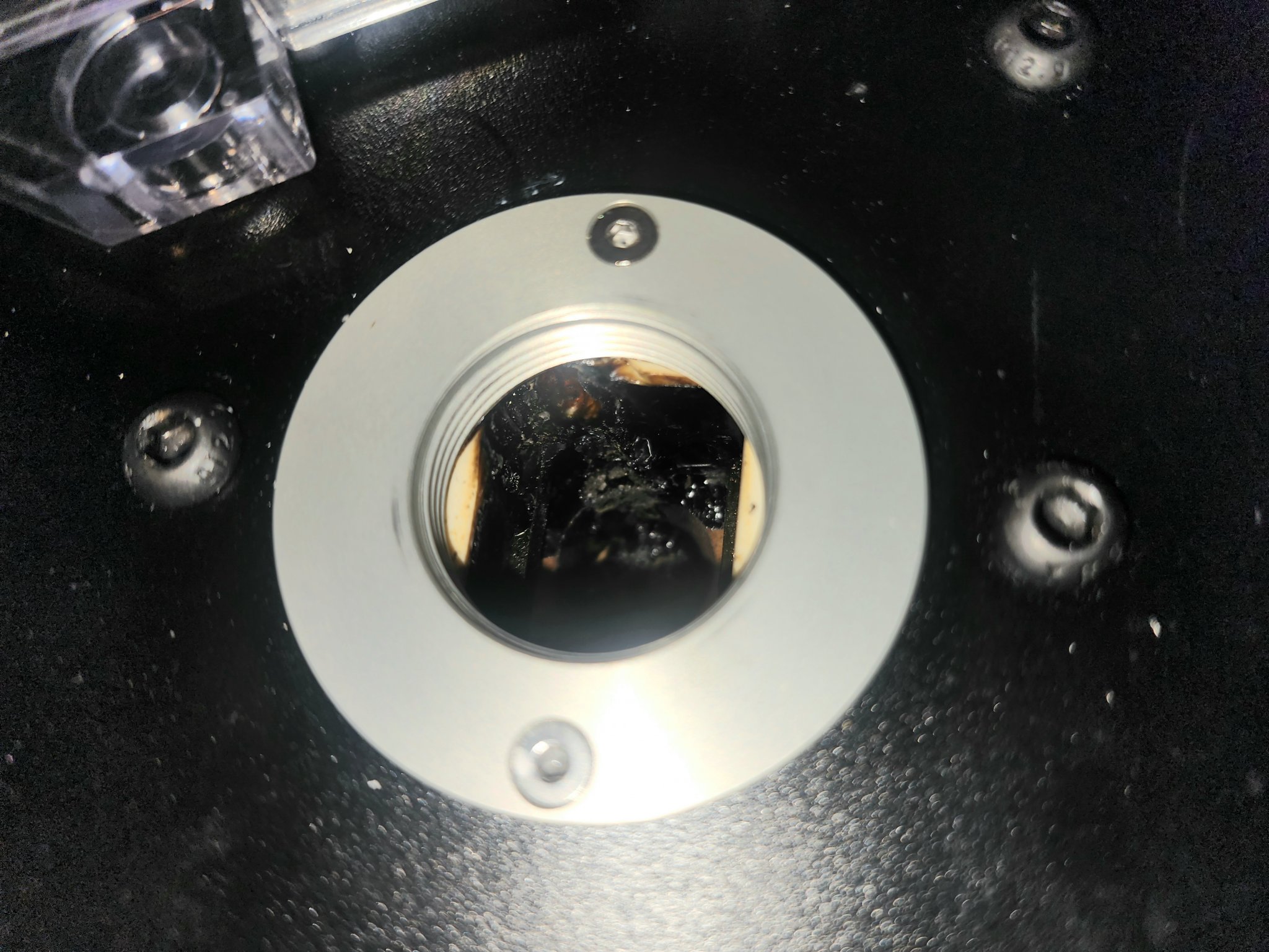

I bought this amp and amp mate. It was working great. Had it running over in the corner and this happened. Case some how came loose from shell holder. Burnt the case up worse then aztec analysis mode and basically destroyed the inner protective plastic.

This really sucks! Plastic melted down into the ceramic bowl.

Now that I think of it, I don't really know why plastic is anywhere near the heating source. I am hoping they take care of it. Preferably send replacement parts and ill do it myself. I just sent him an email tonight. What do you think?

This really sucks! Plastic melted down into the ceramic bowl.

Now that I think of it, I don't really know why plastic is anywhere near the heating source. I am hoping they take care of it. Preferably send replacement parts and ill do it myself. I just sent him an email tonight. What do you think?