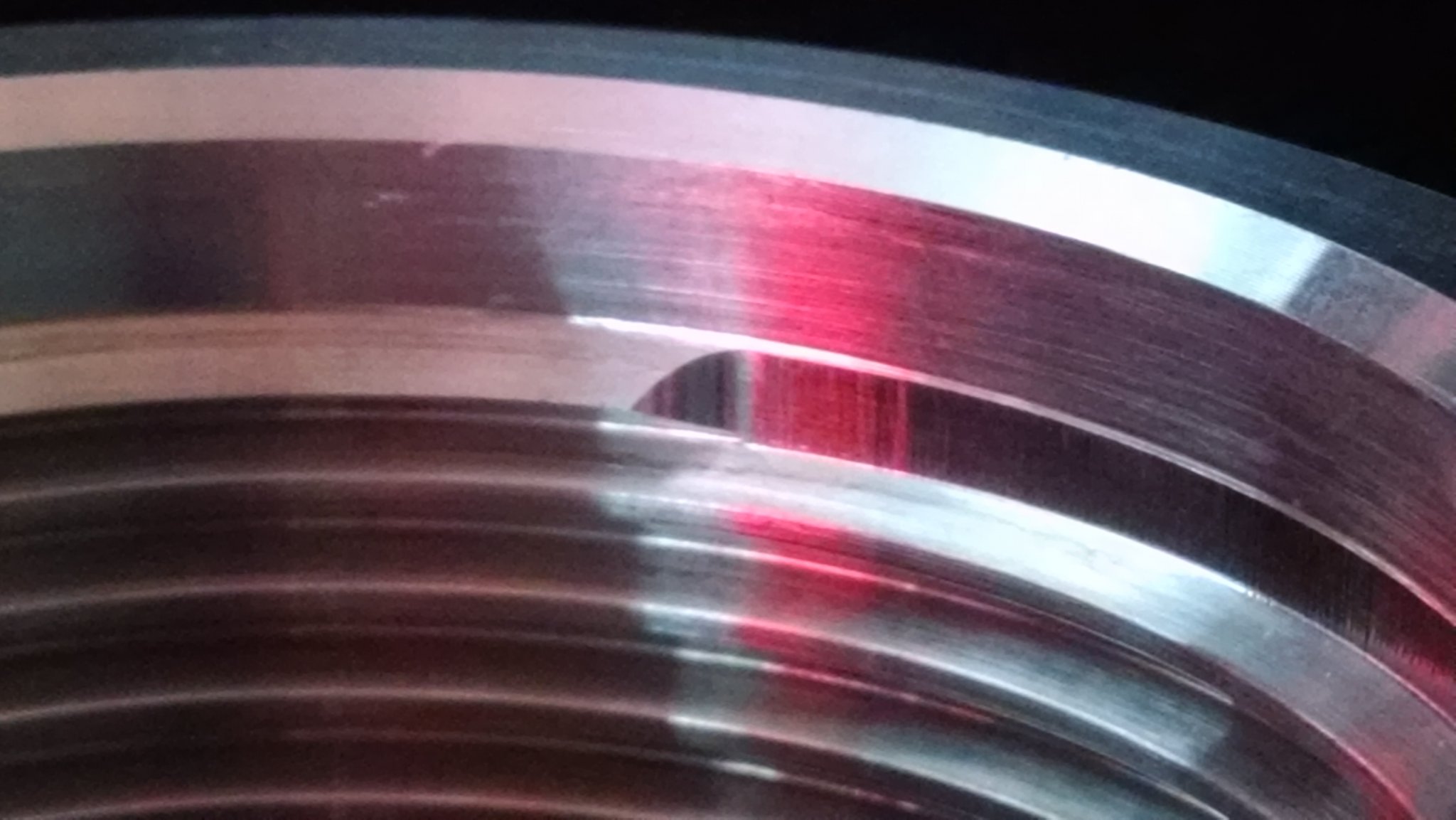

After a 7 month ordeal, that was supposed to take 10-12 weeks, I received my 6 ARC barrel from Compass Lake Engineering. Haven't put it together yet, as work stuff has kept me busy. Went to mock up my muzzle device to see how much timing it needed. Muzzle device will thread on properly and seat on the shoulder, as it has an inside relief cut before the threads start, but the peel washer that thunderbeast sent me with my muzzle device won't seat on the shoulder,as the OD of the barrel at the end of the threads is too large.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Are these threads cut properly?

- Thread starter IndianaBoy

- Start date

Did you measure the thread major diameter? If so, what is it?

The 5/8-24 major diameter maximum is .623. .498 for 1/2-28

The 5/8-24 major diameter maximum is .623. .498 for 1/2-28

.624 according to my cheap calipers. The major thread diameter isn't the problem though, its the OD just where the threads terminate before the shoulder. The muzzle device threads on fine. But a peel washer won't seat against the shoulder, and I don't see any shim kits available online that have a large enough ID to fit. I'm not a machinist but the barrel just where the threads terminate measures roughly .645.Did you measure the thread major diameter?

Last edited:

That sucks when you have a barrel like that. I’ve had them. Ended up just threading a 3 prong or leaving the brake untimed and running with it since it’s suppressed anyways. I then had my local smith turn it down

I’m sure you can find someone to turn that down. Usually guys will see threads like this and help a fellow member out. Not so much that’s it’s hard to get it done. It’s just hard to get it done and not have to wait another 6 months for it

I’m sure you can find someone to turn that down. Usually guys will see threads like this and help a fellow member out. Not so much that’s it’s hard to get it done. It’s just hard to get it done and not have to wait another 6 months for it

I'm considering just buying an assortment of 3/4 ID shim stock McMaster-Carr in various thicknesses.

This barrel certainly isn't what I paid for.

This barrel certainly isn't what I paid for.

It does indeed. Especially since this is a Bartlein blank that was turned by a smith who, when I ordered it, had a stellar reputation.That sucks when you have a barrel like that. I’ve had them. Ended up just threading a 3 prong or leaving the brake untimed and running with it since it’s suppressed anyways. I then had my local smith turn it down

Looks like I have the finest $860 tomato stake around!

ETA:

I realize this can be fixed. But after a 7 month wait from a smith who closed their doors to the public a few months after I placed my order,my only recourse is to pay another smith to fix it.

Beyond frustrating.

I'm considering getting some slightly oversized (ID) shims from McMaster-Carr. Non-deal but it might work. Looks like 18mm might be the closest I can get, since 5/8 clearly won't work.

ETA:

I realize this can be fixed. But after a 7 month wait from a smith who closed their doors to the public a few months after I placed my order,my only recourse is to pay another smith to fix it.

Beyond frustrating.

I'm considering getting some slightly oversized (ID) shims from McMaster-Carr. Non-deal but it might work. Looks like 18mm might be the closest I can get, since 5/8 clearly won't work.

Last edited:

Why can’t you send it out to be fixed? Possibly call smith to see if he fucked up an is willing to fix his errors

That thread work does not look good. That was threaded with no chamfer at the front and no relief cut at the shoulder.

Are they as least cut with accurate perpendicularity?

If they are good, just have some one cut a little more thread relief like what msgriff posted.

Depending on how oversize the area is, a crush washer may stretch over it. You could try, but use very little force(torque).

Are they as least cut with accurate perpendicularity?

If they are good, just have some one cut a little more thread relief like what msgriff posted.

Depending on how oversize the area is, a crush washer may stretch over it. You could try, but use very little force(torque).

For sure it can be fixed. Compass Lake had this barrel for 7 months after quoting me 10-12 weeks lead time. There's no fucking way I'm sending it back to them even if they offered to fix it for free.Why can’t you send it out to be fixed? Possibly call smith to see if he fucked up an is willing to fix his errors

As someone that threads hundreds, if not thousands, of barrels a year on a CNC lathe, that looks completely normal.

Personally I think not using a thread relief is better than having one for the simple reason of the washers not floating around on the smaller diameter of the relief. On the contrary, there are people that think thread reliefs are necessary, but there are often folks that thread on a manual lathe or are just regurgitating what they read on the internet.

Personally I think not using a thread relief is better than having one for the simple reason of the washers not floating around on the smaller diameter of the relief. On the contrary, there are people that think thread reliefs are necessary, but there are often folks that thread on a manual lathe or are just regurgitating what they read on the internet.

The threads appear to be perfectly concentric, the thunderbeast muzzle device bottoms out on the shoulder perfectly square.That thread work does not look good.

Are they as least cut with accurate perpendicularity?

If they are good, just have some one cut a little more thread relief like what msgriff posted.

Depending on how oversize the area is, a crush washer may stretch over it. You could try, but use very little force(torque).

Crush washer is not an option with a silencer.

Then contact LRI , GA Precision or name any smith to have them fix it. I know about paying for work that is done incorrectly or half assed or a little bit of both. It sucks.For sure it can be fixed. Compass Lake had this barrel for 7 months after quoting me 10-12 weeks lead time. There's no fucking way I'm sending it back to them even if they offered to fix it for free.

I can recommend LRI for quick turnaround. I had two barrels threaded in back in under two weeks.

If a shim was able to nest square against the shoulder, I would agree with you. How would you propose I time a muzzle device for use with a silencer when the OD just in front of the shoulder is too large to accomodate a 5/8 shim?As someone that threads hundreds, if not thousands, of barrels a year on a CNC lathe, that looks completely normal.

Personally I think not using a thread relief is better than having one for the simple reason of the washers not floating around on the smaller diameter of the relief. On the contrary, there are people that think thread reliefs are necessary, but there are often folks that thread on a manual lathe or are just regurgitating what they read on the internet.

So you machine larger than the major at the shoulder?As someone that threads hundreds, if not thousands, of barrels a year on a CNC lathe, that looks completely normal.

Personally I think not using a thread relief is better than having one for the simple reason of the washers not floating around on the smaller diameter of the relief. On the contrary, there are people that think thread reliefs are necessary, but there are often folks that thread on a manual lathe or are just regurgitating what they read on the internet.

Looks like that's going to be the route I take.Then contact LRI , GA Precision or name any smith to have them fix it. I know about paying for work that is done incorrectly or half assed or a little bit of both. It sucks.

I can recommend LRI for quick turnaround. I had two barrels threaded in back in under two weeks.

If a shim was able to nest square against the shoulder, I would agree with you. How would you propose I time a muzzle device for use with a silencer when the OD just in front of the shoulder is too large to accommodate a 5/8 shim?

Shim kits like those from Surefire or using a Precision Armament Accuwasher have a slight chamfer on the breach side of the shim to overcome this.

This.As someone that threads hundreds, if not thousands, of barrels a year on a CNC lathe, that looks completely normal.

Personally I think not using a thread relief is better than having one for the simple reason of the washers not floating around on the smaller diameter of the relief. On the contrary, there are people that think thread reliefs are necessary, but there are often folks that thread on a manual lathe or are just regurgitating what they read on the internet.

All the CNC muzzle threading programs I have used turned the muzzle down to the major OD desired, then face the shoulder. Then the threads are cut, usually to .050 from the shoulder.

Undercut thread relief grooves are usually cut on manual machines, so the operator can retract the tool without hitting the shoulder.

That said, the finish on those threads looks crappy.

Last edited:

Unfortunately, you need to specify your expectations with gunsmiths these days, or ask what their normal procedures are. There is at least one well known gunsmith, who has quite the internet following, who will use and and try to justify their use of crush washers on suppressor mounts.

Yeah. I don't think the tooling was exactly fresh, and the end wasn't dressed at all.That said, the finish on those threads looks crappy.

On a positive note, the crown look good.

There is a well respect PRS rifle builder I know a couple hours away. Looks like a road trip is in my future.

The threads appear to be perfectly concentric, the thunderbeast muzzle device bottoms out on the shoulder perfectly square.

Crush washer is not an option with a silencer.

That's correct, I think I just misread.

I have used other shims with my SR mounts successfully, such as surefire. They have a kit that's $12 and it includes a thicker spacer like what unclemoak mentioned.

Last edited:

You guys can flame me, have at it.

Before I'd wait that long I'd get a new file and remove the excess metal and drive on down the road. Uncertain times to let this get away, again.

Maybe a round file would give the relief like the photo above.

Before I'd wait that long I'd get a new file and remove the excess metal and drive on down the road. Uncertain times to let this get away, again.

Maybe a round file would give the relief like the photo above.

Oh heck…help me out here guys but isn’t cutting that relief something pretty much any smith can do in a jiffy?

And not to take away from the OP dissatisfaction with CLE. But, maybe just get it done and move on?

And not to take away from the OP dissatisfaction with CLE. But, maybe just get it done and move on?

likely the whole tenon was cut slightly oversized (.001), and the actual threads were hit with an abrasive to debur, which resulted in a C-hair smaller diameter there. Just because tbacs shims are right on the tolerance for the thread, doesn't mean that everyone else's shims will be.Yeah. I don't think the tooling was exactly fresh, and the end wasn't dressed at all.

On a positive note, the crown look good.

There is a well respect PRS rifle builder I know a couple hours away. Looks like a road trip is in my future.

Try some other shims before you pay to have it cut.

Unfortunately, you need to specify your expectations with gunsmiths these days, or ask what their normal procedures are. There is at least one well known gunsmith, who has quite the internet following, who will use and and try to justify their use of crush washers on suppressor mounts.

In their defense, there are some, but very few applications where crush washers are acceptable and have been for 30+ years, namely the Ops Inc / Allen Engineering line of suppressors.

Those threads do not look great.

The undercut is easier to program for a cnc than it is to do manually. Both ways are easy.

The undercut is easier to program for a cnc than it is to do manually. Both ways are easy.

Frankly those threads don't look well done. The peaks of the major OD are flat and OP is measuring the major .001" over. Never mind no relief or chamfer. It's easily fixed but is poor workmanship.

Last edited:

This one is $9, providing you are threaded 5/8-24 it will be what would work.

I agree the threads don't look the best. Should be fixed.

There is another way to fix it (discounting timing issues). Higbee the first thread or so of the muzzle device. Internet pic.

The counterbore below isn't needed for your application. I cut it using a nakanishi air grinder (expensive high rpm air dremel) with a carbide burr. Wanted to change my black ball with a titanium one. Matches shroud and rail now.

There is another way to fix it (discounting timing issues). Higbee the first thread or so of the muzzle device. Internet pic.

The counterbore below isn't needed for your application. I cut it using a nakanishi air grinder (expensive high rpm air dremel) with a carbide burr. Wanted to change my black ball with a titanium one. Matches shroud and rail now.

The undercut thread on one of my barrels made the washer not center and wobble around, and also when the washer gets crushed inside that undercut it wont come off, kind of a pain to get it off, need vice grips, have to be careful not to destroy the threads. If the washer dont fit over it carefully file or sand the inside of the washer till it fits, maybe dremel. If you screw it up its a $3. washer.... try again. I'd rather have it like your picture than the undercut way.

Similar threads

- Replies

- 11

- Views

- 541

- Replies

- 5

- Views

- 648

- Replies

- 9

- Views

- 532