American Rifle Company, M5 Bolt Action, The Mausingfield - YouTube

Hi all,

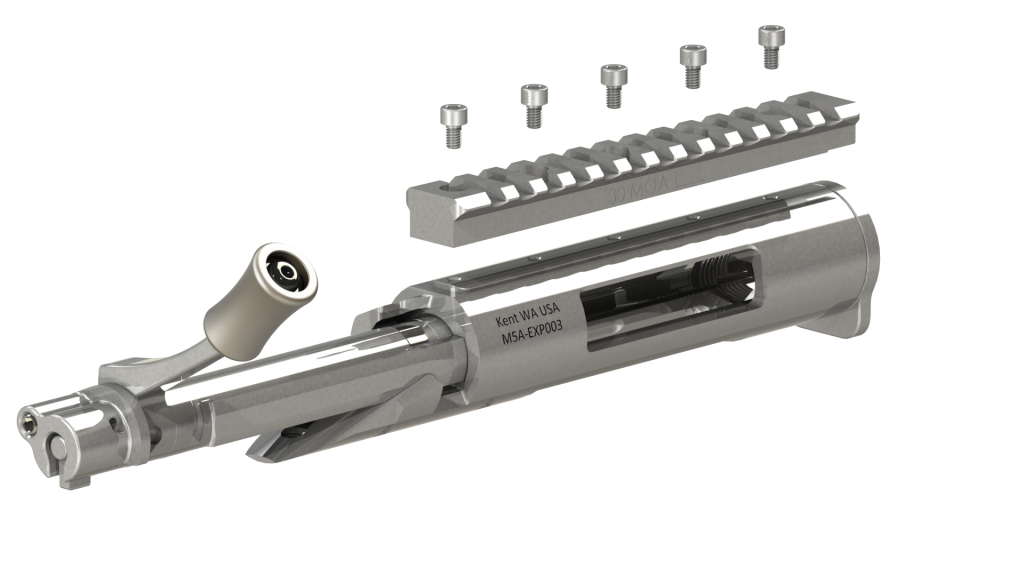

I’d like to introduce the American Rifle’s M5 Bolt Action, dubbed the Mausingfield. I designed this for custom builders who desired an action with a Rem 700 footprint. If you are at the Shot Show, swing buy booth 2701 to have a look at it. I’d also like to thank Mark Gordon of Short Actions customs for building the rifle on display at our booth and for his collaboration during design.

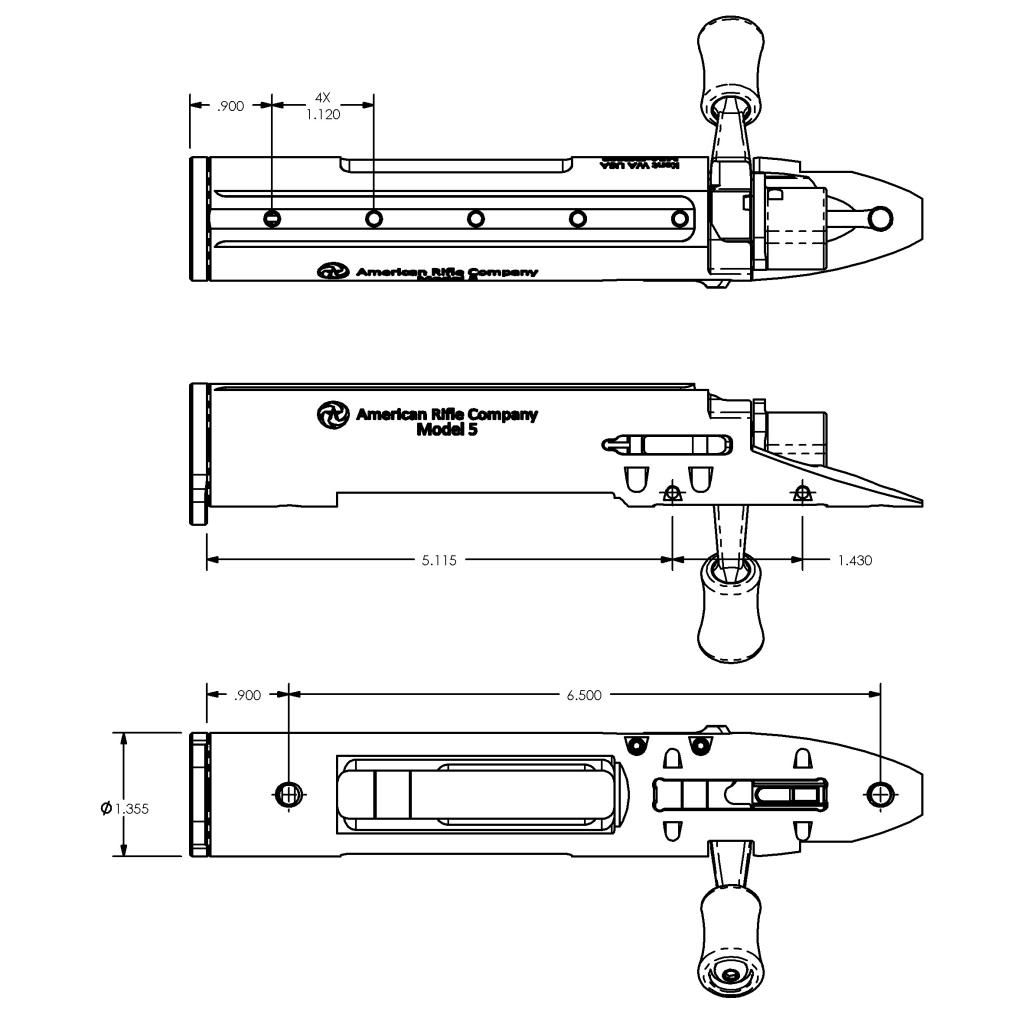

Externally the action is the same size as the 700 SA. Long actions and left hand versions will also be available. The action is compatible with triggers, bottom metal, and chassis systems that work with the M700. In is designed for use with AICS mags and not the AW mags. I don’t recommend fitting an AW mag to the M5 Mausingfield or a Remington 700 clone because doing so butchers the bottom of the action. At some point, I plan on making double-stack center-feed mags that will be more compact that the AICS mags but for now, AICS mags will have to do.

The rail is not M700 compatible nor is it an integral part of the receiver. It can be swapped out in order to change the inclination. The rail is secured to the receiver by way of five 8-36 x ¼” long standard socket head cap screws and a tapered key that eliminates the possibility of slippage.

The recoil lug is an integral part of the receiver.

A Mauser style bolt and extractor is used because Mauser system offers the best chance of extracting a case stubbornly stuck in the chamber. A toroidal bolt lug bearing surface engages a corresponding spherical bearing surface within the receiver so that the bolt lugs can only properly contact the receiver. Lapping is unnecessary as is a floating bolt head or any other scheme for establishing proper contact between the lugs and the receiver. As always, the best solution to a problem is the elimination of the cause of the problem. With this lug design, I could predictably control contact and therefore stress which allowed me to reduce the size of the lugs making room for a Mauser style extractor that can snap over the rim of a case already in the chamber. Most of what has been published on the internet and in many books about bolt lugs shearing off is incorrect. This is not the failure mode that one should be concerned with when designing bolt action. I’m not going to get into the details of this but modern FEA techniques offer us the ability to really understand the interaction between bolt and receiver.

I incorporated a 1903 Springfield style ejector because it is an extremely smart, robust, and reliable design. It is completely passive, forcefully driven into engagement with the case by the reward moving bolt without pins or springs to get stuck, corrode, or otherwise fail.

I don’t like to discuss metallurgy and heat treatment but rest assured that I am only using well controlled steels commonly used in aerospace. I don’t like the aerospace buzz word because it is over used but these material really do offer significant piece of mind and advantages especially in regards to manufacturing.

The barrel thread is 1.090” – 16.

I like the action more than I thought I would while I was designing it. Its development consumed valuable bandwidth I would have otherwise used for the development of the M2 but some of the M5’s attributes were incorporated in the M2. In the end, I think this is now the best M700 clone available because it is not really a clone while most others are. I cherry picked the best designs and solved the lug contact problem using modern engineering techniques. I regard lug lapping and floating bolt head as Band-Aids on wounds that shouldn’t exist. So, for your next build, please seriously consider using the American Rifle’s M5 Mausingfield.

Enjoy…

Hi all,

I’d like to introduce the American Rifle’s M5 Bolt Action, dubbed the Mausingfield. I designed this for custom builders who desired an action with a Rem 700 footprint. If you are at the Shot Show, swing buy booth 2701 to have a look at it. I’d also like to thank Mark Gordon of Short Actions customs for building the rifle on display at our booth and for his collaboration during design.

Externally the action is the same size as the 700 SA. Long actions and left hand versions will also be available. The action is compatible with triggers, bottom metal, and chassis systems that work with the M700. In is designed for use with AICS mags and not the AW mags. I don’t recommend fitting an AW mag to the M5 Mausingfield or a Remington 700 clone because doing so butchers the bottom of the action. At some point, I plan on making double-stack center-feed mags that will be more compact that the AICS mags but for now, AICS mags will have to do.

The rail is not M700 compatible nor is it an integral part of the receiver. It can be swapped out in order to change the inclination. The rail is secured to the receiver by way of five 8-36 x ¼” long standard socket head cap screws and a tapered key that eliminates the possibility of slippage.

The recoil lug is an integral part of the receiver.

A Mauser style bolt and extractor is used because Mauser system offers the best chance of extracting a case stubbornly stuck in the chamber. A toroidal bolt lug bearing surface engages a corresponding spherical bearing surface within the receiver so that the bolt lugs can only properly contact the receiver. Lapping is unnecessary as is a floating bolt head or any other scheme for establishing proper contact between the lugs and the receiver. As always, the best solution to a problem is the elimination of the cause of the problem. With this lug design, I could predictably control contact and therefore stress which allowed me to reduce the size of the lugs making room for a Mauser style extractor that can snap over the rim of a case already in the chamber. Most of what has been published on the internet and in many books about bolt lugs shearing off is incorrect. This is not the failure mode that one should be concerned with when designing bolt action. I’m not going to get into the details of this but modern FEA techniques offer us the ability to really understand the interaction between bolt and receiver.

I incorporated a 1903 Springfield style ejector because it is an extremely smart, robust, and reliable design. It is completely passive, forcefully driven into engagement with the case by the reward moving bolt without pins or springs to get stuck, corrode, or otherwise fail.

I don’t like to discuss metallurgy and heat treatment but rest assured that I am only using well controlled steels commonly used in aerospace. I don’t like the aerospace buzz word because it is over used but these material really do offer significant piece of mind and advantages especially in regards to manufacturing.

The barrel thread is 1.090” – 16.

I like the action more than I thought I would while I was designing it. Its development consumed valuable bandwidth I would have otherwise used for the development of the M2 but some of the M5’s attributes were incorporated in the M2. In the end, I think this is now the best M700 clone available because it is not really a clone while most others are. I cherry picked the best designs and solved the lug contact problem using modern engineering techniques. I regard lug lapping and floating bolt head as Band-Aids on wounds that shouldn’t exist. So, for your next build, please seriously consider using the American Rifle’s M5 Mausingfield.

Enjoy…