Reading through a certain thread on here, a lot of folks including myself seem to want AW mags that would be compatible for a 223 cartridge. Why hasn’t anyone with a 3D printer prototyped something like that as there seems to be a lot of interest in something like that.

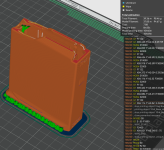

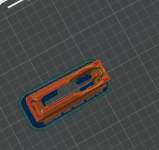

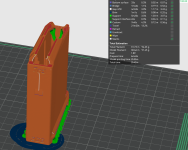

Would it be easier to develop an insert for an existing AW mag body similar to what MDT does for their 223mags? A whole unibody, printed magazine? I know @Tyler Kemp is the print god. Maybe he could do something like that?

Thinking out loud here as it would be cool to have that option as AICS mags are lame.

Would it be easier to develop an insert for an existing AW mag body similar to what MDT does for their 223mags? A whole unibody, printed magazine? I know @Tyler Kemp is the print god. Maybe he could do something like that?

Thinking out loud here as it would be cool to have that option as AICS mags are lame.