2 buffer tube, spring and full size buffer to handle the kick the 308 size cartridges give.

Upper and Parts

The upper provides the foundation for the bolt and barrel and needs to be built well initially to ensure precision later on, my advice is to not skimp with build technique with the upper because so much relies on everything being put together correctly, more so than small frame AR-15’s which are relatively “easy” to build and get to shoot with tight groups. For the upper I decided to match the Aero lower and purchased the Aero Precision M5 .308 7075-T6 Forged Assembled Upper Receiver, but unfortunately Aero did not have any FDE’s available at the time, so I went with the standard black knowing I would need to Cerakote the handguard anyway. The upper I purchased already came with the dust cover and forward assist installed but needed a charging handle and BCG (Bolt Carrier Group). I prefer to have a little larger latch on my charging handles so opted for the BCM Gunfighter with Mod 3 (Large) Latch made for large frame uppers, for the BCG there are many to choose from but since this build was for a 6.5 Creedmoor there are few who make BCG’s with the smaller diameter firing pin and I chose the Rubber City Armory (RCA) Standard Mass AR-10 HP with QPQ finish, HP stands for High Pressure as many 6.5mm calibers, and smaller, with 308 based cases deliver higher pressures than standard 308 and shooters have noticed they will sometimes get premature pressure signs like blown primers. The smaller diameter firing pin and bolt face firing pin hole help to alleviate these false pressure signs (if you are reloading keep your loads in close check with recommended loading techniques). The only manufacturer’s I know of who make this design for aftermarket builds is JP and RCA. Next up is the barrel and handguard. Since I don’t intend to shoot this rifle much beyond 1000 yards I decided to go with a shorter stiffer barrel and Ballistic Advantage has been getting a good reputation so went with the Premium Series 18" 1:8 6.5 Creedmoor 416R SS Barrel from Ballistic Advantage, this is a thick (stiff) barrel and should provide the foundation for some nice tight groups. Next up was the gas block and tube, BA uses a medium length tube for this barrel and I had the option to go with a regular low profile .875 dia. gas block or an adjustable gas block (AGB), if this were intended to be shot suppressed I would go with an AGB but for this build chose a standard Cross Machine J.A.G. gas block. To finish off the upper I needed to find the right handguard and accessories. I chose the Fortis (Rainier Style) 14" 308 SWITCH Keymod Rail due to its unique design with the angled front end that allows for a bipod rail to be edged out just a bit forward and I like the quick release design and solid lock up of the SWITCH. For a while I thought I might go with a 2-tone design with a black upper and FDE lower, but decided in the end to send the upper and handguard off to my gunsmith to get Cerakoted in the same FDE as the lower. For accessories I put on a Naroh Arms Keymod Barrier Stop and a Seekins Precision KM 5-slot Rail Section for bipods.

Edit: You might be wondering why I went with the basic A2 flash hider, because I did not build these rifles for my personal use and because muzzle devices are one of the easiest to replace I decided not to invest in an expensive one but allow the buyer to choose.

As one of my favorite movie characters once chided "Let's get down to the nitty gritty..." (quote from Nacho Libre)

I’m a camera guy but not much of a video guy, so this thread is going to be picture heavy. They say a picture is worth a thousand words so this is my way of writing 50,000 words without having to write “fifty thousand words” ?

The build pictures are pretty self explanatory especially with the callout notes but please let me know if I did anything out of order and inquire if your curious as to why I did something a particular way.

Last edited: