I started working on my first Howa today and I was looking for some tips or hints with these things. So far I like them, but I can see a few issues.

It uses a smaller bolt Dia. so truing the action with standard tooling wont work.

It has Metric threads, my lathe isn't set up for Metric, so thats an issue.

The barrel was into the action so freaking tight I think I busted some blood vessels trying to break the two apart. I headed it up and everything. The barrel was going back on, so I could not cut the barrel.

I do like the M-16 style extractor.

It took minimal lapping to get full contact.

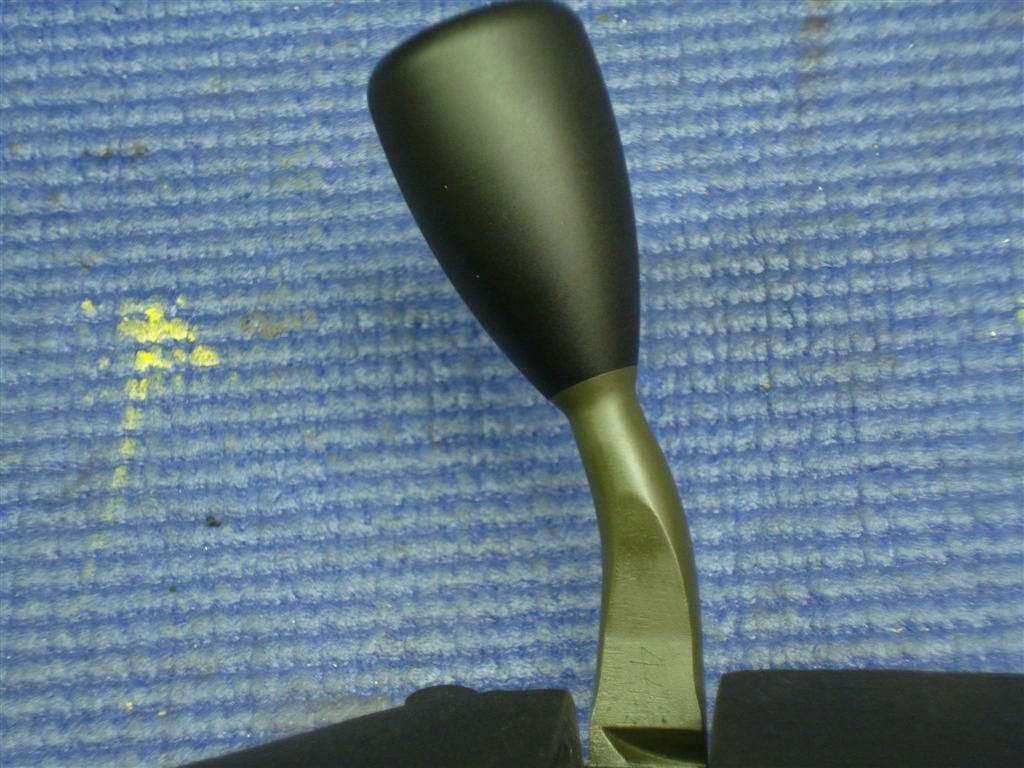

Hard bolt knob that looks great when converted.

This one had a Timney, Not sure if thats standard.

Bore looked good, nicely polished for a factory barrel.

Flat bottom, no recoil lug, easy bedding and assembly.

Rem 700 scope base setup.

Mark

It uses a smaller bolt Dia. so truing the action with standard tooling wont work.

It has Metric threads, my lathe isn't set up for Metric, so thats an issue.

The barrel was into the action so freaking tight I think I busted some blood vessels trying to break the two apart. I headed it up and everything. The barrel was going back on, so I could not cut the barrel.

I do like the M-16 style extractor.

It took minimal lapping to get full contact.

Hard bolt knob that looks great when converted.

This one had a Timney, Not sure if thats standard.

Bore looked good, nicely polished for a factory barrel.

Flat bottom, no recoil lug, easy bedding and assembly.

Rem 700 scope base setup.

Mark