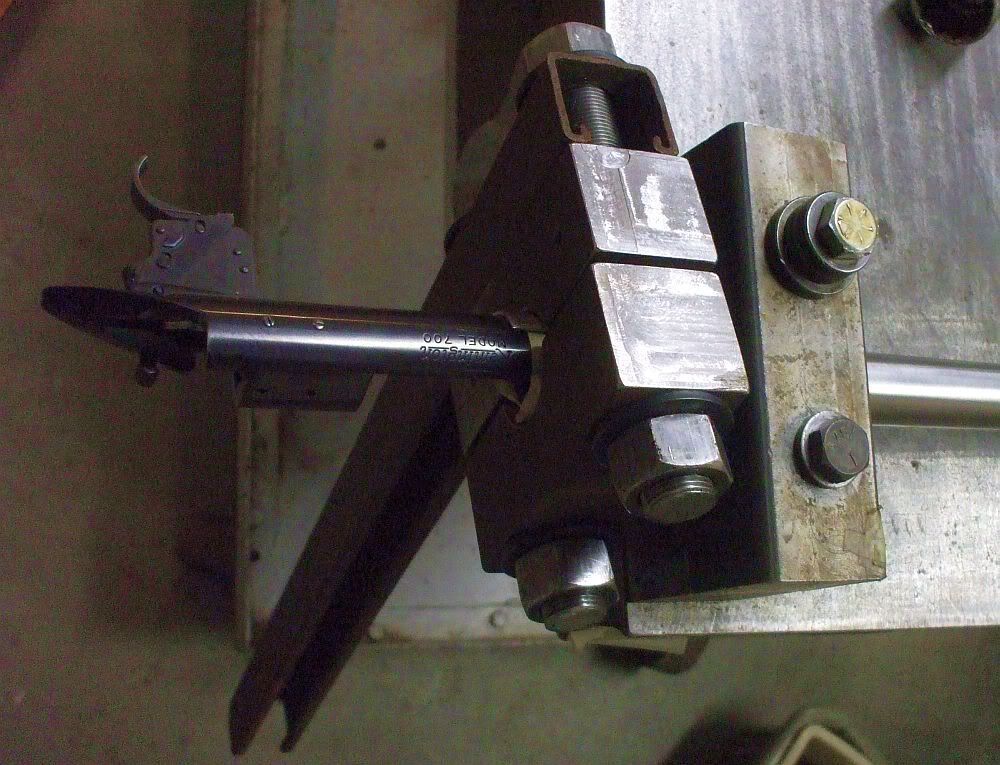

Re: Barrel Vise

There are lots of ways to make action wrenches and barrel vises. Randy Ketchum has a hydraulic jack in the barrel vise he made and mounted on his bench.

I prefer to make the wrenches and vises from 2"x 2" steel that I get from the scrap yard.

I prefer to make the collets from 1.5" round 6061 Aluminum rod that I get in 8' lengths from J&L.

Sometimes I make the collets with a single slit all the way. Sometimes a two piece with two slits all the way. And sometimes with opposing partial slits.

I make the inside diameter of the collet with a boring bar on the lathe. Sometimes I make a taper on the inside diameter to match the taper of the barrel.

10 years ago I used rosin from Brownells. Now I am using powdered sugar, and it works better. My wife tells me corn starch would work better still, but I have not tested it.

An important part is the bench. I got a 400 pound elevating bench with 3/8" plate steel from Boeing surplus. It rolls and the wheels lock. I have broken a few 1/2-13 hardened bolts in this system, but I am converting to 7/8-14.

The action wrenches for a flat bottomed receiver will never break a bolt. It is the barrel vises that get tightened until slippage stops that break bolts. At 500 foot pounds of torque to get off old military barrels rusted on, lots of friction is needed on the barrel. I tighten the barrel vise with a 3' long socket wrench using both hands and both feet. Round bottomed receiver action wrenches look like another barrel vise, with Aluminum collet or brass shims.

The trick is getting the barrel on or off without scuffing up the bluing. I like to clean the barrel and collet interface with alcohol and then dry it and then apply the powdered sugar.