I think this answer to the question posed by

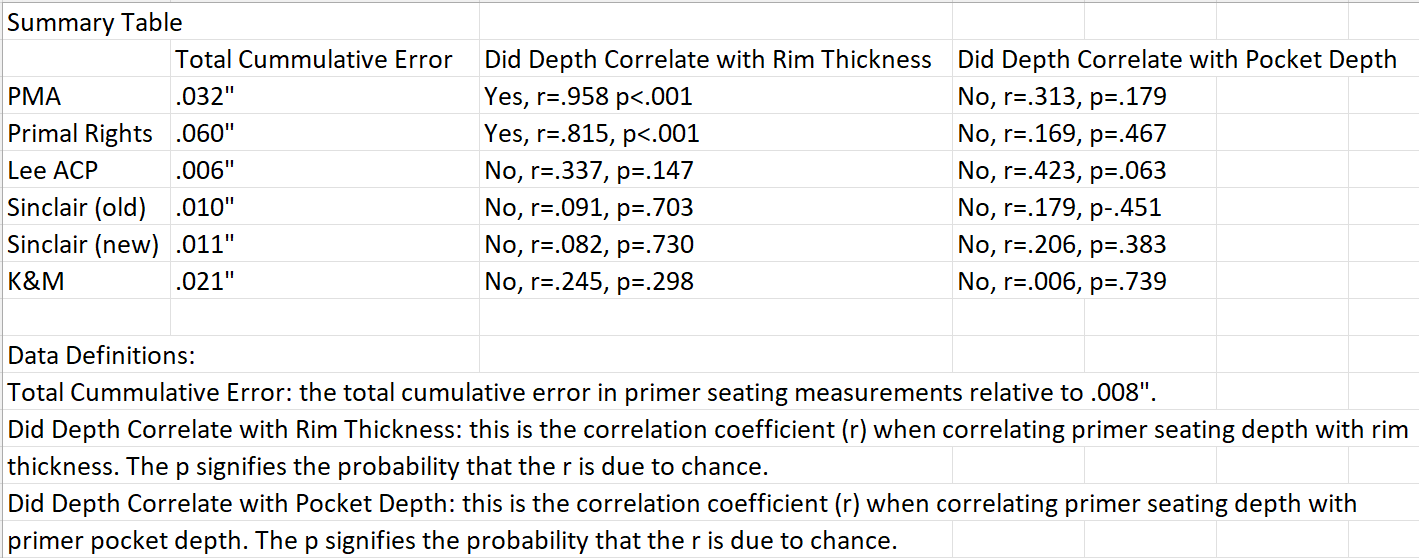

@Rio Precision Gunworks is crucial. Bryan’s research is very good and makes logical sense explaining seating depth variance. Primer seating variance is almost entirely explained by Rim Thickness for the CPS tool and probably for other similar tools. This begs the question (or research) asking which brass manufacturer produces brass with the minimum rim thickness variance. If, for example, brass X has very low variations in rim thickness, then tools like the CPS would have minimal seating depth variance.

I did a quick comparison of ten pieces of new Lapua 308 Palma brass and ten pieces of once-fired Lapua 308 Palma brass looking at rim thickness.

RIM thickness - inch

New. Once fired

1. .052 .052

2. .052 .052

3. .051 .052

4. .052 .052

5. .052 .050

6. .054 .052

7. .052 .052

8. .052 .051

9. .053 .052

10. .052 .052

Mean .0522 .0517

SD. .0008 .0007

This is just a small sample but this Lapua palma brass seemed to have a much lower SD in rim thickness than the brass Bryan used.