I've come across a frustratingly large number of fired Alpha Dasher cases that will no longer chamber (easily) in the rifle from which they were fired.

For the cases that dont chamber (easily), I've found that the lip of the case neck will measure 0.273-0.2735 with a seated round...and my chamber is 0.274. As a result, chambering and extracting is not possible without a rubber mallet.

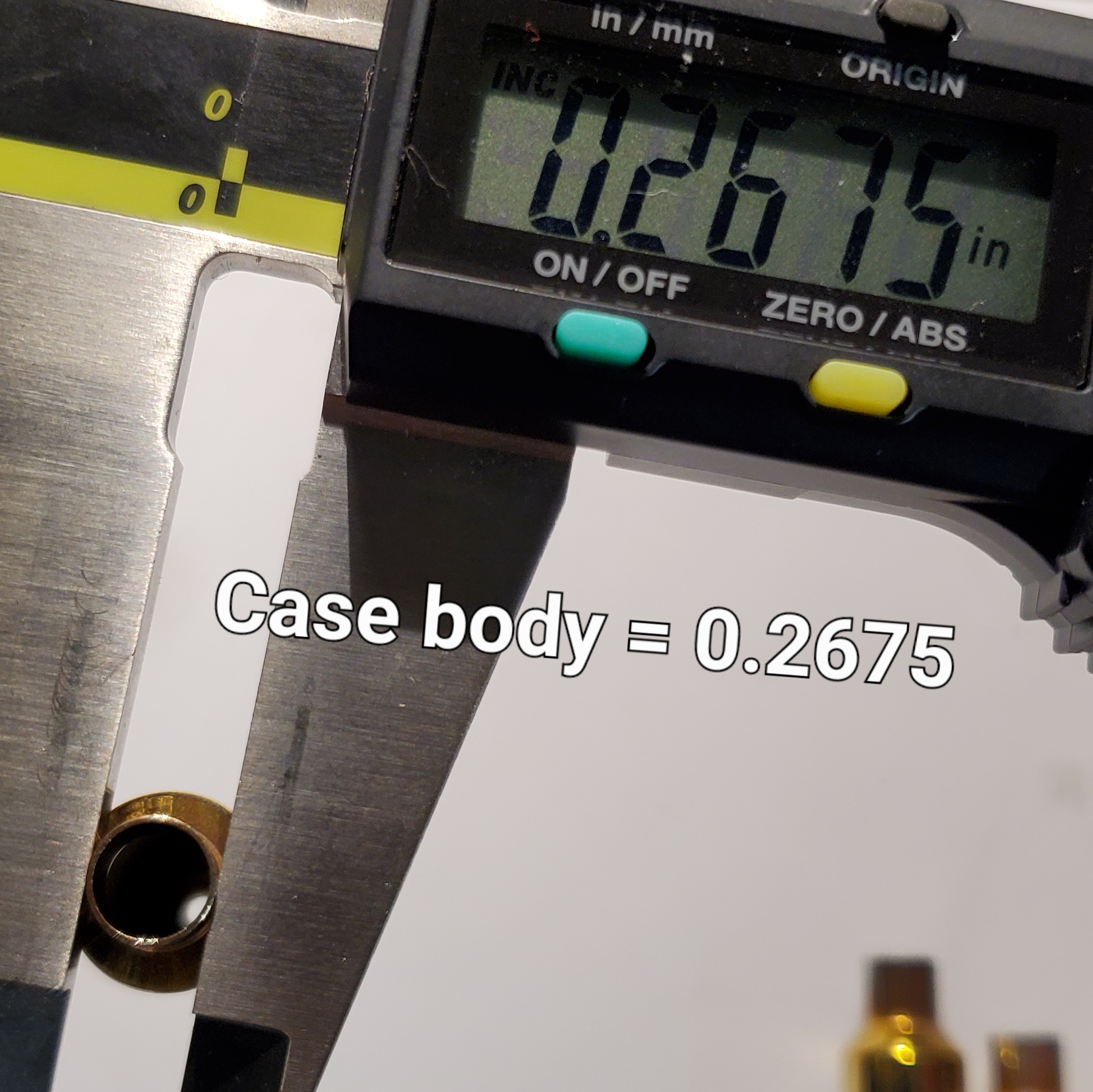

I've also found that when I neck size down in my 0.267 bushing, the lips and the body of the case neck (for the most part) measure out to ~0.267 +/- 0.0005. But, it's only when I go to the expander mandrel from PMA Tool that the lips get way over sized to 0.270 while the body remains 0.267

Reloading process:

- Wet tumble w/SS pins

- Anneal with AMP induction

- Bump/Neck size w/ 0.267 bushing

- Mandrel with PMA Tool 6mm expander mandrel (which im told is 0.242 for a final inside diameter of 0.241 after spring back)

- Wet tumble again to wash off lube

* note, this is 1-2x fired and dont require trim based on my measurments

So...my questions are as follows:

1) How to I remove the material from the lips of the case neck so that the entire neck is 0.267? Ive tried using the Lyment case prep express to chamfer the outsides...but it won't remove enough.

2) Is there a step in my process where I was supposed to address this?

3) Has anyone else encountered this with Alpha or other brass? I've also seen this relationship exists with virgin Alpha Dasher brass whereby there will be a ring around the lips that can measure 2-2.5 thou wider than the case neck body. See pics below.

4) What could cause the mandrel to create this fishmouthing of the case lips?

For the cases that dont chamber (easily), I've found that the lip of the case neck will measure 0.273-0.2735 with a seated round...and my chamber is 0.274. As a result, chambering and extracting is not possible without a rubber mallet.

I've also found that when I neck size down in my 0.267 bushing, the lips and the body of the case neck (for the most part) measure out to ~0.267 +/- 0.0005. But, it's only when I go to the expander mandrel from PMA Tool that the lips get way over sized to 0.270 while the body remains 0.267

Reloading process:

- Wet tumble w/SS pins

- Anneal with AMP induction

- Bump/Neck size w/ 0.267 bushing

- Mandrel with PMA Tool 6mm expander mandrel (which im told is 0.242 for a final inside diameter of 0.241 after spring back)

- Wet tumble again to wash off lube

* note, this is 1-2x fired and dont require trim based on my measurments

So...my questions are as follows:

1) How to I remove the material from the lips of the case neck so that the entire neck is 0.267? Ive tried using the Lyment case prep express to chamfer the outsides...but it won't remove enough.

2) Is there a step in my process where I was supposed to address this?

3) Has anyone else encountered this with Alpha or other brass? I've also seen this relationship exists with virgin Alpha Dasher brass whereby there will be a ring around the lips that can measure 2-2.5 thou wider than the case neck body. See pics below.

4) What could cause the mandrel to create this fishmouthing of the case lips?

Last edited: