I just moved into a new home with a large, 3 car garage. I need a workbench that can be dual purpose - a general bench for random house projects, and second, a sturdy bench that I can mount 2 or more reloading presses, with enough room for other reloading odds and ends. Previously, I used a press mounted to a piece of 2x6 mounted in a Jawhorse. What are my options for such a table? Note that I am an extreme beginner when it comes to wood working, having never really built anything involving wood. However, I have access to a number of tools - circular saw and miter saw. I do not have access to a table saw. What would your recommendation be? Buy something pre-made, or build something that someone with my experience and tools can handle? Ideally i'd also like a backboard where I can hang tools like hammers, etc to get them out of the way.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Buy or Build a sturdy workbench/reloading bench?

- Thread starter hkfan45

- Start date

I used these. You can pretty much size it to whatever dimensions you need, and sturdy as heck. You have the tools to deal with the 2×4s, and you can get the plywood cut to fit.

Build it. Hammer and nails or drill and screws makes easy work of it.

How pretty it is depends on how much effort you put in but functionally it’s a stack of lumber.

How pretty it is depends on how much effort you put in but functionally it’s a stack of lumber.

Build it. I am by no means a craftsman but I took some left over wood from my deck build and put together a sturdy bench with 4x4s and 2x6s and it does what I need for loading. I lag bolted it to the wall also and it doesn't move.

I built mine because the right height for you is important.

I bought a set of the Sam's Club benches and tool box. They were a lot cheaper when I bought. I use the bench for my press and loading. I use the long cabinet for storing my loading supplies and the tool box sits under the loading bench and can be pulled out if needed. Adjustable feet made it simple and easy to level the loading bench. I keep it in a "L" shape and can move the table/cabinet in parallel with the loading bench for more room in needed. It's in the third car bay of my garage and rarely needs to be moved.

Workbench:

www.samsclub.com

www.samsclub.com

Rolling workbench/cabinet:

www.samsclub.com

www.samsclub.com

Rolling toolbox/cabinet:

www.samsclub.com

www.samsclub.com

Workbench:

Workbenches, Work Tables & Work Stations - Sam's Club

Rolling workbench/cabinet:

Let us know you're not a robot - Sam's Club

Rolling toolbox/cabinet:

Let us know you're not a robot - Sam's Club

Build using construction lumber, and lag bolts. I have plans I can post, but it won’t be until another week or so.

You can build the bench with just a circular saw. You can also scale up lumber sizes if you want to use 4x4 legs. Simple 2x10 plank top so easy to to replace boards as needed.

Buy the lumber, sticker and let sit in the garage for a month or so.

Will it be a sit down or stand up work bench?

At the end of the day, a table/bench is just a big ass square or rectangle.

If you’re wanting to buy one, I’ll make you a heirloom quality bench for $12,000 lol.

You can build the bench with just a circular saw. You can also scale up lumber sizes if you want to use 4x4 legs. Simple 2x10 plank top so easy to to replace boards as needed.

Buy the lumber, sticker and let sit in the garage for a month or so.

Will it be a sit down or stand up work bench?

At the end of the day, a table/bench is just a big ass square or rectangle.

If you’re wanting to buy one, I’ll make you a heirloom quality bench for $12,000 lol.

Last edited:

I put in 8’ of base cabinets and covered the top with 2 layers of 3/4” plywood glued together, makes a super solid bench and gives you plenty of storage.

I'd say since you are new to woodworking buying would be better. Find a premade table/bench that fits the space and your budget. This will give you time to reload on a solid base and discover what you want in a better reloading bench. It also gives you time to practice your wood working and improve your skill to build your perfect bench.

Thanks for the offer but probably a little rich for my blood. It will be a sit down bench.Build using construction lumber, and lag bolts. I have plans I can post, but it won’t be until another week or so.

You can build the bench with just a circular saw. You can also scale up lumber sizes if you want to use 4x4 legs. Simple 2x10 plank top so easy to to replace boards as needed.

Buy the lumber, sticker and let sit in the garage for a month or so.

Will it be a sit down or stand up work bench?

At the end of the day, a table/bench is just a big ass square or rectangle.

If you’re wanting to buy one, I’ll make you a heirloom quality bench for $12,000 lol.

Lol. Just thought I’d throw that in for humor.Thanks for the offer but probably a little rich for my blood. It will be a sit down bench.

Sit down bench, 28-29”legs with a 1-2” top. You don’t need super thick for the whole top and can just reinforce underneath the press.

Make sure the bench is either very heavy, or we’ll anchored. It’s not so much the down force, but the odd up force of priming and moving the press handle back in position.

I’d use 2x10 or 2x12’s for a top, no deeper than 24”. If you want a solid top you can laminate plywood or buy a butcher block top from lowes made of beech.

In all honesty though, those store benches already posted would be what I’d get. I’d rather just plop it in and set up vs building.

I've got a half-dozen of the HF benches in the shop- fine for general purpose shit and the drawers are a plus- can't buy the lumber for what they cost. They're a bit flimsy side-to-side but where it matters I beefed them up with X-braces on the back side to eliminate that issue.

To build from scratch, my more "sturdy" benches are framed from 2x8 lumber with solid core doors as the tops that I scrounged from our jobsites where they'd been damaged cosmetically, wrong hand, wrong prep, etc.

It would be worth checking with your local Depot/Lowes to see if they ever have damaged ones that they'd give you or sell at a discount.

To build from scratch, my more "sturdy" benches are framed from 2x8 lumber with solid core doors as the tops that I scrounged from our jobsites where they'd been damaged cosmetically, wrong hand, wrong prep, etc.

It would be worth checking with your local Depot/Lowes to see if they ever have damaged ones that they'd give you or sell at a discount.

I was leaning towards buying but it seems difficult to find a short enough bench for sitting that is super sturdy. Any suggestions?Lol. Just thought I’d throw that in for humor.

Sit down bench, 28-29”legs with a 1-2” top. You don’t need super thick for the whole top and can just reinforce underneath the press.

Make sure the bench is either very heavy, or we’ll anchored. It’s not so much the down force, but the odd up force of priming and moving the press handle back in position.

I’d use 2x10 or 2x12’s for a top, no deeper than 24”. If you want a solid top you can laminate plywood or buy a butcher block top from lowes made of beech.

In all honesty though, those store benches already posted would be what I’d get. I’d rather just plop it in and set up vs building.

What is your idea of sturdy?I was leaning towards buying but it seems difficult to find a short enough bench for sitting that is super sturdy. Any suggestions?

4x4 legs and 2x4 aprons and stretchers should be more than sturdy enough. If building a multipurpose bench, with permanently mounted reloading equipment, I’d make it a minimum of 6’ long.

Honestly, I’d build 3’ long bench for reloading, mount pegboard on the wall behind it. Then build a separate bench for all other uses. You’ll appreciate this years down the road. A reloading bench should be for reloading.

Build another bench for gunsmithing, working on weed eaters, etc. They are easy to build with screws and lag bolts and will outlast you. It’s not show furniture so you don’t need pocket screws or any of that. Just drill right through!

Last edited:

Sturdy enough for a Dillon progressive press and my single stage forester.What is your idea of sturdy?

It doesn’t take as much as one would think. It’s convenient that I’m at my friend’s house this weekend. I built this one in 2012, and it’s been a reloading bench, gunsmithing bench, and is now a catch-all. It’s been disassembled and moved 5 times. Still rock solid. The top is at 42 inches high because it’s a stand up bench. 42 inches is at perfect height for him with his arms 90 degrees to his elbow.Sturdy enough for a Dillon progressive press and my single stage forester.

Made out of construction lumber, screws, and with a circular saw. The lag bolts on the end were left Proud to hang stuff on.

Last edited:

My first bench I built many years ago, and I put a shelf under it where I stored loaded ammo. The extra weight under the bench made a big difference in stability. Just a thought.

Unfortunately I just have my garage which I planned to insulate and have a mini split installed to cool it down. I don’t really have any room in the house for a dedicated reloading room.What ever you decide you should have a secluded and secure room for reloading.

I’ve made a bunch of these over the years at places I go to. Easy to build and I use them for hand tool woodworking. Way more than solid enough for reloading. Overkill, actually. I’d remove the long stretcher on the front for a reloading bench.

Simple 4x4 frame construction with lag bolts. This one is 5’ long. It’s a great bench to build because it gets you up and working fast. Dead solid, no racking, and not moving without considerable effort.

If you want the plans, cut list, and supply list just drop me a line. 34 lag bolts total for the hardware. This is my favorite bench to build. I build roubo and Nicholson benches for other people, but always make these for me. When I get to the mothership next month I’ll take pictures of my benches from my main shop. Same design as these, but 10’ long.

Simple 4x4 frame construction with lag bolts. This one is 5’ long. It’s a great bench to build because it gets you up and working fast. Dead solid, no racking, and not moving without considerable effort.

If you want the plans, cut list, and supply list just drop me a line. 34 lag bolts total for the hardware. This is my favorite bench to build. I build roubo and Nicholson benches for other people, but always make these for me. When I get to the mothership next month I’ll take pictures of my benches from my main shop. Same design as these, but 10’ long.

Last edited:

That looks pretty similar to mine but mine is almost chest high and not as refined in the woodworking. Lol Mine also has the back two 4x4 go up about 3’ above the bench top and I have peg board on it to hang tools and accessories.

My $0.02. I will never have a reloading work bench in a non air conditioned space.

Sturdy enough for a Dillon progressive press and my single stage forester.

The bench @Bigfatcock suggested looks great for a garage space all-purpose bench. If you have the tools and the time, I’d do that.

I’ve got the tools and like to build stuff, but at the time I wanted to get my reloading rig up and running, I didn’t really have the time and didn’t really have the workspace to mess with that due to work/life (similar situation though: new house).

I went with easy, and got one of the benches @Jefe's Dope mentioned. If you can bolt the sucker to wall studs with L-brackets, it will do its thing as a simple solid bench.

There is a quite a lot to what you have said.My $0.02. I will never have a reloading work bench in a non air conditioned space.

We have a large shop and no heating or air. In humid Louisiana, rust is endemic. So, I keep my powders and primers in our home. I keep my dies in the gun safe with a dehumidifier running constantly. It is a hassle and I would love to move the entire operation into the bike shop which has the ability to be air conditioned. Problem is, there is no room in the bike shop and our little cottage on the lake is way too small.

Given the choice, I would change. But a better choice is to build a room in the shop and put in an efficient heat/cool unit.

Don’t want to put treated lumber inside your reloading room, (the only 4x4’s available locally) much less pay the current price for 4x4’s. And you have a table saw.

Take a cheap 2x4 stud. Cut them to the same length (generally say 41 inches for a 42 inch table top, your mileage may and probably will vary). Drill them and glue in dowel rods about two inches from bottom top and one in the middle connecting the two glued pieces. When dry, trim each edge with the table saw. When you have all four needed, make sure they are all cut to the same exact length.

Your 4x4’s which actually will be slightly smaller than factory/mill produced 4x4’s, once trimmed will look just as good, be just as strong and be priced less than a 4x4. Remember, your time is free (if you have the time to spare)

Take a cheap 2x4 stud. Cut them to the same length (generally say 41 inches for a 42 inch table top, your mileage may and probably will vary). Drill them and glue in dowel rods about two inches from bottom top and one in the middle connecting the two glued pieces. When dry, trim each edge with the table saw. When you have all four needed, make sure they are all cut to the same exact length.

Your 4x4’s which actually will be slightly smaller than factory/mill produced 4x4’s, once trimmed will look just as good, be just as strong and be priced less than a 4x4. Remember, your time is free (if you have the time to spare)

The second workbench I posted is honestly severe overkill for a reloading bench. Very heavy. It would be better suited for a general workbench with a strong vise.

The Sam’s club benches are more than good enough for reloading.

If you’re going to rip boards to glue up legs, I’d get 2x12’s and rip those. Use a stop block on the miter saw.

The Sam’s club benches are more than good enough for reloading.

If you’re going to rip boards to glue up legs, I’d get 2x12’s and rip those. Use a stop block on the miter saw.

I only trim the edges. I have ripped plenty of boards to make smaller when required, but 2x4’s in my area are the least expensive wood per bd ft. I’m into inexpensive when quality does not suffer. (Plus being 73, I handle 2x12’s only when I have too. )The second workbench I posted is honestly severe overkill for a reloading bench. Very heavy. It would be better suited for a general workbench with a strong vise.

The Sam’s club benches are more than good enough for reloading.

If you’re going to rip boards to glue up legs, I’d get 2x12’s and rip those. Use a stop block on the miter saw.

But you have a great point on the store bought benches. We have a Craftsman bench for reloading and it is as solid for reloading as any I have made.

Not bad for the price and time invested to get it up an running. I've had mine for years now and zero complaints. I'm not in the garage on projects all the time but for my use, it's been more than adequate and I wouldn't hesitate to buy again. It really helped organize my third car bay as well. I also use one of those cheap, but not shitty, $30 Walmart folding tables. When I found those for $30 a couple years ago, I bought at least four, two for my RV, and two for general use around home. They get used all the time. Used one for a desk in my office at work for five+ years. Was supposed to be temporary as I bought my partner out an he insisted on taking his POS folding table we used as a desk forever. Again was supposed to be temporary.The bench @Bigfatcock suggested looks great for a garage space all-purpose bench. If you have the tools and the time, I’d do that.

I’ve got the tools and like to build stuff, but at the time I wanted to get my reloading rig up and running, I didn’t really have the time and didn’t really have the workspace to mess with that due to work/life (similar situation though: new house).

I went with easy, and got one of the benches @Jefe's Dope mentioned. If you can bolt the sucker to wall studs with L-brackets, it will do its thing as a simple solid bench.

View attachment 7847112

I used the 2x4 basics kit off of Amazon. Luckily I had most of the lumber left over from another project. Final dimensions are 6’long 33” deep and 3’ tall. Forgive the mess as I just assembled it yesterday and just threw a bunch of shit on top to get it out of the way. I may or may not stain. I will probably at least poly the top. The cost of the kit may be a wash vs lumber but I do know that it was super easy to put together and extremely solid.

I would skip staining. Pine takes alot of work to stain without blotching and grain reversal, and looks like shit if you didn’t do the prep work. Just use it, lol. If you have to have some color, sand it, seal it, and paint it.I used the 2x4 basics kit off of Amazon. Luckily I had most of the lumber left over from another project. Final dimensions are 6’long 33” deep and 3’ tall. Forgive the mess as I just assembled it yesterday and just threw a bunch of shit on top to get it out of the way. I may or may not stain. I will probably at least poly the top. The cost of the kit may be a wash vs lumber but I do know that it was super easy to put together and extremely solid.

View attachment 7847350

I would love the plans if you have them to spare please, sent you a pmI’ve made a bunch of these over the years at places I go to. Easy to build and I use them for hand tool woodworking. Way more than solid enough for reloading. Overkill, actually. I’d remove the long stretcher on the front for a reloading bench.

Simple 4x4 frame construction with lag bolts. This one is 5’ long. It’s a great bench to build because it gets you up and working fast. Dead solid, no racking, and not moving without considerable effort.

If you want the plans, cut list, and supply list just drop me a line. 34 lag bolts total for the hardware. This is my favorite bench to build. I build roubo and Nicholson benches for other people, but always make these for me. When I get to the mothership next month I’ll take pictures of my benches from my main shop. Same design as these, but 10’ long.

View attachment 7842362View attachment 7842363

I’ll dig them out and get them posted.I would love the plans if you have them to spare please, sent you a pm

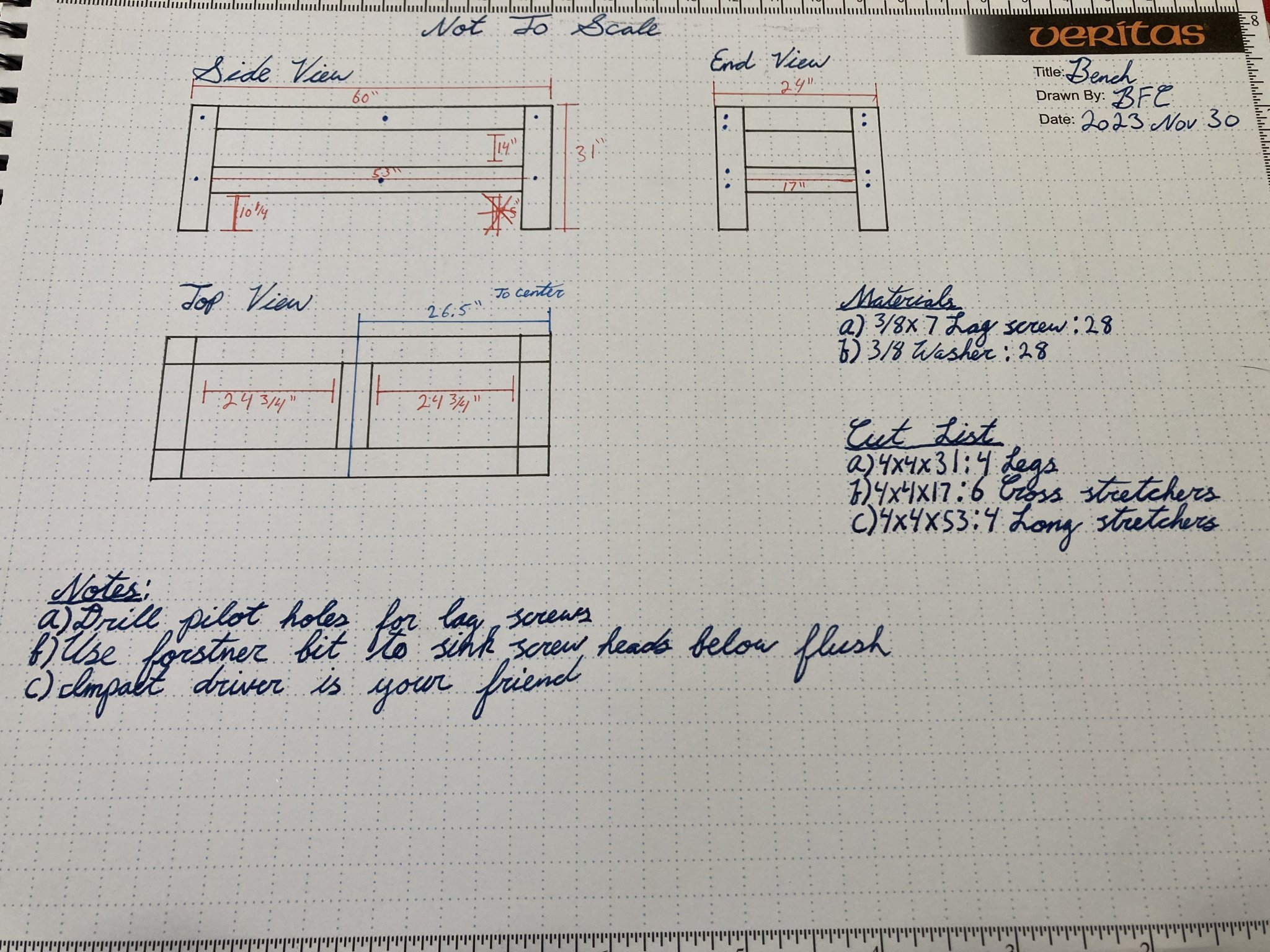

I couldn’t find the plans so drew up some new ones right quick. Super easy to build with no complex joinery, and can be done entirely with a circular saw, a drill, and wrenches (I highly recommend an impact driver though!).

All measurements already take into account that a 4x4 is actually 3.5x3.5.

2 lag screws for anchoring into the long stretchers.

One lag screw for anchoring into the cross stretchers. You’re essentially sticking the single cross stretcher lag screw between the 2 long stretcher screws.

There is no top on these drawings since you can put whatever top you want on there. My top dimensions are 60x24, but this frame is more than stable enough to have 4-6 inches of overhang around the sides.

You can also easily scale this up if you want a longer or wider frame.

This bench is going on 4 years old and you can see where the wood has dried and shrunk. I could eliminate all those gaps by tightening up the lag screws, but it’s still solid so I leave it alone.

All measurements already take into account that a 4x4 is actually 3.5x3.5.

2 lag screws for anchoring into the long stretchers.

One lag screw for anchoring into the cross stretchers. You’re essentially sticking the single cross stretcher lag screw between the 2 long stretcher screws.

There is no top on these drawings since you can put whatever top you want on there. My top dimensions are 60x24, but this frame is more than stable enough to have 4-6 inches of overhang around the sides.

You can also easily scale this up if you want a longer or wider frame.

This bench is going on 4 years old and you can see where the wood has dried and shrunk. I could eliminate all those gaps by tightening up the lag screws, but it’s still solid so I leave it alone.

Last edited:

I've had a whole reloading room with benches attached to the framing of the building. Now that I'm mobile, I've been using a tool cabinet that I strap to the metal on my shop to keep it from wandering. It's great. Has about 8 drawers, good top, and I can move it where I need to.

I’m no expert cabinet maker but I have some tools and can do some things. I built this with a 4x8 sheet of 3/4” plywood stacked for 1.5” top, 4x4 posts and the rest from 2x4s. You could park a car on this. I also bolted this to the studs in the wall. Works for me.

Similar threads

Reloading Equipment

Reloading equipment for sale

- Replies

- 7

- Views

- 978

- Replies

- 16

- Views

- 1K