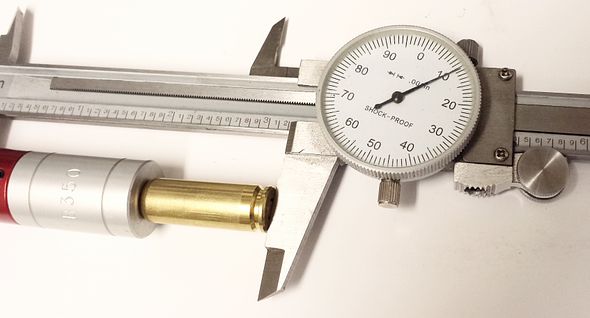

I've got a lot of 3x-4x fired Hornady 6.5CM brass where aboit 10% or so seem to have a .0015" bulge at the bottom of the web near the head that's just enough to make it stick in my Sheridan cutaway case gauge. I'm already bumping the shoulder about .003 with the Hornady FL match bushing die completely grounded out into the shell holder with a little bit of cam over, so I can't seem to size the last bit of the web where the bulge is. The sized cases that fit easily into my gauge measure .4700" whereas the "sticky" ones that wouldn't drop freely in the gauge measured .4715". I colored in the web of the case with sharpie and put it back in the gauge to prove where the high spot was and got the rub marks right below where the die sizing ends.

As for my actual chamber, the bulged ones chamber just fine with slightly more force required but not so much its a big deal (I think min reamer spec is .4714 for the web area). They seem to group more or less the same as the unbulged ones with the same load. I flame anneal all my brass before every resize. I use imperial sizing wax for lube and have never had a stuck case.

I've read this can be a sign of overpressure but I have a REALLY hard time believing that. My match load is nowhere near max (140gr RDF, 43.5gr StaBall65, CCI 200 @2750fps). The cases showed ZERO other signs of pressure. No primer cratering or flattening out. No loose primer pockets. No hard extraction.

I don't really wan't to toss brass that's only had 3x-4x loadings, especially when they still chamber and shoot more or less the same as other brass, but I can't really figure out why I can't get them to size like all the other brass to the point they'll drop in my gauge unassisted.

Any ideas what's going on? Am I gonna have to shave down my shell holder to get my FL sizer to actually size the whole damned case?

As for my actual chamber, the bulged ones chamber just fine with slightly more force required but not so much its a big deal (I think min reamer spec is .4714 for the web area). They seem to group more or less the same as the unbulged ones with the same load. I flame anneal all my brass before every resize. I use imperial sizing wax for lube and have never had a stuck case.

I've read this can be a sign of overpressure but I have a REALLY hard time believing that. My match load is nowhere near max (140gr RDF, 43.5gr StaBall65, CCI 200 @2750fps). The cases showed ZERO other signs of pressure. No primer cratering or flattening out. No loose primer pockets. No hard extraction.

I don't really wan't to toss brass that's only had 3x-4x loadings, especially when they still chamber and shoot more or less the same as other brass, but I can't really figure out why I can't get them to size like all the other brass to the point they'll drop in my gauge unassisted.

Any ideas what's going on? Am I gonna have to shave down my shell holder to get my FL sizer to actually size the whole damned case?