I'm currently chatting with MK Machining to see if what an ideal powder pan dimension for the Autotrickler/Autothrow would be. It would be more affordable than the billet aluminum pans on the market. Ideally I would like a 1.5" to 2" tall pan and the 1.125" base to me is acceptable. All they would need to do is print a taller version of their Chargemaster pan. Would you prefer a taller/shorter pan? Wider base?

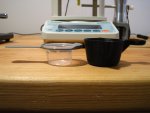

The dimensions of their RCBS Antistatic powder pan is 1.125" base and 0.85" tall. The sauce cup/handle that came with my autotrickler is 1.22" base and 0.90" tall.

I appreciate any insight.

The dimensions of their RCBS Antistatic powder pan is 1.125" base and 0.85" tall. The sauce cup/handle that came with my autotrickler is 1.22" base and 0.90" tall.

I appreciate any insight.