Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chamber question

- Thread starter 232593

- Start date

That’s not the best photo but it looks like marks from the brass going in and out and not the chamber cut.

Try to get another photo if you can.

A bad chamber cut looks like this and marks the brass accordingly when fired. That shit came from a manufacturer of a prefit.

Try to get another photo if you can.

A bad chamber cut looks like this and marks the brass accordingly when fired. That shit came from a manufacturer of a prefit.

Attachments

That’s not the best photo but it looks like marks from the brass going in and out and not the chamber cut.

Try to get another photo if you can.

A bad chamber cut looks like this and marks the brass accordingly when fired. That shit came from a manufacturer of a prefit.

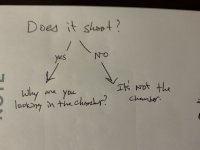

Proof lol?

I didn’t think brass was hard enough to scratch steel.That’s not the best photo but it looks like marks from the brass going in and out and not the chamber cut.

Try to get another photo if you can.

A bad chamber cut looks like this and marks the brass accordingly when fired. That shit came from a manufacturer of a prefit.

My pic is admittedly a bit shitty, the gunsmith’s bore scope was having some issues when we tried to get a screen capture. But it looked similar to the pic you posted.

oh so sorry signs of ed at such an early age it's terrible . but fear not you can get it fixed but it will be painful .

It’s supposedly brand new.oh so sorry signs of ed at such an early age it's terrible . but fear not you can get it fixed but it will be painful .

No if you hold the barrel up to the light you can see the marks without the aid of a bore scope.Looks great, maybe a little fuzzy ?

Does it feed well?

If you get a chamber too smooth you lose grip on the brass and can give you false pressure signs. A cross hatch finish like on piston cylinder walls is about ideal.

If it feeds without sticking it’s fine. If brass sticks while trying to eject, you can deburr with a dowel rod and Emory cloth.

If you get a chamber too smooth you lose grip on the brass and can give you false pressure signs. A cross hatch finish like on piston cylinder walls is about ideal.

If it feeds without sticking it’s fine. If brass sticks while trying to eject, you can deburr with a dowel rod and Emory cloth.

Last edited:

So far it has fed ok. The gunsmith that I took it to said it was way too rough. He showed me a pic of some cheap AK chambers he had and mine was way rougher.Does it feed well?

If you get a chamber too smooth you lose grip on the brass and can get false pressure signs. A cross hatch finish like on piston cylinder walls is about ideal.

If it feeds without sticking it’s fine. If brass sticks while trying to eject, you can deburr with a dowel rod and Emory cloth.

I understand that this is in "Bolt Action Rifles", and I'm not implying that your barrel's chamber was done intentionally, but the LaRue OBR barrel chambers have longitudinal grooves intended to help with extraction. They call it "Xtraxn", and more than one person has lapped the chamber to remove the grooves thinking it was a flaw or defect.

Does Desert Tech chamber their own or do they outsource it?Desert Tech

I have an ES tactical desert tech barrel that is rough at the neck/shoulder junction. Intentional or not, I don’t know. Smooth everywhere else. The brass looks good after firing. What does your fired brass look like?

No idea.Does Desert Tech chamber their own or do they outsource it?

The brass does have markings similar but not as severe as @Cberndt ’sI added to my post when you quoted me. Check it out.

You know that cylinder crosshatching is used to hold oil for lubrication and guiding piston ring rotation right?Does it feed well?

If you get a chamber too smooth you lose grip on the brass and can give you false pressure signs. A cross hatch finish like on piston cylinder walls is about ideal.

If it feeds without sticking it’s fine. If brass sticks while trying to eject, you can deburr with a dowel rod and Emory cloth.

I've yet to see evidence of "too smooth" chamber finish. Under firing pressure the case is going to compress the ejector (and spring) before brass expands.......the whole path of least resistance thing. As far as "wall grip"......take two precision ground surfaces and squeeze them together......good luck getting them apart. Just my observations over the years.

In my experience, I like to use 400grit polishing to knock down reamer machining marks and break any sharp edges that can shave jacket or brass during operation.

Not sure what happened to the above chamber. Either live with it or contact the maker. Completely your call, I've seen both extremes......shooters who can't live with any evidence of use.......and shooters that are shooting homebrew mixed part rifles because it shoots decent enough.

Ern

Last edited:

Does it have potential to become a problem later on?looks like a bit of reamer chatter/vibration when the chamber was cut. Reamers will chatter/vibrate for a number of reasons, creating a washboard finish in the wall of the chamber.

The manufacturer has been contacted and I’m awaiting a response.You know that cylinder crosshatching is used to hold oil for lubrication and guiding piston ring rotation right?

I've yet to see evidence of "too smooth" chamber finish. Under firing pressure the case is going to compress the ejector (and spring) before brass expands.......the whole path of least resistance thing. As far as "wall grip"......take two precision ground surfaces and squeeze them together......good luck getting them apart. Just my observations over the years.

In my experience, I like to use 400grit polishing to knock down reamer machining marks and break any sharp edges that can shave jacket or brass during operation.

Not sure what happened to the above chamber. Either live with it or contact the maker. Completely your call, I've seen both extremes......shooters who can't live with any evidence of use.......and shooters that are shooting homebrew mixed part rifles because it shoots decent enough.

Ern

I can deal with evidence of use, however this was supposed to be a new barrel extension. But I don’t want a defect that will cause issues later on.

I think you are on the right track. If your concerns/expectations are realistic (and I believe they are) then you need to get what you paid for.

Keep us posted on the status, customer service in this industry goes a LONG WAY.

Ern

Keep us posted on the status, customer service in this industry goes a LONG WAY.

Ern

Will do. Believe that.I think you are on the right track. If your concerns/expectations are realistic (and I believe they are) then you need to get what you paid for.

Keep us posted on the status, customer service in this industry goes a LONG WAY.

Ern

Similar threads

- Replies

- 30

- Views

- 1K

- Replies

- 0

- Views

- 119