From a preparedness perspective, I’m looking for an armorers parts kit, or replacement parts kit for my ARs. Who makes the best one? If it’s a better deal just to part it out, I can do that instead.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Best replacement parts kit

- Thread starter WoobieJ

- Start date

At my bench I have an organizer box that holds spare AR15 parts and accessories. There's a bunch of stuff in it but the highlights are the following:

-Aero Precision field repair kit

-Crush washers

-Muzzle device shims

-End plate

-A2 flash hider

-Firing pin

-Firing pin retaining pin

-Cam pin

-Spare bolt

-Gas rings

-Mil-spec trigger group

-Safety lever

-Charging handle

The above stuff will run about $150 if you go with Aero Precision or CMMG mostly. Also in the box are a set of BUIS, different grips, rails, rail covers, an action spring, etc... This is in addition to a couple spare barrels, a spare upper, and a couple back up guns.

-Aero Precision field repair kit

-Crush washers

-Muzzle device shims

-End plate

-A2 flash hider

-Firing pin

-Firing pin retaining pin

-Cam pin

-Spare bolt

-Gas rings

-Mil-spec trigger group

-Safety lever

-Charging handle

The above stuff will run about $150 if you go with Aero Precision or CMMG mostly. Also in the box are a set of BUIS, different grips, rails, rail covers, an action spring, etc... This is in addition to a couple spare barrels, a spare upper, and a couple back up guns.

Good list. A lot of this you’ll gather after building out a few rifles, swapping components here and there, etc.At my bench I have an organizer box that holds spare AR15 parts and accessories. There's a bunch of stuff in it but the highlights are the following:

-Aero Precision field repair kit

-Crush washers

-Muzzle device shims

-End plate

-A2 flash hider

-Firing pin

-Firing pin retaining pin

-Cam pin

-Spare bolt

-Gas rings

-Mil-spec trigger group

-Safety lever

-Charging handle

The above stuff will run about $150 if you go with Aero Precision or CMMG mostly. Also in the box are a set of BUIS, different grips, rails, rail covers, an action spring, etc... This is in addition to a couple spare barrels, a spare upper, and a couple back up guns.

At minimum I’d keep a whole BCG, charging handle, spare LPK, gas tube roll pins, and 2-3 sets of springs.

Also, get a good reaction rod, a gas block/gas tube jig, and a shaped 2x4 or something as a receiver block. Also an inch/lb, a ft/lb torque wrench, and a standard AR armorers wrench. Keep some blue locktite handy, some rockset, and some antiseize. And get a solid vice mounted to a sturdy table. A heat gun in also valuable and a necessity with some barrel/upper receiver instals.

My list should cost you about $400 (a good BCG is $150-$200), tools included.

Bolts from competent manufacturers

Extractors

Extractor springs with inserts

Cam pin

Ejector spring/selector detent spring (same part, every standard AR-15 has 2 inside)

TDP Firing pin (checked for protrusion spec)

Firing Pin Retaining Pins

TDP gas rings, not imported trash

You can also just have spare BCGs that are east to plug-and-play.

Bolt disassembly tool or use the spent case method with a vice. Bolt disassembly tool is really small and light though.

Spare action/recoil springs of correct material and length per the TDP

Lower Parts Kits

Spare Fire Control Groups

Carrier Key and fasteners

Rockset

Red Loc-tite

Spare gas tubes and roll pins

Gas block small parts for your specific gas block, whether taper pins, set screws, pins, or fasteners

Spares for your specific optics and aiming devices, such as batteries, ring fasteners, caps

Tools to replace as much as you can from above.

If you’re in an extreme cold climate, consider having a spare pistol grip if you went with an after-market option. I broke a 1st Gen MIAD in Finland doing CQM drills, suppressed, in -30˚C, 3-day course shooting high volume. That grip just cracked in about every way it could. Real A2 grips never did that on me. Magpul changed the design to use a flat screw instead of the original conical screw, but the little tabs that hold the backstop and grip core in place completely fragmented, in addition to the grip itself splitting. I had a spare grip in my rifle case in the range building/barracks where we were staying, so I was able to replace it and continue training.

Build a compact kit in a Plano case you can have in one location that’s easy to grab and pack.

Extractors

Extractor springs with inserts

Cam pin

Ejector spring/selector detent spring (same part, every standard AR-15 has 2 inside)

TDP Firing pin (checked for protrusion spec)

Firing Pin Retaining Pins

TDP gas rings, not imported trash

You can also just have spare BCGs that are east to plug-and-play.

Bolt disassembly tool or use the spent case method with a vice. Bolt disassembly tool is really small and light though.

Spare action/recoil springs of correct material and length per the TDP

Lower Parts Kits

Spare Fire Control Groups

Carrier Key and fasteners

Rockset

Red Loc-tite

Spare gas tubes and roll pins

Gas block small parts for your specific gas block, whether taper pins, set screws, pins, or fasteners

Spares for your specific optics and aiming devices, such as batteries, ring fasteners, caps

Tools to replace as much as you can from above.

If you’re in an extreme cold climate, consider having a spare pistol grip if you went with an after-market option. I broke a 1st Gen MIAD in Finland doing CQM drills, suppressed, in -30˚C, 3-day course shooting high volume. That grip just cracked in about every way it could. Real A2 grips never did that on me. Magpul changed the design to use a flat screw instead of the original conical screw, but the little tabs that hold the backstop and grip core in place completely fragmented, in addition to the grip itself splitting. I had a spare grip in my rifle case in the range building/barracks where we were staying, so I was able to replace it and continue training.

Build a compact kit in a Plano case you can have in one location that’s easy to grab and pack.

I use these Plano cases for storing spares and tools.

Amazon product ASIN B001447AW2

Most AR stuff is pretty small so you could probably pack one out with tools and parts pretty easily.

Amazon product ASIN B001447AW2

Most AR stuff is pretty small so you could probably pack one out with tools and parts pretty easily.

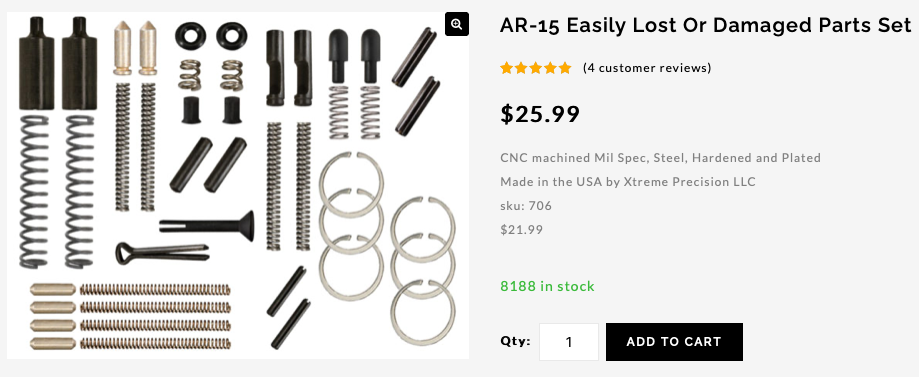

I've found Xtreme Precision to be a good source for AR-15 and AR-10 parts and tools. No bolts, bolt carriers or gas blocks.

They are a manufacturer located in Los Angeles, CA.

Here's one of their many kits. You can also by the individual parts separately.

AR-15 Easily Lost Or Damaged Parts Set

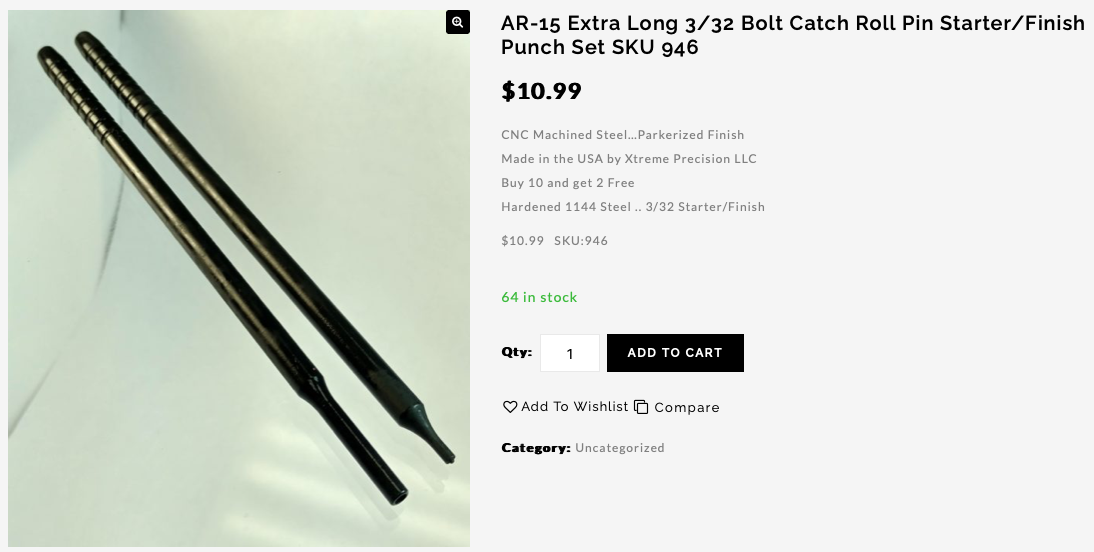

Don't forget to have some good punches as well. These are nice for dealing with the bolt catch roll pin.

AR-15 Extra Long 3/32 Bolt Catch Roll Pin Starter/Finish Punch Set

They are a manufacturer located in Los Angeles, CA.

Here's one of their many kits. You can also by the individual parts separately.

AR-15 Easily Lost Or Damaged Parts Set

Don't forget to have some good punches as well. These are nice for dealing with the bolt catch roll pin.

AR-15 Extra Long 3/32 Bolt Catch Roll Pin Starter/Finish Punch Set

Made that mistake once. If something looks suspiciously cheap, there's a reason.TDP gas rings, not imported trash

@WoobieJ this is a post you should pay attention to, from a source you should absorb all the knowledge you can from.Bolts from competent manufacturers

Extractors

Extractor springs with inserts

Cam pin

Ejector spring/selector detent spring (same part, every standard AR-15 has 2 inside)

TDP Firing pin (checked for protrusion spec)

Firing Pin Retaining Pins

TDP gas rings, not imported trash

You can also just have spare BCGs that are east to plug-and-play.

Bolt disassembly tool or use the spent case method with a vice. Bolt disassembly tool is really small and light though.

Spare action/recoil springs of correct material and length per the TDP

Lower Parts Kits

Spare Fire Control Groups

Carrier Key and fasteners

Rockset

Red Loc-tite

Spare gas tubes and roll pins

Gas block small parts for your specific gas block, whether taper pins, set screws, pins, or fasteners

Spares for your specific optics and aiming devices, such as batteries, ring fasteners, caps

Tools to replace as much as you can from above.

If you’re in an extreme cold climate, consider having a spare pistol grip if you went with an after-market option. I broke a 1st Gen MIAD in Finland doing CQM drills, suppressed, in -30˚C, 3-day course shooting high volume. That grip just cracked in about every way it could. Real A2 grips never did that on me. Magpul changed the design to use a flat screw instead of the original conical screw, but the little tabs that hold the backstop and grip core in place completely fragmented, in addition to the grip itself splitting. I had a spare grip in my rifle case in the range building/barracks where we were staying, so I was able to replace it and continue training.

Build a compact kit in a Plano case you can have in one location that’s easy to grab and pack.

@LRRPF52 thank you. Helped me make some modifications to my own back stash.

Sorry I didn’t read the posts above mine. It’s interesting to see almost the same recommendations.

One thing I learned the hard way was that parts are not the parts you think you need in many cases.

I’ve seen dealer parts lists for every single AR-15 part minus the lower receiver from manufacturers in either Taiwan or the Philippines, not sure which. These were on sheets that had fallen on the floor at SHOT Show a few years ago. You could a complete "AR-15” parts kit for $99. Shameless businessmen quickly jumped on those parts sources and started up companies that crank out AR-15 shaped excrement.

Cheap springs, cheap pins, bare bones small parts made to look the same, but are far from it. This is what I suspect the low-ball price point shops are doing, then sourcing US-made lowers and maybe some barrels, and slapping them together for bargain-shoppers.

Aside from the crappy barrels, you will see early parts wear on your extractor spring, ejector spring, and recoil spring with the fake parts.

A lot of those bolts will start galling and shedding material on the lugs as they shave through the extension, if the extractors don’t break first.

Action springs will compress and form uneven coil separation because they were made from chinesium with unknown heat-treating, nothing like a TDP-compliant spring.

Zinc-plated detents made from who-knows-what kind of metal will wear the finish off, and corrode on the zinc surface if you’re in a wet environment. I saw that happening real-time when I replaced the broken, fragmented pistol grip I described. The selector detent was fizzling right before my eyes, and that was in -27˚ to -30˚C temps.

I mentioned that to Bill Alexander many years ago, and he looked up the specs on the TDP and said the detents are all supposed to be cadmium-plated. I’ve seen some other parts kit manufacturers use nice stainless detents.

Most have read posts about bolt material, processes, testing, and quality. This is one area several reputable manufacturers disagree with the Mil-STD TDP specs, namely the HPT requirement, which is stupid.

If I wanted a top notch 5.56 bolt, it would be from Colt Canada/Diemaco, KAC, or that new process with the Liquid Burnishing that increases bolt life by a factor of 2 demonstrated by ARDEC. They took M4A1s to 26,000rds in those tests.

Anyone who doubts the “parts aren’t parts” argument can simply sit down and watch a few SOTAR videos to see what kind of garbage is out there, both in parts quality, dimensions, and build quality.

Even if you aren’t keeping spares, you need to replace those 3 critical springs about every 5000rds on a fairly regular high volume shoot schedule, and sooner if your shoot volume is compressed. (Extractor, Ejector, Recoil springs)

I’m also not a fan of the O-ring band-aid for the extractor, which was a short-term solution to PIP SOCOM M4A1s with the then-new heavier barrels with tight chambers, especially when shot with the KAC NT4. Those were a recipe for excess cyclic rate or FTExtract, not because of extractor spring tension, but some dimensions that got away from them with reamers and then trying to run a can on CLGS 14.5” with a standard gas port.

One thing I learned the hard way was that parts are not the parts you think you need in many cases.

I’ve seen dealer parts lists for every single AR-15 part minus the lower receiver from manufacturers in either Taiwan or the Philippines, not sure which. These were on sheets that had fallen on the floor at SHOT Show a few years ago. You could a complete "AR-15” parts kit for $99. Shameless businessmen quickly jumped on those parts sources and started up companies that crank out AR-15 shaped excrement.

Cheap springs, cheap pins, bare bones small parts made to look the same, but are far from it. This is what I suspect the low-ball price point shops are doing, then sourcing US-made lowers and maybe some barrels, and slapping them together for bargain-shoppers.

Aside from the crappy barrels, you will see early parts wear on your extractor spring, ejector spring, and recoil spring with the fake parts.

A lot of those bolts will start galling and shedding material on the lugs as they shave through the extension, if the extractors don’t break first.

Action springs will compress and form uneven coil separation because they were made from chinesium with unknown heat-treating, nothing like a TDP-compliant spring.

Zinc-plated detents made from who-knows-what kind of metal will wear the finish off, and corrode on the zinc surface if you’re in a wet environment. I saw that happening real-time when I replaced the broken, fragmented pistol grip I described. The selector detent was fizzling right before my eyes, and that was in -27˚ to -30˚C temps.

I mentioned that to Bill Alexander many years ago, and he looked up the specs on the TDP and said the detents are all supposed to be cadmium-plated. I’ve seen some other parts kit manufacturers use nice stainless detents.

Most have read posts about bolt material, processes, testing, and quality. This is one area several reputable manufacturers disagree with the Mil-STD TDP specs, namely the HPT requirement, which is stupid.

If I wanted a top notch 5.56 bolt, it would be from Colt Canada/Diemaco, KAC, or that new process with the Liquid Burnishing that increases bolt life by a factor of 2 demonstrated by ARDEC. They took M4A1s to 26,000rds in those tests.

Anyone who doubts the “parts aren’t parts” argument can simply sit down and watch a few SOTAR videos to see what kind of garbage is out there, both in parts quality, dimensions, and build quality.

Even if you aren’t keeping spares, you need to replace those 3 critical springs about every 5000rds on a fairly regular high volume shoot schedule, and sooner if your shoot volume is compressed. (Extractor, Ejector, Recoil springs)

I’m also not a fan of the O-ring band-aid for the extractor, which was a short-term solution to PIP SOCOM M4A1s with the then-new heavier barrels with tight chambers, especially when shot with the KAC NT4. Those were a recipe for excess cyclic rate or FTExtract, not because of extractor spring tension, but some dimensions that got away from them with reamers and then trying to run a can on CLGS 14.5” with a standard gas port.

Similar threads

- Replies

- 25

- Views

- 1K

- Replies

- 0

- Views

- 141