For those of you who don't know what to look for....I have just a little over 6,000 rounds through one of my Colt 6933s. This particular carbine has been my training rig, and close to 2,000 of that has been run suppressed. This carbine since day one has been run with an H3 buffer. The last time I cleaned this carbine was at the first of June, just prior to Pat Rogers' Alliance Ohio shoothouse class. Last week I broke it down for cleaning and inspection, then noticed a small crack at the cam pin hole on my Colt bolt. I snapped some pictures of the crack, then used a dye penetrate kit from work to look the bolt over real good and took some more pictures. You can see the crack, as well as some pitting on the bolt lugs and bolt tail from the hot gases blown back into the action during firing. The pitting shows up as the white powdery looking areas, once the bolt is wiped down after the dye penetrate process.

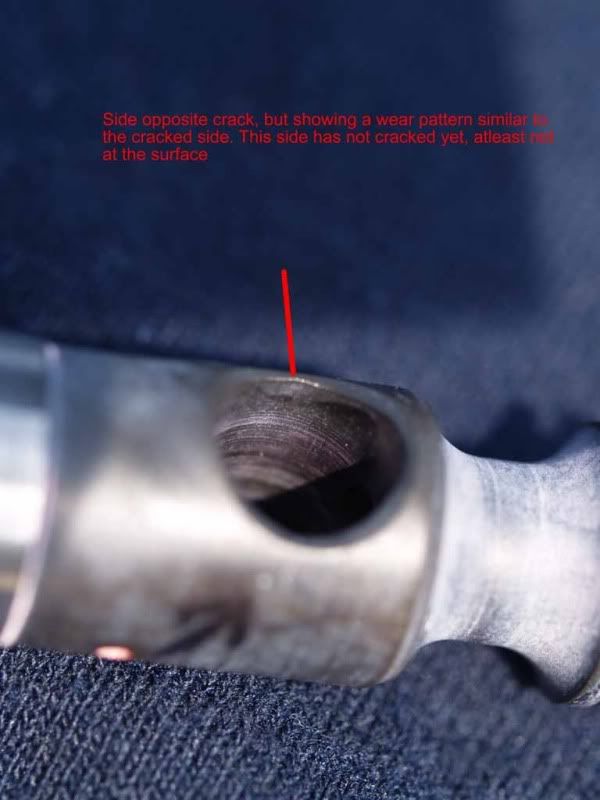

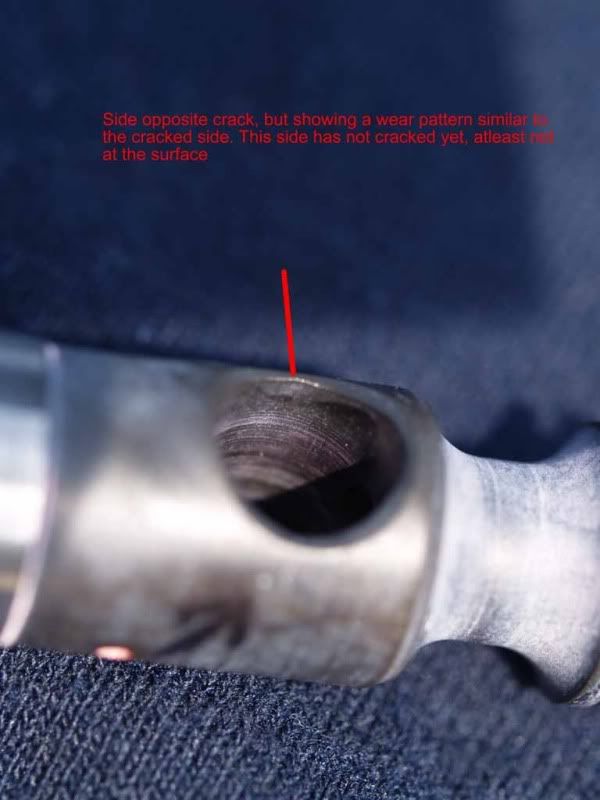

As far as the crack at the cam pin goes, most that I have seen, seem to start at the top side of the bolt (where the cam pin slides in), and the side opposite the extractor. You can see the discoloration of this area in the photos, in a V shaped pattern. Most cracked bolts I've seen also seem to crack from the inside of the cam pin hole outwards. So pay attention to the inside of the hole more so than the outside. If you have worked around broken metal parts, you will know, usually the rough torn looking edge is the last area to fail. The clean break area is the first. Most pictures of broken bolts at the cam pin hole online show this same pattern. Pay close attention to the inside of the cam pin hole opposite the extractor. This is the area where the force of the cam pin is pushed against the bolt during firing. Over time the cam pin and the bolt at the inside of the cam pin hole will start to wear. As they wear, tolerances open up, and when that happens the pin starts to "hammer" if you will against the cam pin hole instead of pushing it. This will eventually lead to failure at the cam pin hole. I believe it is a good idea to replace the cam pin every 1 or 2 thousand rounds to atleast mitigate the opening up of these tolerances. I did not do this on my training gun just to see how long parts would last, but do on my other guns.

If you have any doubt, there are several companies that sell dye penetrate. Magnaflux is one, Sherwin Williams industrial division carrys one as well. You local welding shop is the easiest place I've found to find it. It is a very simple process and will tell you if you have any surface cracks. If you really want to get technical, any local crane company "should" have magnetic particle inspection equipment. This will allow you to check for sub surface cracks. For an agency that has a lot of rifles, it might be feasible to schedule a day to have a guy come out and check parts. It is a pretty quick and simple process.

Finding this before it fails is key. This would be a good little speed bump on the range, and a bad day in a gun fight...

As far as the crack at the cam pin goes, most that I have seen, seem to start at the top side of the bolt (where the cam pin slides in), and the side opposite the extractor. You can see the discoloration of this area in the photos, in a V shaped pattern. Most cracked bolts I've seen also seem to crack from the inside of the cam pin hole outwards. So pay attention to the inside of the hole more so than the outside. If you have worked around broken metal parts, you will know, usually the rough torn looking edge is the last area to fail. The clean break area is the first. Most pictures of broken bolts at the cam pin hole online show this same pattern. Pay close attention to the inside of the cam pin hole opposite the extractor. This is the area where the force of the cam pin is pushed against the bolt during firing. Over time the cam pin and the bolt at the inside of the cam pin hole will start to wear. As they wear, tolerances open up, and when that happens the pin starts to "hammer" if you will against the cam pin hole instead of pushing it. This will eventually lead to failure at the cam pin hole. I believe it is a good idea to replace the cam pin every 1 or 2 thousand rounds to atleast mitigate the opening up of these tolerances. I did not do this on my training gun just to see how long parts would last, but do on my other guns.

If you have any doubt, there are several companies that sell dye penetrate. Magnaflux is one, Sherwin Williams industrial division carrys one as well. You local welding shop is the easiest place I've found to find it. It is a very simple process and will tell you if you have any surface cracks. If you really want to get technical, any local crane company "should" have magnetic particle inspection equipment. This will allow you to check for sub surface cracks. For an agency that has a lot of rifles, it might be feasible to schedule a day to have a guy come out and check parts. It is a pretty quick and simple process.

Finding this before it fails is key. This would be a good little speed bump on the range, and a bad day in a gun fight...