(This is just me documenting progress since my note book on this project has been misplaced) I've been designing and testing some trigger shoes for use with my Rifle Basix SAV-2 Trigger. I prefer not to have curved triggers on my rifles. This project of mine has been going on for a little over a year. I might as well share it with all of you. There was a discussion over on The Savage shooters forum asking about flat triggers. Thought it would be a fun project that would allow me to learn a 3D modeling program.

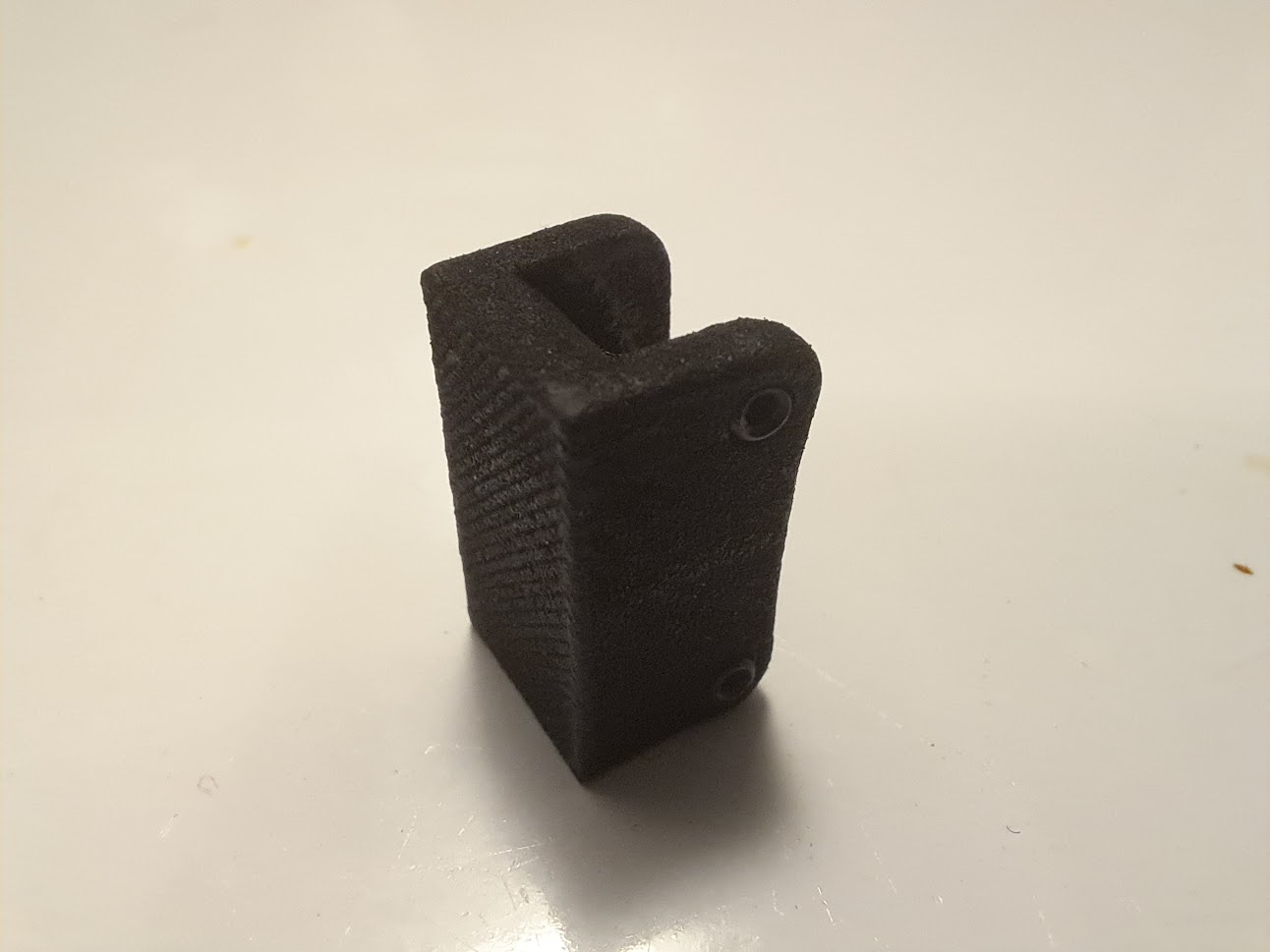

(This was the result of my first prototype that I came up with.)

(I had a friend of mine 3D print this for me (material is a mystery)

I used two 6-32 set screws to affix the shoe to the trigger. The downside to this shoe is that its very wide and the corner of the shoe dug into my finger making for not the most ergonomic feeling shoe.

I've tried to remedy this problem with a new design that will cut down on width and weight (not that it matters on a 18lb bolt gun). Its still in the design stage but ill happily share a rendering of the new design. I hope to have a 3D printed version 1 in my hands soon.

(Don't worry, the back part of the shoe is connected on one side cutting almost 0.12" off of the overall width of the shoe. I also reduced the number of set screws to hold the shoe in place by 1 further cutting down on weight. (not that it matters))

Am I wasting my time with this endeavor, or is this something that can actually be of use?

Thank you for your time to read this, it is much appreciated. -Austin

(This was the result of my first prototype that I came up with.)

(I had a friend of mine 3D print this for me (material is a mystery)

I used two 6-32 set screws to affix the shoe to the trigger. The downside to this shoe is that its very wide and the corner of the shoe dug into my finger making for not the most ergonomic feeling shoe.

I've tried to remedy this problem with a new design that will cut down on width and weight (not that it matters on a 18lb bolt gun). Its still in the design stage but ill happily share a rendering of the new design. I hope to have a 3D printed version 1 in my hands soon.

(Don't worry, the back part of the shoe is connected on one side cutting almost 0.12" off of the overall width of the shoe. I also reduced the number of set screws to hold the shoe in place by 1 further cutting down on weight. (not that it matters))

Am I wasting my time with this endeavor, or is this something that can actually be of use?

Thank you for your time to read this, it is much appreciated. -Austin