I make these little buggers as a sort of "kindness offering" to gunsmiths. The cast ones have an expiration date as the material stretches around the square tubing over time, cracks, and then launches a barrel across the shop floor as it's being polished against a square wheel grinder/belt sander.

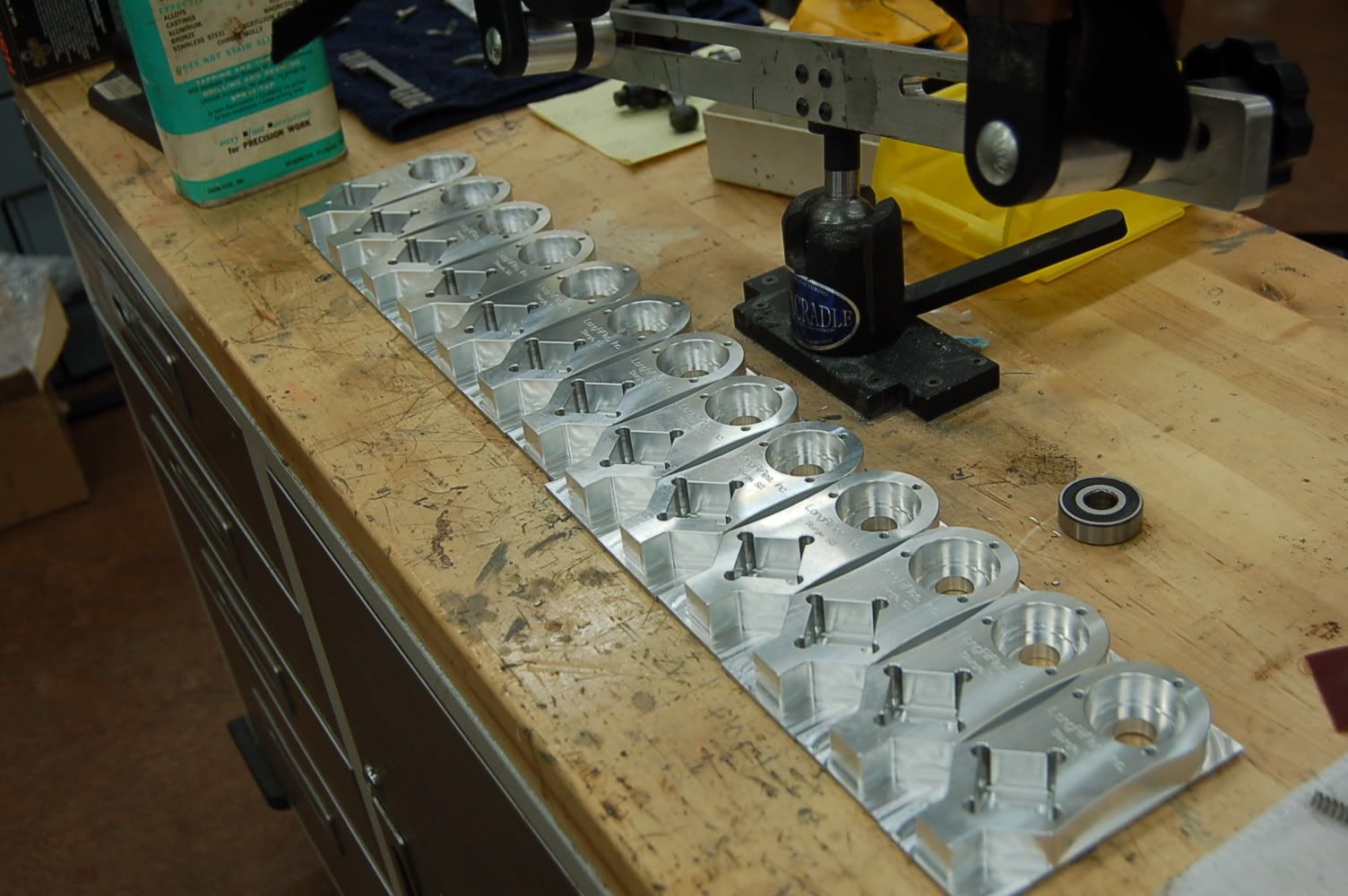

Mine are 100% cnc machined from bar stock with little ergonomic features. Fully profiled and every corner has a 1/16th radius to save the hands from nicks n cuts.

Sold a bunch here lately so I need to build the pile back up.

Nothing fancy, just kinda' neat lookin.

The only thing cooler than the sound a 3/8 3F high helix carb EM makes as it shreds through aluminum at 100ipm is one that can do it at 300imp. Unfortunately my ol girl just won't go that fast.

Enjoy,

C

Mine are 100% cnc machined from bar stock with little ergonomic features. Fully profiled and every corner has a 1/16th radius to save the hands from nicks n cuts.

Sold a bunch here lately so I need to build the pile back up.

Nothing fancy, just kinda' neat lookin.

The only thing cooler than the sound a 3/8 3F high helix carb EM makes as it shreds through aluminum at 100ipm is one that can do it at 300imp. Unfortunately my ol girl just won't go that fast.

Enjoy,

C