Wow. guys. i didn't expect such interest.

Technology wise the steps are the follwoing:

1. We put carbon prepreg into the mold, overlapping the joint line in the mold. We do it in 15 degree difference between layers. overal width of the carbon vary from 0,8mm to 3mm.

Under action we put prepreg inline with the action making additional layers under recoil lug up to 5 mm. We put steel liners between layers of carbon prepreg in areas of pillars and studs.

One stock require aroun 10 sq.meters of prepreg.

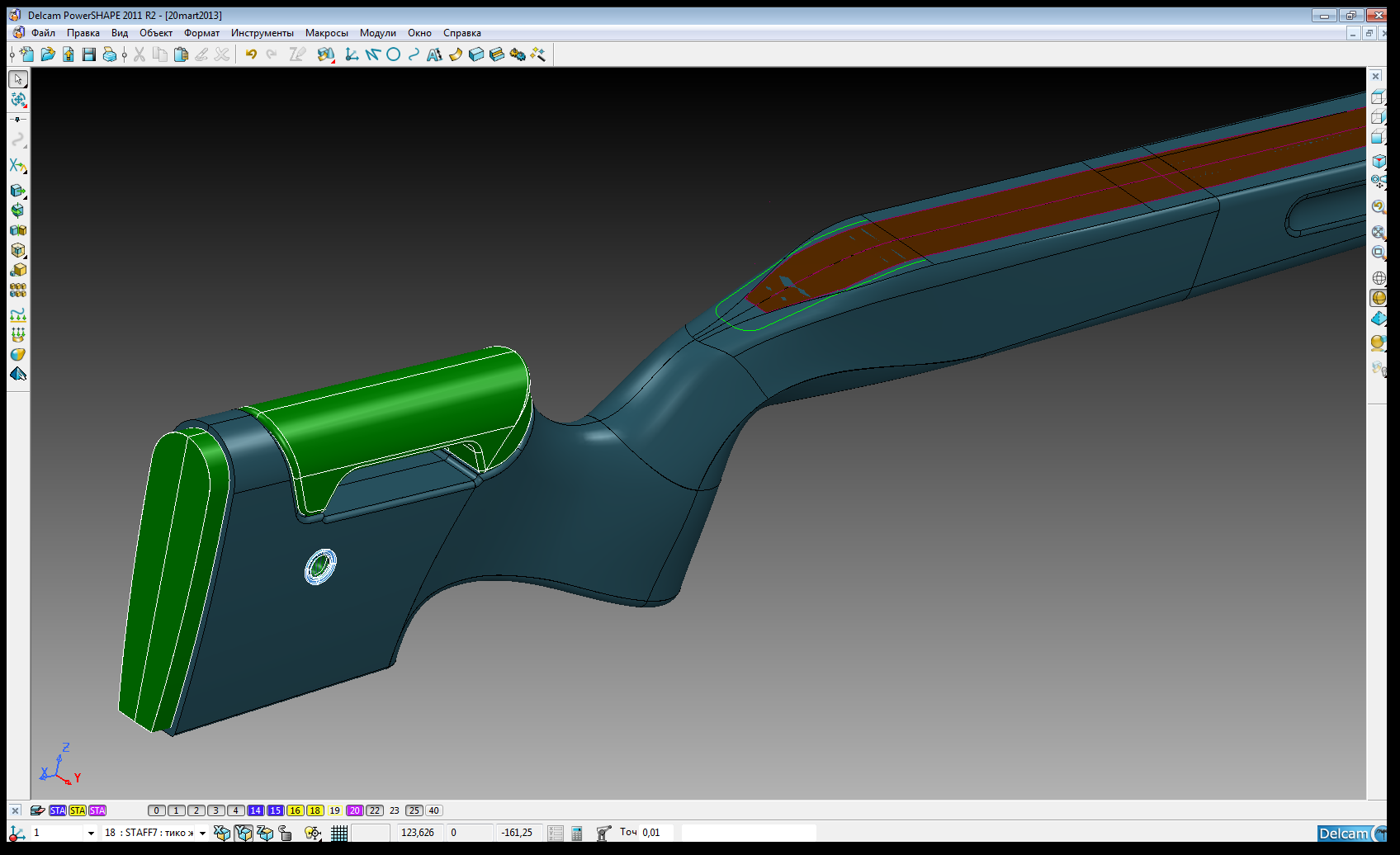

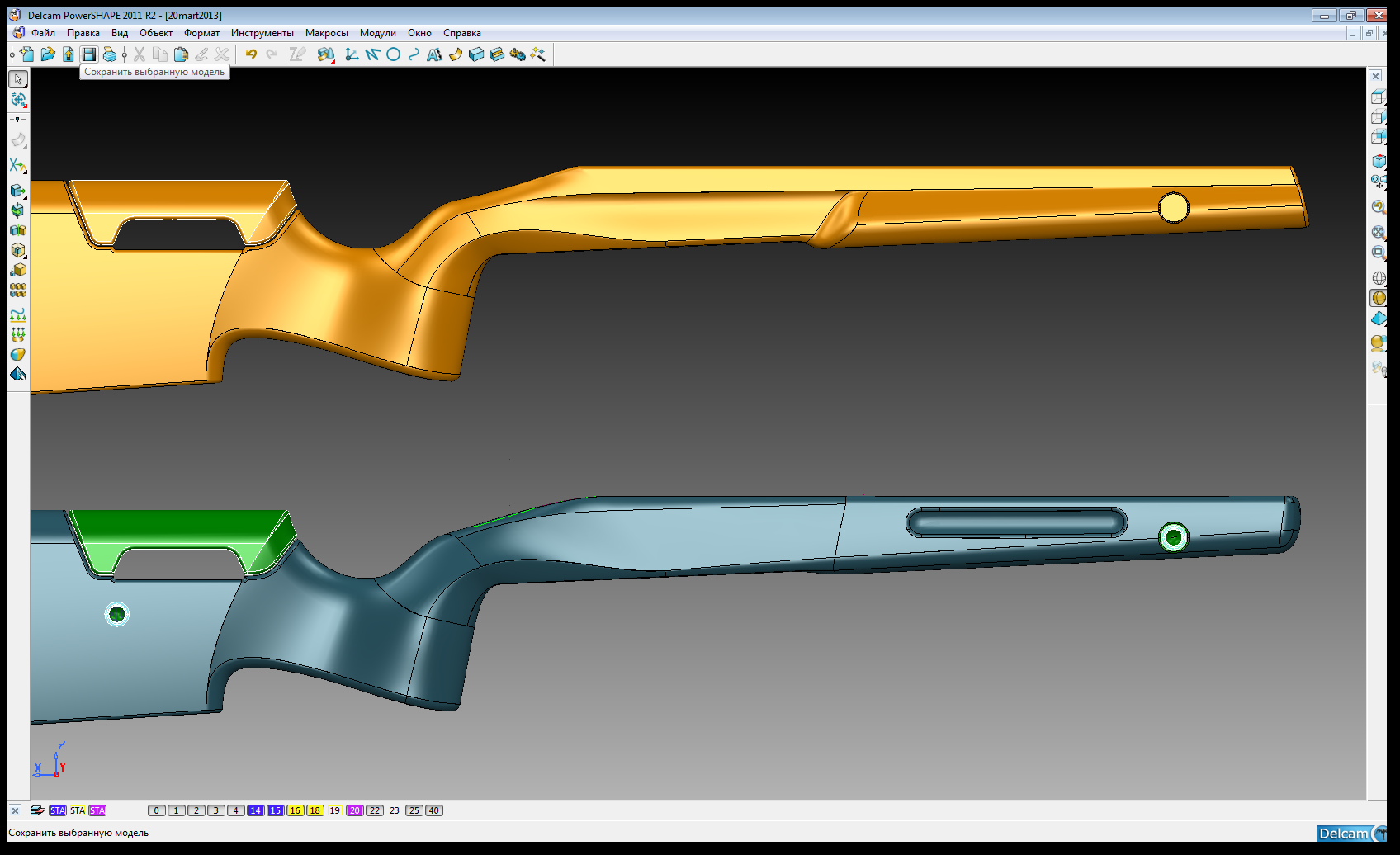

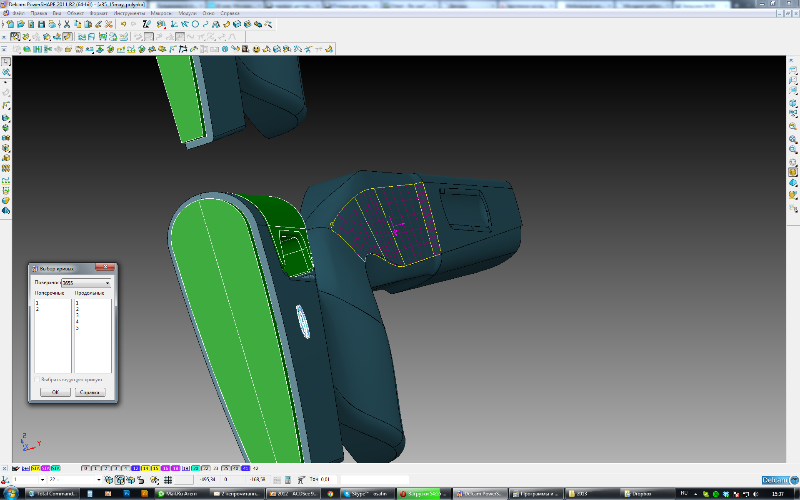

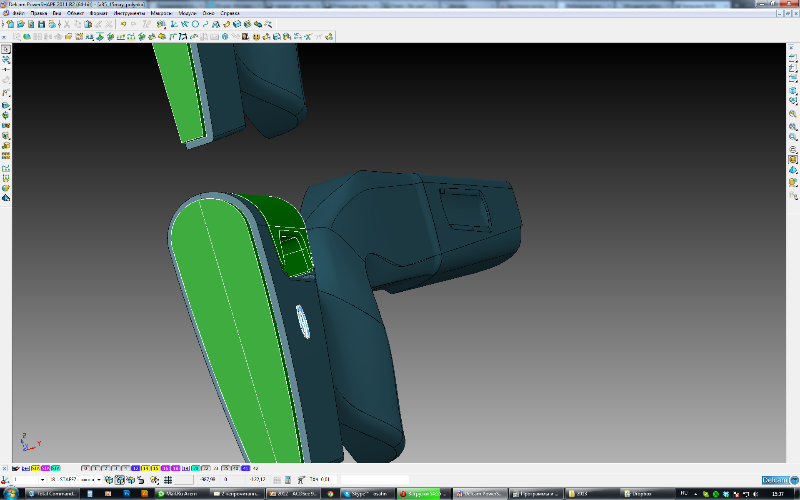

here is the photo of the mold:

it should have mirror surface to allow remove the cooked carbon:

2. We put the pressure camera inside the stock (so carbon prepreg layes between pressure camera and mold) and cook the stock with the pressure putted into camera for 8 hours.

3. We let the stock to cool down to the room temperature, remove the pressure camera and cook the stock for additional 8 hours to remove stress from the carbon

4. After that we remove the stock blank from the mold and remove spew from the joint lines.

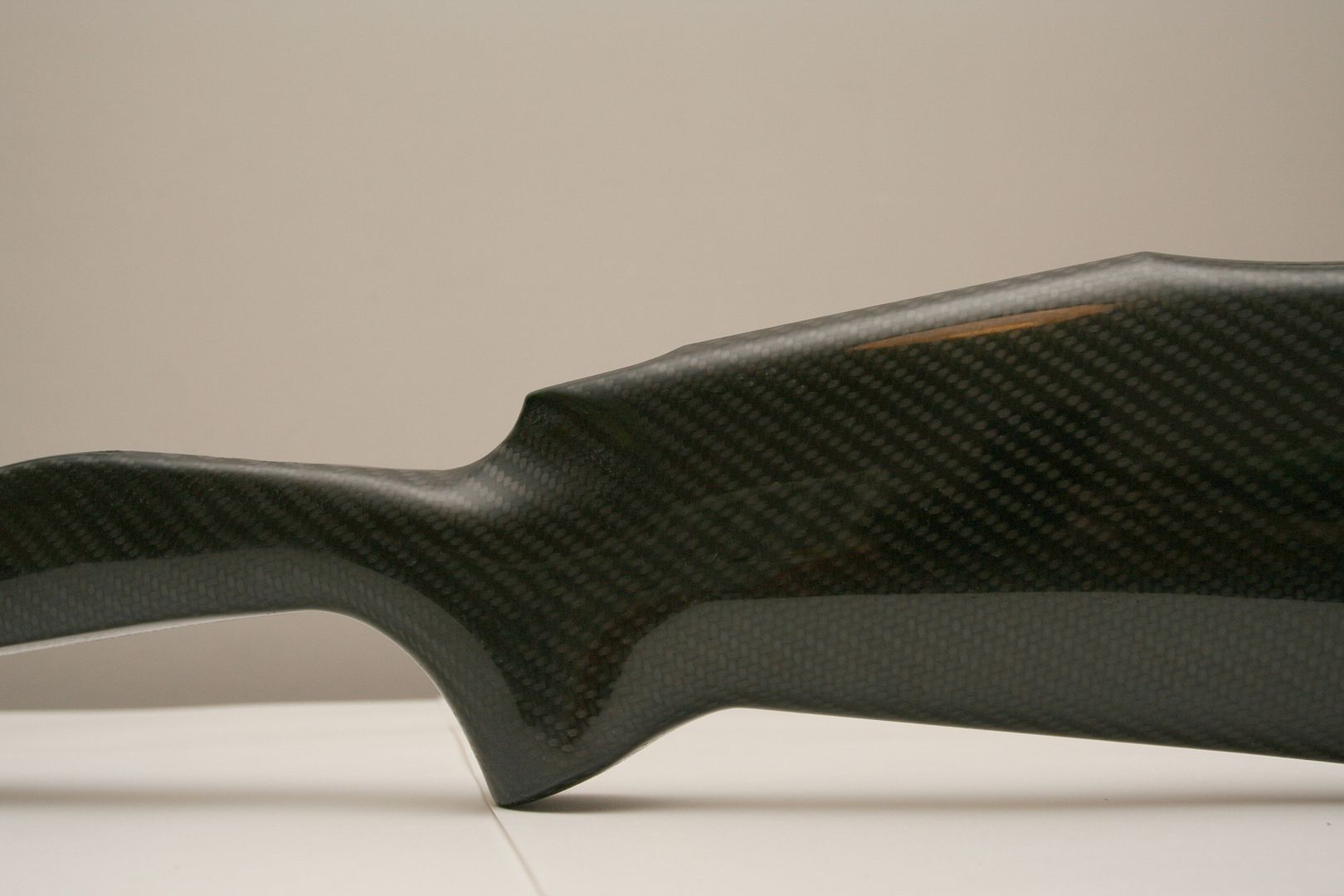

After that we have the blank with formed barrel channel and action channel:

here how it looks like for tikka t3:

5. After that we fill the action area with special fill which can be machined, and fill foreend and stock with light foam (175g on 1 cubic decimeter)

6. We machine inlet, install pillars, sling studs, run finish on the stock surface

7. If the customer wants - we machine 0,2 mm from the carbon at action area and form action inlet with devcon bedding using polished action blank (the stocks in the first post done with this step)

8. We cover the stock with special anti-adhesion cover (it's done at 90C) to make the stock not so slippery. If customer want to paint the stock he should remove this layer of cover with acetone prior painting.

9 stock is ready to go.

PS

BTW - the stock for Air PCP rifle from this report -

Target Shooter Magazine April Issue Features IWA Show Report « Daily Bulletin - also was made by us: