I'm not a gunsmith or an expert, so I will say that upfront, but I have done a ton of R&D with my JP LRI-20. Repeatable precision accuracy in an AR platform is challenging; the operating system movement and how you manage it are factors. I have been working on R&D for about a year now and have gotten my rifle close to my goals on most days. The original goal was to build an AR platform that consistently shoots as well as my bolt rifles out to semi-ELR (1000 yards).

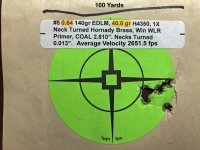

In a short summary, I have refined the combination with my rig and my load, but still find that unless I manage the movement, I end up with a "flyer" per se. Below are two examples: one where I properly managed the rifle and one where I made an error on one of the shots. It's still a tight group, but something I wanted to figure out how to eliminate.

What I have found is that the load makes a difference for both accuracy and brass life, but the operating system is equally important with 6.5.

From a load standpoint, second-fired brass that has been form-fitted and then FL resized with a bump works better in my rifle. It seems my AR barrels are chambered with more tolerance and expand a lot during fire, regardless of the load. I also had much better results when I switched to small primers. However, I am not shooting in any type of extreme cold environment.

Small primer Lapua Brass (2nd fired with the shoulder bumped 0.002)

2.815" COL

42.2 g RL16

Hornady 143 ELDX

22" Bartlein barrel suppressed

2754 FPS

4.1 SD