If it really is a curvature issue or a corner radius/defect issue with the brass, then the narrow end of the caliper tailstock can be used to check the difference near the outer diameter of the pocket versus the center.

If the OP has a pocket uniforming cutter, then a light touch without intentional cutting can show those issues.

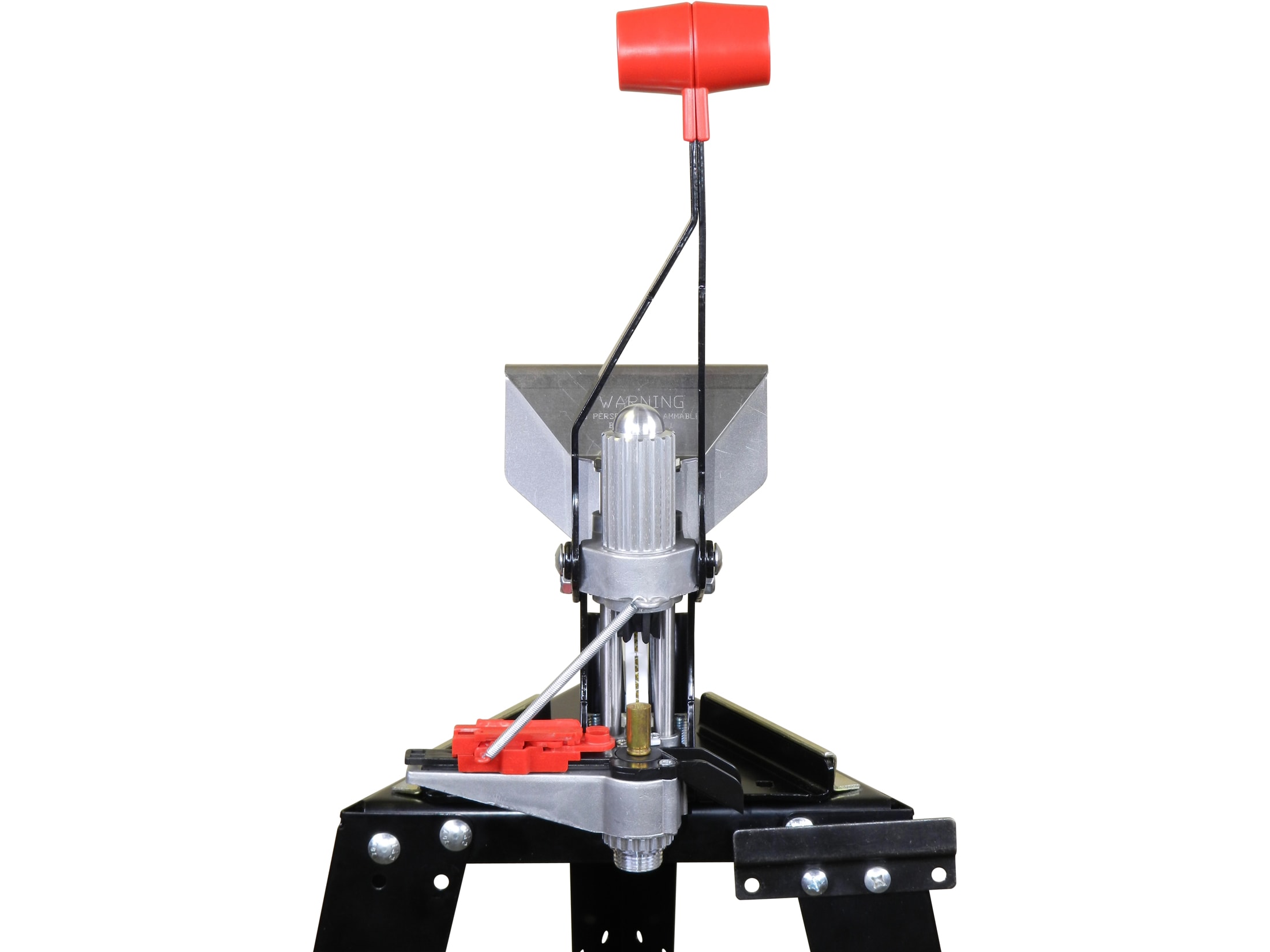

The Accuracy One probe anvil is contacting near the outer diameter and the whole point of the concave end versus the flat end is to give the user their preference for the potential differences in resting on those places.

Lets say there might be a defect in the tooling for talking purposes.

If we were in the labs, to debug this I would first take a good stereo microscope and examine several pieces of the brass pockets to look for anything that might explain this quickly. Failing that, I would proceed to test the instrument.

A 1-2-3 block and a set of gage blocks can be set up to create a height difference to very fine accuracy and the instrument should read those steps to within less than the 0.005" the OP is reporting.

Hard to say if the OP would have access to a very flat reference and some gage blocks, but you can fake this with anything that is ground parallel and roughly the correct height difference and a hole or step that will support the instrument base. A micrometer caliper can be used to measure anything close enough to substitute for gage blocks and answer the fundamental questions.

Like we see in those linked videos, there can be errors due to the null and resolution of the gage combined with the play of the anvil probe. Add in the less than perfect surfaces of brass cartridge bases and primer pockets, and my guess is you would only expect to be within +/- 0.001" if the brass is in good shape. I agree that there shouldn't be an unexplained 0.005" bias between the two methods, so something sounds wrong.

When I am running large batches of brass, I sometimes get an unexpected reading. I stop and double check if it is me, the tool, or the brass is really to blame. If you spin brass or recheck, you will usually get to the bottom of a bad reading without a research project. However, getting a 0.005" bias across the board is not normal. Something will jump out if the OP takes a closer look.