Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Brass Marker

- Thread starter kabarNC

- Start date

So what modeling/cad software did you use for this? Share the stl?

Any chance you are going to market the files or put this out for sale?

Any chance you are going to market the files or put this out for sale?

Last edited:

So what modeling/cad software did you use for this? Share the stl?

Any chance you are going to market the files or put this out for sale?

I'm more of an Autodesk guy lol. This design really had my Haas 5 axis working overtime.

Working on patents of hole design, placement, and product material now, and am planning on selling the product for a small fee of $189.99 ea. While supplies last..

Serious question - I'm kind of new to reloading. Why mark your brass in this way? Just uniquely identifying it for the range or do the two lines provide some sort of information?

Serious question - I'm kind of new to reloading. Why mark your brass in this way? Just uniquely identifying it for the range or do the two lines provide some sort of information?

Alot of us are into precision rifle competitions, where you and about 11 other guys are each shooting a 10 rd string, using the same props to shoot off of. This creates a pile of brass right there, and it's nice to be able to have an identifier on yours, and pick it out of the pile, knowing you got your own brass back.

Got it. Thanks for the reply. I thought at first you were checking for case wear or something...still learning.

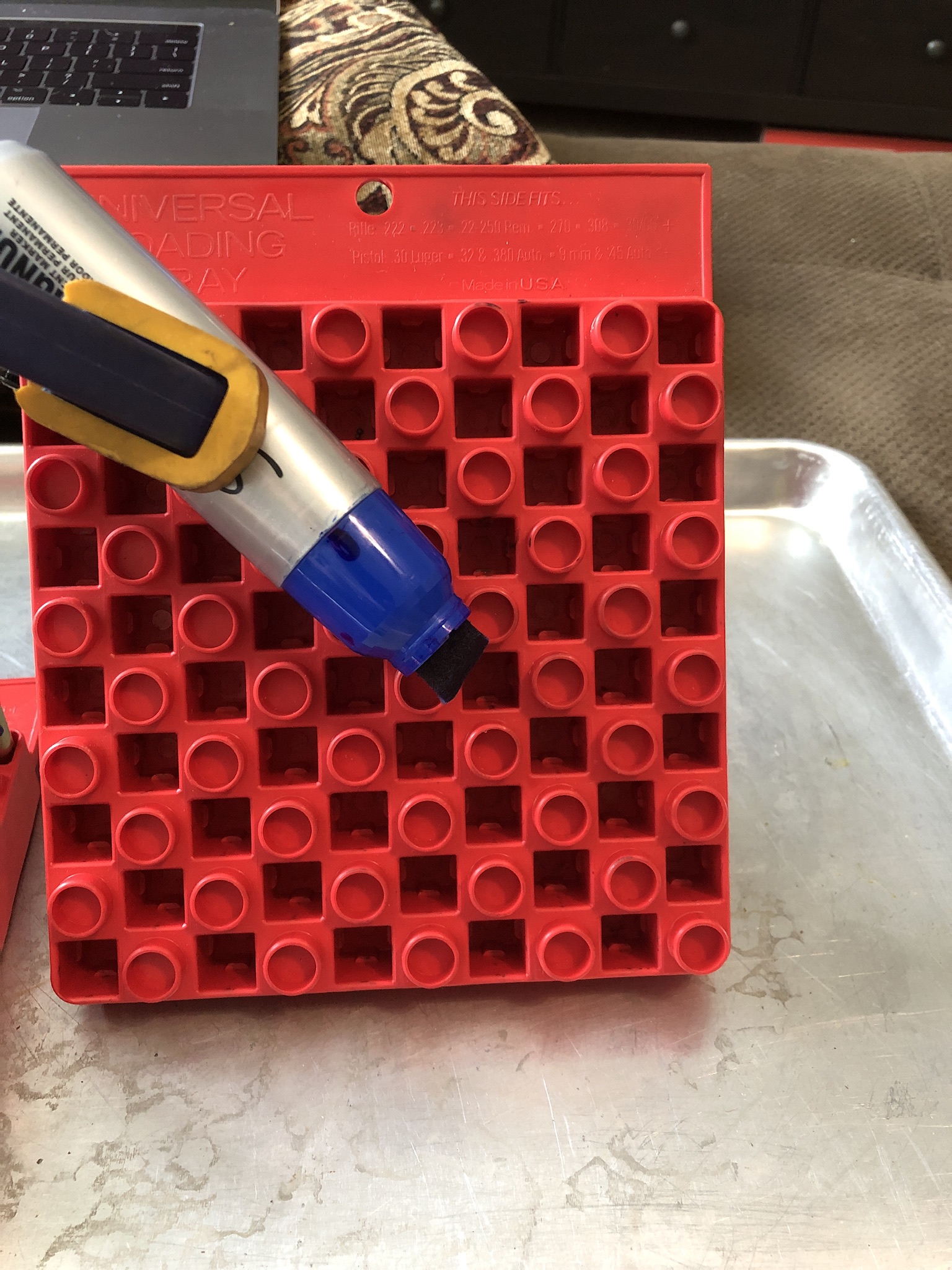

Ill blow your minds even more. Me and buddy do this now after trying all the products out there. Just as fast if not faster, and free (cuz we all have loading blocks already). No need to build something.

And alot of matchs don't give you a lot of time to find your brass in order to keep the match moving alongAlot of us are into precision rifle competitions, where you and about 11 other guys are each shooting a 10 rd string, using the same props to shoot off of. This creates a pile of brass right there, and it's nice to be able to have an identifier on yours, and pick it out of the pile, knowing you got your own brass back.

I cheated and purchased it from cjsprecisionoptics.com was not DIY but looked similar to op.is this 3d printed, for sale?

is this 3d printed, for sale?

There’s a guy in the Px that sells a 3D printed version

Have you guys had trouble cleaning the marker off in a tumbler? I find my tumbler wont take it all off and causes a light bump around the marker when i run my finger through it after tumbling. I have to sit there manually and scrub it off every time.

Swap to wet tumblingHave you guys had trouble cleaning the marker off in a tumbler? I find my tumbler wont take it all off and causes a light bump around the marker when i run my finger through it after tumbling. I have to sit there manually and scrub it off every time.

...and here I've been free-handing it this whole time like a peasant.

Swap to wet tumbling

Are you talking about wet media tumbling? I guess I started out with dry 15 years ago before all these other stuff really kicked off and just havnt purhase any new cleaning gear. I will take a look into it again

I don't use stainless pins or anything. Just harbor freight rock tumbler dawn dish soap and occasionally lemishineAre you talking about wet media tumbling? I guess I started out with dry 15 years ago before all these other stuff really kicked off and just havnt purhase any new cleaning gear. I will take a look into it again

awesome thanks ill look into that.I don't use stainless pins or anything. Just harbor freight rock tumbler dawn dish soap and occasionally lemishine

This thread was a couple months old.. But I always mark brass on my handloads with a date so I can match it to my log book records if needed. Sometimes I also mark things like brass weight, runout and headspace clearance - all depending on where I am with workup. Good luck to you!

Nothing fancy here. Sharpie how many grains of what powder and boolit wt. Same as my 20ga handloads... lead or hevishot, payload, shot size.

Great idea.

I mark the cartridge base, to keep the ink o/o the chamber.

Using a Magnum Red Marker, I swipe the entire head stamp area; then cover one half with a Black Magnum. This leaves a split red/black brass marker.

That's for the MilSpec (IMI) brass.

Some accumulates on the bolt face, which is easier to wipe off than the chamber interior, and requires no fixture to apply. Wear Nitrile gloves and be careful what clothing you wear, too; this stuff is forever on clothes.

For handloads using commercial brass, I do nearly the same. Solid Red with a Black Sharpie line down the center.

Years on the line shooting N/M Highpower led to a need for a quick way to tell one's brass from someone else's. The red catches the eye when picking it up, and there needs to be a fair sized area of red for it to stand out.

Load data goes on the Cartridge Box Label.

Greg

I mark the cartridge base, to keep the ink o/o the chamber.

Using a Magnum Red Marker, I swipe the entire head stamp area; then cover one half with a Black Magnum. This leaves a split red/black brass marker.

That's for the MilSpec (IMI) brass.

Some accumulates on the bolt face, which is easier to wipe off than the chamber interior, and requires no fixture to apply. Wear Nitrile gloves and be careful what clothing you wear, too; this stuff is forever on clothes.

For handloads using commercial brass, I do nearly the same. Solid Red with a Black Sharpie line down the center.

Years on the line shooting N/M Highpower led to a need for a quick way to tell one's brass from someone else's. The red catches the eye when picking it up, and there needs to be a fair sized area of red for it to stand out.

Load data goes on the Cartridge Box Label.

Greg

Last edited:

As a question for you brass markers out there, does any one make an ink pad that uses a clone of the sharpie ink? I've tried 2-3 so far and have not had good results. For some reason the ink in their markers seems unique as far as I can tell.

I really just want to be able to mark the brass I knock the crimp out of.

I really just want to be able to mark the brass I knock the crimp out of.

I think this bloke has won the brass marking game.

Rubber band.

Place three sharpies in rubber band.

You'll notice they form a triangle.

Place loaded round between the 3 points.

Rotate one rev.

You now have 3 color marked brass.

R

Place three sharpies in rubber band.

You'll notice they form a triangle.

Place loaded round between the 3 points.

Rotate one rev.

You now have 3 color marked brass.

R

I think this bloke has won the brass marking game.

Nah, not until he has it load the ammo into mags automatically as well.

Yeah, I’m pretty high tech.

Note, some brass is marked with two colors to denote a separate firing of the brass.

Note, some brass is marked with two colors to denote a separate firing of the brass.

Last edited:

Yep. Everyone at the local matches know my brass by the blue mark.that is a hell of a sharpie.

The two outside bolts push the markers to opposing sides of the pvc tube. The hole in the middle is where the head of the brass is placed. The middle bolt adjusts the depth which the case sinks to. Adjusted correctly, one mark will go in the rebates portion of the rim, the other mark will go up the case. Jus adjust the markers, and the middle bolt. Stick the brass in the hole, soon it a few Times and whala

Attachments

If anyone here has a 3D printer..I found this online

Brass Marker

Hope this helps someone.

Later

Ray

Brass Marker

Hope this helps someone.

Later

Ray

I have seen people marking their cases which always made sense but I had no idea this was such a big deal. OPs idea is simple precision.

Does anyone have a quick way to color your bullet? I'm shooting a little IBS and they want you to color your bullet to identify it on target if needed.

Does anyone have a quick way to color your bullet? I'm shooting a little IBS and they want you to color your bullet to identify it on target if needed.

Similar threads

Reloading Equipment

reloading trays, brass markers, powder cups

- Replies

- 55

- Views

- 2K

- Replies

- 0

- Views

- 180

- Replies

- 3

- Views

- 277