Back story, bought a cheap 1.5 mk2 last year. Really liked it but wished it was a folder for packing and cleaning purposes. I'd asked and saw a few others ask about using the ax or used at folder buttstocks on older aics/ae. I finally decided to find out.

I bought a lightly used at folder buttstock from a member here who wanted to upgrade. Perfect, we're both happy now. The ae and older aics use epoxy and dowel pins to hold buttstock to center section of chassis, the ax/at uses epoxy and countersunk screws. Obviously the screws dont have anything to thread into on older stocks. Itd be cool if I had the machining skills to make a threaded pin insert that those screws could thread into....but I dont.

Everything lines up, dowel pins are .239" diameter, bottom of countersink hole is .233 and top is bigger. I reamed countersunk hole to .238, nice press fit for pins, but they arent fully supported in the female folder extension. I ended up drilling and tapping 10-32 holes, 1/4" deep, at 3 & 9 oclock. Those combined with pins and epoxy should be as solid as a factory ae folder.

The male folder retaining stud was a bit more challenging. The metric screw (from an at), has a button head that needs to be countersunk inside trigger inlet area. I located hole for screw and drilled a .198" hole there and all the way through the other side. That button head measures .350 across. I went from right to left with a .344" pilot bit, using the .198" hole. I drilled just deep enough for top of button head to be flush with trigger inlet. Broke out the devcon and blue loctite and got everything assembled.

Hole for male retainer stud and 10-32 drilled

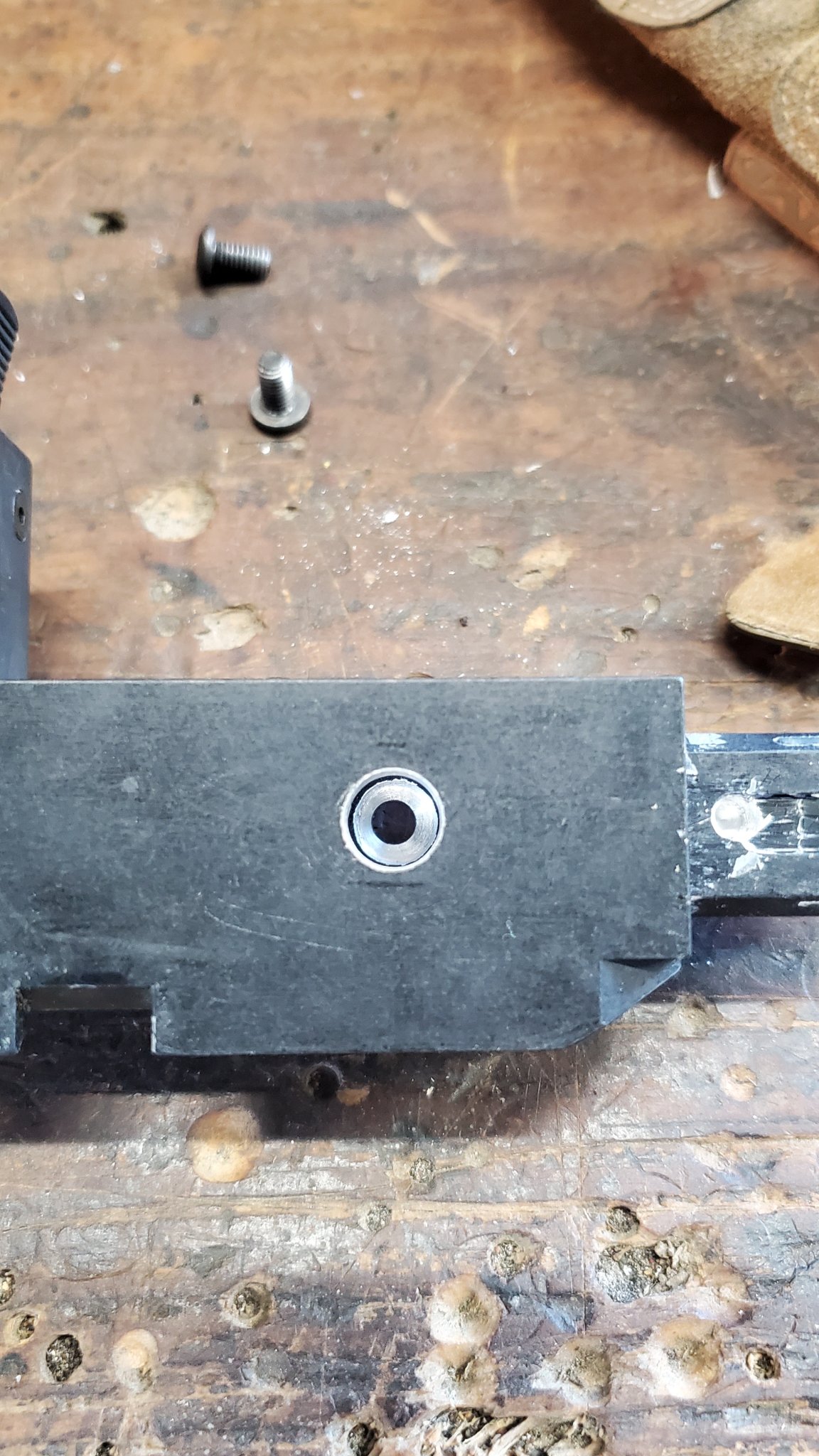

.344 hole on right side and recessed hole for retaining stud buttonhead(visible through hole)

I had some extra epoxy mixed, so I filled in the countersunk hole around dowel pin. Probably not needed, but doesnt hurt.

Definitely not as easy as an at to ax buttstock swap, but its doable. I think I had right at 1.5-2 hrs in it, the drill press with an x-y table is almost required. I looked at my mk3 folder last night, to see how AI does the male retaining stud. Ae's have a metric thread hole on the left side, with metric stud that retaining stud screws onto. I'm in the boonies so finding a .4" long tiny metric stud and tap wouldn't be handy. If I was doing it over, I'd probably do it that way just because it's more factory. Honestly when putting an at butt on an ae, "like factory" kinda goes out the window.

I bought a lightly used at folder buttstock from a member here who wanted to upgrade. Perfect, we're both happy now. The ae and older aics use epoxy and dowel pins to hold buttstock to center section of chassis, the ax/at uses epoxy and countersunk screws. Obviously the screws dont have anything to thread into on older stocks. Itd be cool if I had the machining skills to make a threaded pin insert that those screws could thread into....but I dont.

Everything lines up, dowel pins are .239" diameter, bottom of countersink hole is .233 and top is bigger. I reamed countersunk hole to .238, nice press fit for pins, but they arent fully supported in the female folder extension. I ended up drilling and tapping 10-32 holes, 1/4" deep, at 3 & 9 oclock. Those combined with pins and epoxy should be as solid as a factory ae folder.

The male folder retaining stud was a bit more challenging. The metric screw (from an at), has a button head that needs to be countersunk inside trigger inlet area. I located hole for screw and drilled a .198" hole there and all the way through the other side. That button head measures .350 across. I went from right to left with a .344" pilot bit, using the .198" hole. I drilled just deep enough for top of button head to be flush with trigger inlet. Broke out the devcon and blue loctite and got everything assembled.

Hole for male retainer stud and 10-32 drilled

.344 hole on right side and recessed hole for retaining stud buttonhead(visible through hole)

I had some extra epoxy mixed, so I filled in the countersunk hole around dowel pin. Probably not needed, but doesnt hurt.

Definitely not as easy as an at to ax buttstock swap, but its doable. I think I had right at 1.5-2 hrs in it, the drill press with an x-y table is almost required. I looked at my mk3 folder last night, to see how AI does the male retaining stud. Ae's have a metric thread hole on the left side, with metric stud that retaining stud screws onto. I'm in the boonies so finding a .4" long tiny metric stud and tap wouldn't be handy. If I was doing it over, I'd probably do it that way just because it's more factory. Honestly when putting an at butt on an ae, "like factory" kinda goes out the window.

Last edited: