...are all moving towards one thing. Setting aside all terminal ballistics, and only focusing on flight:

Bullet designs have gotten incrementally better since I started shooting in the 1970s. New bullets come out with a slightly higher BC. Yet...

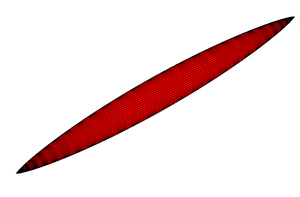

The physics is the physics. We have known, both theoretically/mathematically on paper and through testing, what shape has the lowest drag coefficient and therefore the highest BC since 1947. The Sears-Haack body is the shape of an object with the lowest possible fluid drag.

The more a bullet looks like that the higher BC it's going to have and the slower the delta of speed as drag acts on it as it moves through air. There simply AREN'T "advancements" in bullet design when the most efficient shape possible has been around for 75+ years. Yea, there are materials, bonding, etc., but none of that is going to make it fly any better. Why isn't there a VLD that is literally a Sears-Haack body? Why isn't every competition bullet a Sears-Haack body? Is the symmetrical ogive at the rear some manufacturing or reloading problem? Am I missing something obvious? Really, as I look at the progression of bullets I've used I can literally see them getting more and more like a Sears-Haack. Is there something stopping us from just going directly to it? Is it too costly, or is it not possible to point both ends? I mean, there must be some valid reason I'm missing, because it's not like the best possible shape is a secret. Hell, if it is some manufacturing process problem then why not just weld two flat back bullets together? There is always going to be a market for the best, and we have always known exactly what that is.

Is someone somewhere crafting these for their own use? People are turning monolithic bullets, but I haven't seen one that was literally a Sears-Haack. Why, or are they out there?

Maybe this whole line of thinking is dumb, I don't know, but I've seen a thousand posts about a new bullet design, when there's really only a single one, and every bullet that doesn't care about terminal ballistics wants to be that one design.

Bullet designs have gotten incrementally better since I started shooting in the 1970s. New bullets come out with a slightly higher BC. Yet...

The physics is the physics. We have known, both theoretically/mathematically on paper and through testing, what shape has the lowest drag coefficient and therefore the highest BC since 1947. The Sears-Haack body is the shape of an object with the lowest possible fluid drag.

The more a bullet looks like that the higher BC it's going to have and the slower the delta of speed as drag acts on it as it moves through air. There simply AREN'T "advancements" in bullet design when the most efficient shape possible has been around for 75+ years. Yea, there are materials, bonding, etc., but none of that is going to make it fly any better. Why isn't there a VLD that is literally a Sears-Haack body? Why isn't every competition bullet a Sears-Haack body? Is the symmetrical ogive at the rear some manufacturing or reloading problem? Am I missing something obvious? Really, as I look at the progression of bullets I've used I can literally see them getting more and more like a Sears-Haack. Is there something stopping us from just going directly to it? Is it too costly, or is it not possible to point both ends? I mean, there must be some valid reason I'm missing, because it's not like the best possible shape is a secret. Hell, if it is some manufacturing process problem then why not just weld two flat back bullets together? There is always going to be a market for the best, and we have always known exactly what that is.

Is someone somewhere crafting these for their own use? People are turning monolithic bullets, but I haven't seen one that was literally a Sears-Haack. Why, or are they out there?

Maybe this whole line of thinking is dumb, I don't know, but I've seen a thousand posts about a new bullet design, when there's really only a single one, and every bullet that doesn't care about terminal ballistics wants to be that one design.