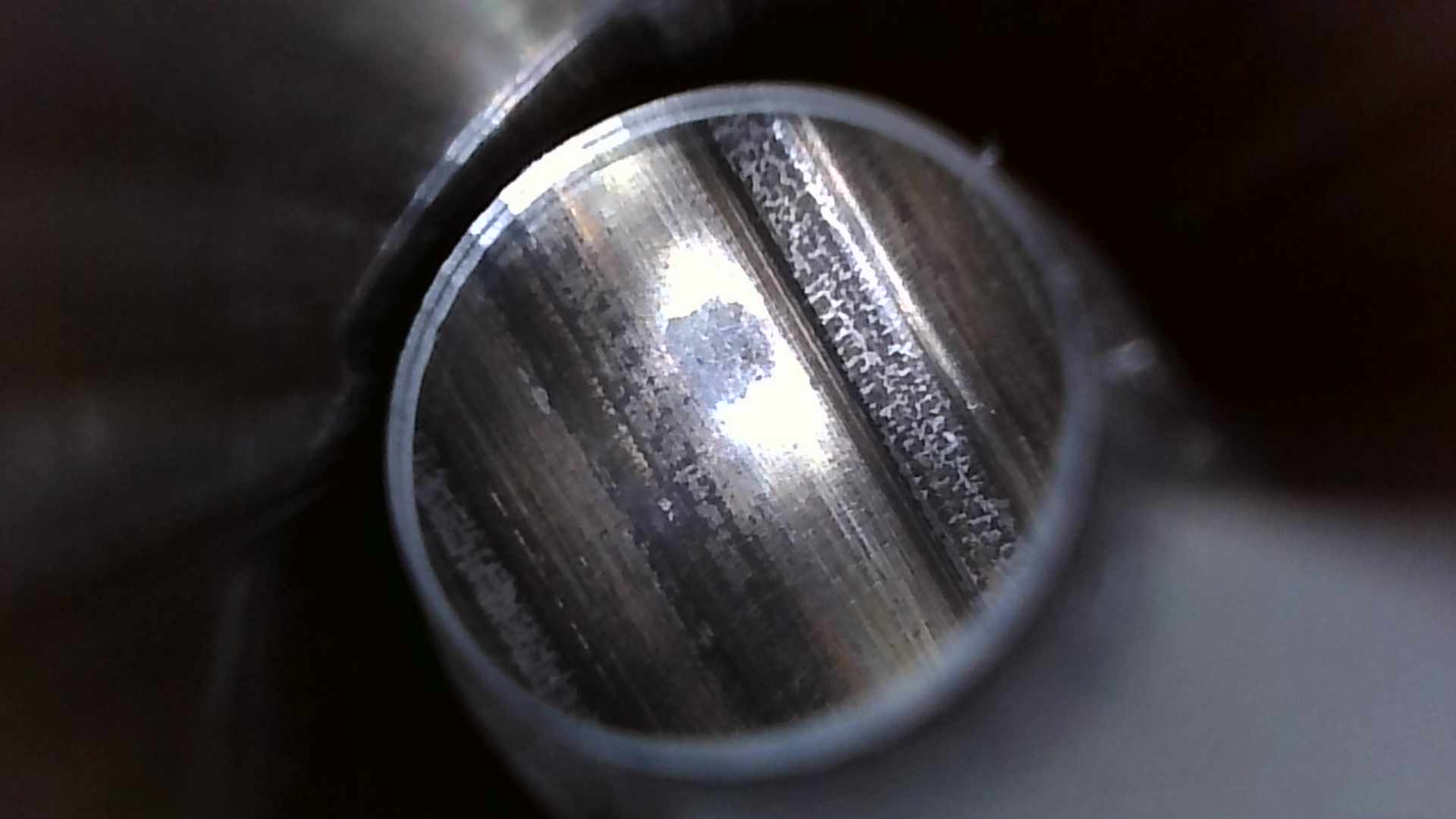

Hi all, I have a Seekins Havak Hit in 6.5 cm and am cleaning it thoroughly for the first time. I have put about 380 rounds through the barrel and can't get the sucker clean. Under the borescope I found these weird "spots or patches". What are they and should I be concerned? Almost looks like a thin layer of metal/carbon/copper flaked off. There are many of these spots through the barrel. Everything I use should be pretty easy on the barrel. The brushes are nickel coated, with nylon bristles and a carbon fiber cleaning rod. Help.

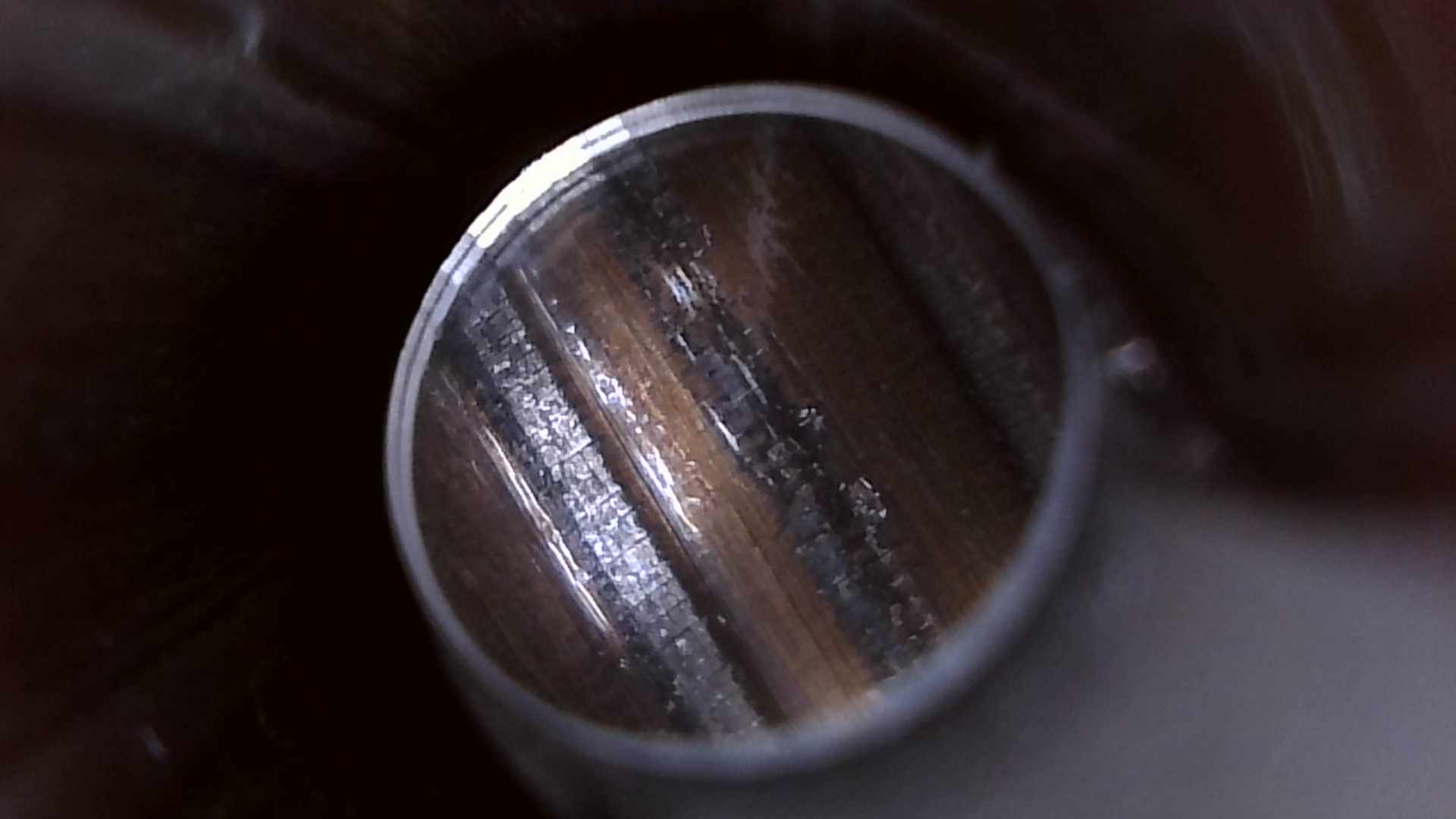

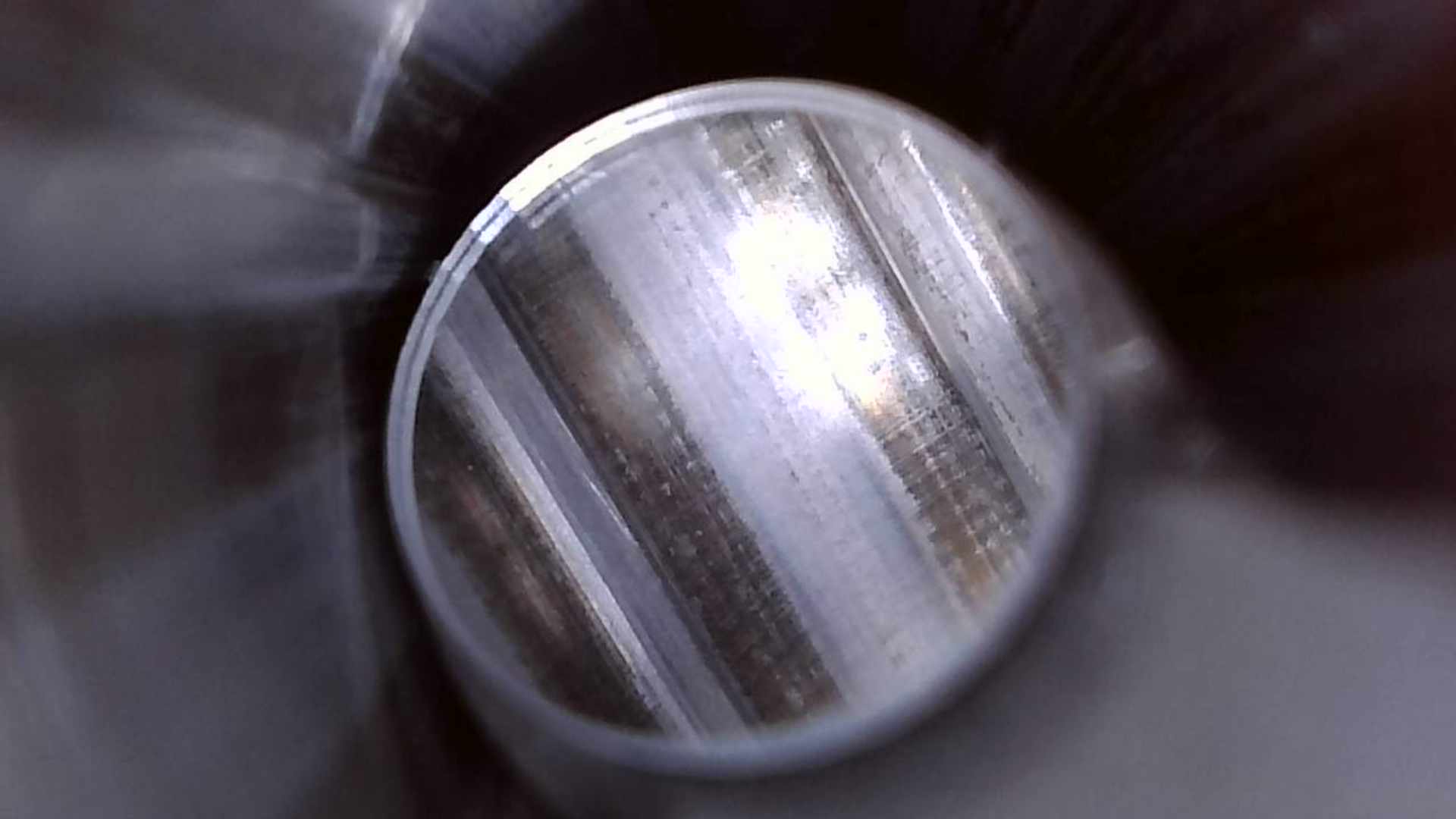

Additionally I can't get the damn barrel clean. I have Boretech Eliminator with nylon brushes and some patches. I have spend probably two days with 40-50 patches. The 10 inches on the end are fairly clean but the first 10 or so look untouched. I have let it soak overnight, targeted brushing in the first half etc. I'm still getting pretty dirty patches so its got to be working but I didn't think it would take this much. Here's the first half and second half for comparison:

Additionally I can't get the damn barrel clean. I have Boretech Eliminator with nylon brushes and some patches. I have spend probably two days with 40-50 patches. The 10 inches on the end are fairly clean but the first 10 or so look untouched. I have let it soak overnight, targeted brushing in the first half etc. I'm still getting pretty dirty patches so its got to be working but I didn't think it would take this much. Here's the first half and second half for comparison: