Hey Gents, just wanted to get a few ideas from some other gunsmiths out here about truing the bolt lugs and face up on a bolt action, specifically a Remington 700.

Would you agree that the idea of truing the lugs and bolt face should be done so the cuts are concentric to the outer diameter of the bolt body???

The bolt body rests in the bolt raceway via gravity, now were not talking about sleeved bolts, just factory guns. I also understand that the cocking piece and trigger connector contact pushes up the back of the bolt body.

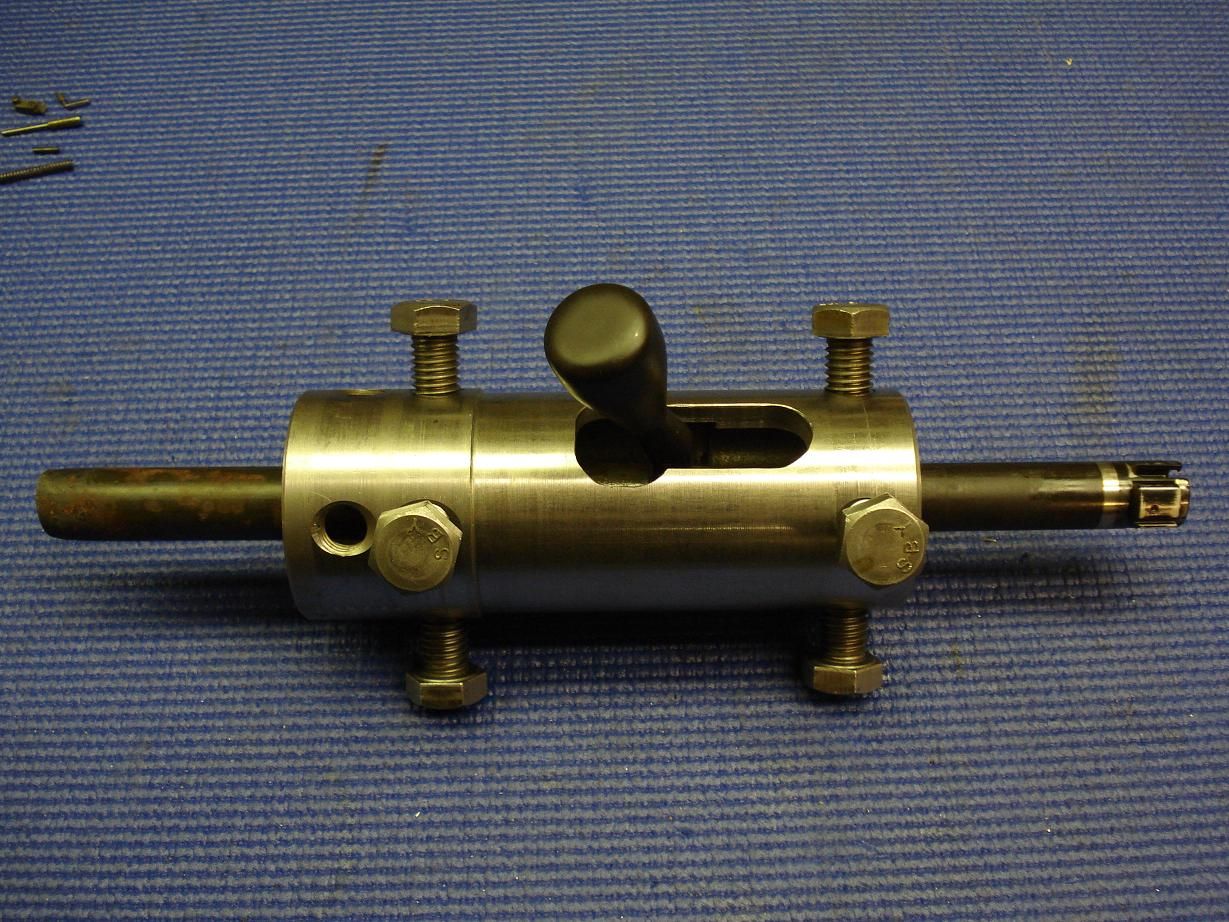

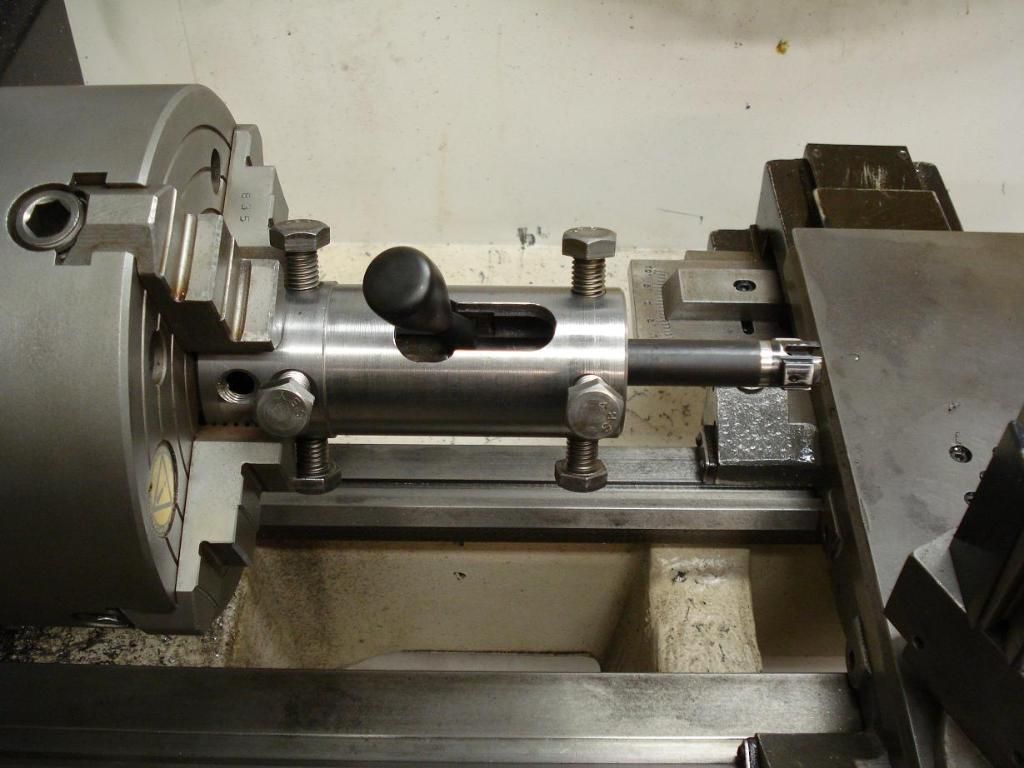

So how do you indicate your bolts in for truing? I'm familiar with a few common practices, but I just dont get that warm and fuzzy about any of them or the process of setting them up.

So if you don't mind, what do you guys do?

Would you agree that the idea of truing the lugs and bolt face should be done so the cuts are concentric to the outer diameter of the bolt body???

The bolt body rests in the bolt raceway via gravity, now were not talking about sleeved bolts, just factory guns. I also understand that the cocking piece and trigger connector contact pushes up the back of the bolt body.

So how do you indicate your bolts in for truing? I'm familiar with a few common practices, but I just dont get that warm and fuzzy about any of them or the process of setting them up.

So if you don't mind, what do you guys do?