I wanted to take a minute to explain who we are, our focus, and our goals. I am not a gunsmith or a machinist. I am a shooter (and former hot rodder), and everything I do and think revolves around being behind the rifle. When I started shooting PRS rimfire in 2017, I had no idea what I was doing other than knowing I loved to shoot. Being competitive, I thought it could be fun. My first rifle was a CZ455, but I was somewhat disappointed with its performance. So, I ordered a custom CZ455, and again, I was let down by its accuracy. (Side note: I learned how to reload for precision from David Tubb over text, and I got spoiled on what true precision and accuracy meant.)

When Vudoo came out, my first thought was that they were crazy—no one would spend that kind of money on a rimfire. But shortly after, a guy showed up with a Vudoo and promptly outshot us all. On the way home, I reached out to Vudoo to order a barreled action. After some discussion, I asked if they’d make me a deal on two. Cole countered with, “Buy three, and I’ll set you up as a dealer.” “Deal!” I said, and that’s how this all started.

After supplying most of the shooters at TX Precision Matches in Navasota, we quickly encountered the feeding issues that Vudoo became known for. Looking back, we now know it wasn’t the rifle but how we were using them. We added weight and made magazine blockers long before anything was commercially available. One day after a match, as we discussed our problems, I thought, “What if we had a longer, heavier barrel?” I sent a text to Paul from Mullerworks, and he sent down a 1.250, 16-twist blank. The balance problems were solved, and we didn’t lose the accuracy we were getting from the shorter barrels.

Fast forward, and I thought I could make a business out of this. The question was never whether we could chamber and build an accurate rifle, but whether we could do it consistently, over and over, in a semi-production format. That sent me shopping for CNC machines. After many calls to shops across the country, I ended up with a Doosan 2100 LSYB turning center. (Remember, I’m not a machinist, so I was completely lost, but I knew I didn’t want to handle the barrel twice—once to tenon/chamber and again to cut the slots on a mill.) A steep learning curve followed. I made a custom jig to hold the barrel in the hydraulic jaws, and off to the races we went.

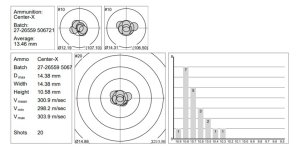

Below are a few samples of the results we’ve achieved over the last couple of years, sending in a few rifles at a time to see where we stood. I’ve also included some results from customers who sent theirs in. My point is this: I want you all to understand that this is a lifestyle choice I made to build and provide the best product I can, one I feel good about selling. We test each rifle for accuracy at 50 and 200 yards. If I’m not satisfied, it doesn’t ship until I’m confident it will meet the customer’s expectations.

When Vudoo came out, my first thought was that they were crazy—no one would spend that kind of money on a rimfire. But shortly after, a guy showed up with a Vudoo and promptly outshot us all. On the way home, I reached out to Vudoo to order a barreled action. After some discussion, I asked if they’d make me a deal on two. Cole countered with, “Buy three, and I’ll set you up as a dealer.” “Deal!” I said, and that’s how this all started.

After supplying most of the shooters at TX Precision Matches in Navasota, we quickly encountered the feeding issues that Vudoo became known for. Looking back, we now know it wasn’t the rifle but how we were using them. We added weight and made magazine blockers long before anything was commercially available. One day after a match, as we discussed our problems, I thought, “What if we had a longer, heavier barrel?” I sent a text to Paul from Mullerworks, and he sent down a 1.250, 16-twist blank. The balance problems were solved, and we didn’t lose the accuracy we were getting from the shorter barrels.

Fast forward, and I thought I could make a business out of this. The question was never whether we could chamber and build an accurate rifle, but whether we could do it consistently, over and over, in a semi-production format. That sent me shopping for CNC machines. After many calls to shops across the country, I ended up with a Doosan 2100 LSYB turning center. (Remember, I’m not a machinist, so I was completely lost, but I knew I didn’t want to handle the barrel twice—once to tenon/chamber and again to cut the slots on a mill.) A steep learning curve followed. I made a custom jig to hold the barrel in the hydraulic jaws, and off to the races we went.

Below are a few samples of the results we’ve achieved over the last couple of years, sending in a few rifles at a time to see where we stood. I’ve also included some results from customers who sent theirs in. My point is this: I want you all to understand that this is a lifestyle choice I made to build and provide the best product I can, one I feel good about selling. We test each rifle for accuracy at 50 and 200 yards. If I’m not satisfied, it doesn’t ship until I’m confident it will meet the customer’s expectations.

Attachments

-

thumbnail_IMG_4129.jpg75 KB · Views: 223

thumbnail_IMG_4129.jpg75 KB · Views: 223 -

20250215_145127.jpg297.2 KB · Views: 270

20250215_145127.jpg297.2 KB · Views: 270 -

20250215_145139.jpg313 KB · Views: 240

20250215_145139.jpg313 KB · Views: 240 -

20250215_145151.jpg301.5 KB · Views: 232

20250215_145151.jpg301.5 KB · Views: 232 -

20250215_153503.jpg319.9 KB · Views: 215

20250215_153503.jpg319.9 KB · Views: 215 -

20250215_153514.jpg320.2 KB · Views: 201

20250215_153514.jpg320.2 KB · Views: 201 -

20250215_153523.jpg349.7 KB · Views: 201

20250215_153523.jpg349.7 KB · Views: 201 -

Screenshot_20250215_150340_Gallery.jpg492.7 KB · Views: 183

Screenshot_20250215_150340_Gallery.jpg492.7 KB · Views: 183 -

Screenshot_20250215_151715_Gallery.jpg698.2 KB · Views: 182

Screenshot_20250215_151715_Gallery.jpg698.2 KB · Views: 182 -

Screenshot_20250215_151801_Gallery.jpg971.6 KB · Views: 161

Screenshot_20250215_151801_Gallery.jpg971.6 KB · Views: 161 -

20250215_145115.jpg270.8 KB · Views: 147

20250215_145115.jpg270.8 KB · Views: 147 -

20240712_202316.jpg294.9 KB · Views: 143

20240712_202316.jpg294.9 KB · Views: 143 -

20240712_202304.jpg303.9 KB · Views: 196

20240712_202304.jpg303.9 KB · Views: 196 -

20240306_173741.jpg319.6 KB · Views: 192

20240306_173741.jpg319.6 KB · Views: 192 -

20240306_173815.jpg306 KB · Views: 128

20240306_173815.jpg306 KB · Views: 128 -

20240306_173835.jpg299.9 KB · Views: 134

20240306_173835.jpg299.9 KB · Views: 134 -

20240313_184428.jpg324 KB · Views: 138

20240313_184428.jpg324 KB · Views: 138 -

20240712_190907.jpg306.6 KB · Views: 131

20240712_190907.jpg306.6 KB · Views: 131 -

20240712_190926.jpg314.7 KB · Views: 126

20240712_190926.jpg314.7 KB · Views: 126 -

20240712_190938.jpg299.2 KB · Views: 126

20240712_190938.jpg299.2 KB · Views: 126 -

20240712_190959.jpg310.8 KB · Views: 131

20240712_190959.jpg310.8 KB · Views: 131 -

20240712_191015.jpg322.9 KB · Views: 148

20240712_191015.jpg322.9 KB · Views: 148 -

20240712_202249.jpg288.1 KB · Views: 233

20240712_202249.jpg288.1 KB · Views: 233

Last edited: