Recently got an 21st century barrel vise, when I tried to take off the barrel from a custom R700 clone action, I found the torque wrench reaches to the maximum torque(100f/lb) easily and the barrel becomes slipping within the vise when I use things like thick paper board pieces and dry wall tape to avoid direct contact between the barrel and the vise. Even I have tighten the 4 nuts on top pretty hard, it still does that.

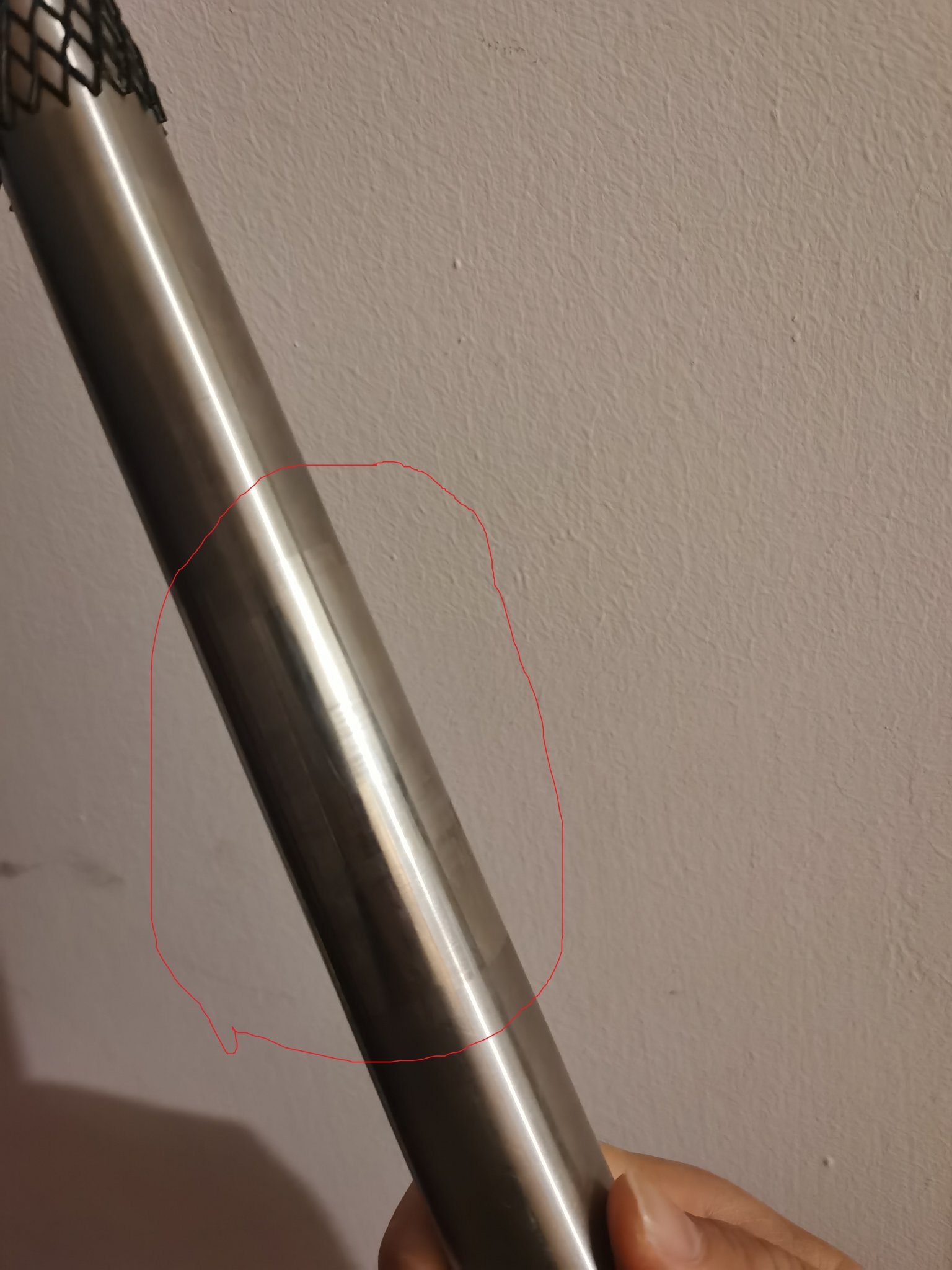

The only way I can take off the barrel is to let it have metal to metal contact between the barrel and vise. Once the barrel is off, I can see there is some marks on the surface. Not sure if it could cause any issue to the barrel? And is getting a pair of bushing for the vise the last option I have if I don't want to leave marks like that?

I torque the barrel using torque wrench to 70f/lb.

Thank you.

The only way I can take off the barrel is to let it have metal to metal contact between the barrel and vise. Once the barrel is off, I can see there is some marks on the surface. Not sure if it could cause any issue to the barrel? And is getting a pair of bushing for the vise the last option I have if I don't want to leave marks like that?

I torque the barrel using torque wrench to 70f/lb.

Thank you.