Yep, I posted an inquiry about it years ago. Then there was the Gradous? AW in a Mcmillan thread that vanished. And all these gems too:

http://www.snipershide.com/shooting/threads/ai-in-a-mcmillan-or-manners-stock-questions.55358/

http://www.snipershide.com/shooting...uying-an-ai-ae-mki-as-a-doner-action.6313256/

https://www.snipershide.com/shooting/threads/ai-ae-mark-iii-in-a-fiberglass-stock.177711/

I want to hear some thoughts on this line of thinking:

So, traditionally, people thought you could remove the action and have a gunsmith work some voodoo on maybe some custom bottom metal and recoil lug and possibly drill the receiver behind the recoil lug. I set up an AE next to an Impact and you can note the spacing, of both sets of action screws. Could you get lucky an line it up with some bottom metal?...maybe. Would it feed?...I doubt I would be that lucky.

But what about this?

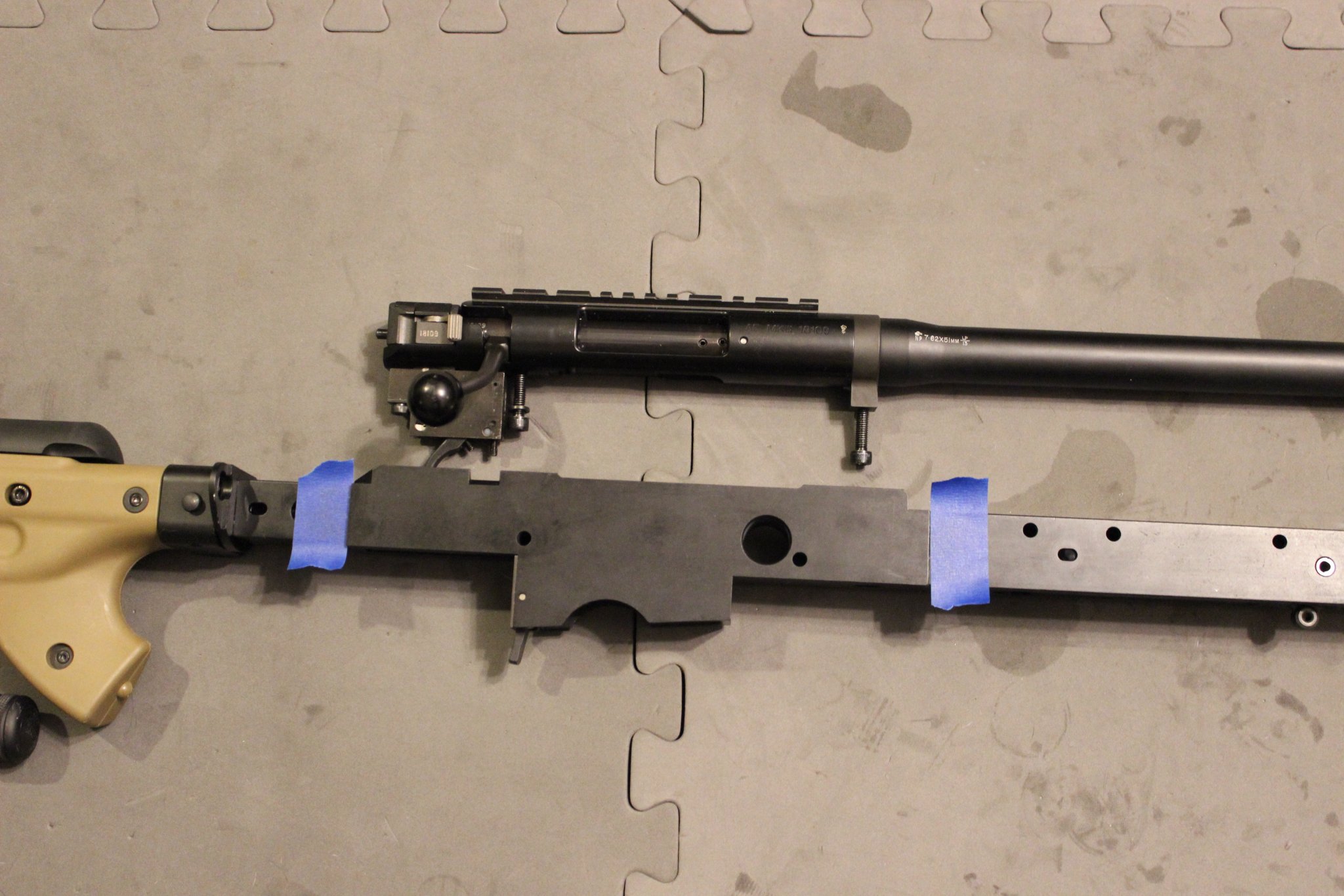

Lets just say you harvest part of the existing chassis as well. In a sense...make it its own "mini chassis". Could one not merely use the portion inside the blue tape (or more), inlet the stock for it and bed it in and bolt it from the left/right sides like a Manners mini chassis? Overall thickness (outside to outside) of the chassis is 1.25".

@RobertB, think there's enough meet in a Manners to do that?

Thoughts?

Sorry, but I just can't get this monkey off my back re: and AI/Manners hybrid

http://www.snipershide.com/shooting/threads/ai-in-a-mcmillan-or-manners-stock-questions.55358/

http://www.snipershide.com/shooting...uying-an-ai-ae-mki-as-a-doner-action.6313256/

https://www.snipershide.com/shooting/threads/ai-ae-mark-iii-in-a-fiberglass-stock.177711/

I want to hear some thoughts on this line of thinking:

So, traditionally, people thought you could remove the action and have a gunsmith work some voodoo on maybe some custom bottom metal and recoil lug and possibly drill the receiver behind the recoil lug. I set up an AE next to an Impact and you can note the spacing, of both sets of action screws. Could you get lucky an line it up with some bottom metal?...maybe. Would it feed?...I doubt I would be that lucky.

But what about this?

Lets just say you harvest part of the existing chassis as well. In a sense...make it its own "mini chassis". Could one not merely use the portion inside the blue tape (or more), inlet the stock for it and bed it in and bolt it from the left/right sides like a Manners mini chassis? Overall thickness (outside to outside) of the chassis is 1.25".

@RobertB, think there's enough meet in a Manners to do that?

Thoughts?

Sorry, but I just can't get this monkey off my back re: and AI/Manners hybrid