I have an Area 419 hellfire match break I need to install. After reading some threads It seems like most folks dont use any thread locker on breaks but they also frequently swap the break with a direct thread silencer. I guess it would also be easier to remove for cleaning with no thread locker involved. Still trying to learn the nuances of building a long range precision bolt gun.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is there a consensus re: thread locker on breaks? In what scenarios should it be used on a bolt gun? I don’t have a silencer (live in CA)

- Thread starter WeR0206

- Start date

Rocksett is better. It's made for heat resistance.

Kind of expensive, but as long as you keep the cap on it, and keep it stored inside (room temp) that bottle will last you for decades...

Rocksett

Kind of expensive, but as long as you keep the cap on it, and keep it stored inside (room temp) that bottle will last you for decades...

Rocksett

I used to run a brake with a minimal drop of blue loctite. Just enough to keep it in place. Then as tight as I could get the brake with a wrench by hand just holding the rifle between my legs on the floor and holding the wrench close to the barrel

Never had one come loose and would remove every time I cleaned the barrel and cleaned the crown as well

Never had one come loose and would remove every time I cleaned the barrel and cleaned the crown as well

I was thinking rocksett as well.Rocksett is better. It's made for heat resistance.

Kind of expensive, but as long as you keep the cap on it, and keep it stored inside (room temp) that bottle will last you for decades...

Rocksett

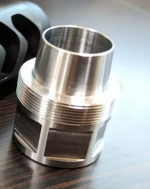

Since the hellfire match break uses a universal adapter that threads on first, I was thinking of using rocksett to install that, let it set, then screw on the break without any thread locker of if anything a smidge of blue loctite or orange permatex so it can be removed easily for cleaning etc.

Rocket the uni adaptoroin the muzzle, just the smallest drop. Leave the brake to adaptor dry.I was thinking rocksett as well.

Since the hellfire match break uses a universal adapter that threads on first, I was thinking of using rocksett to install that, let it set, then screw on the break without any thread locker of if anything a smidge of blue loctite or orange permatex so it can be removed easily for cleaning etc.

It is a coned interface and the brake will hold itself on plenty securely.

Just use loctite 242 on the barrel thread. Heat wont be an issue, and you still have full access to the crown for cleaning. If you do need to remove it for some reason, it will come off with no fuss.I have an Area 419 hellfire match break I need to install. After reading some threads It seems like most folks dont use any thread locker on breaks but they also frequently swap the break with a direct thread silencer. I guess it would also be easier to remove for cleaning with no thread locker involved. Still trying to learn the nuances of building a long range precision bolt gun.

Never an issue wih the 419 adapter wrenched on as they suggest with no thread locker.I was thinking rocksett as well.

Since the hellfire match break uses a universal adapter that threads on first, I was thinking of using rocksett to install that, let it set, then screw on the break without any thread locker of if anything a smidge of blue loctite or orange permatex so it can be removed easily for cleaning etc.

Blue loctite (242, 243) isn't heat-resistant and is only a Placebo in this application.

I've been running a Hellfire brake for years with no thread lock without issue. It never comes loose. The adapter doesn't have large flat areas to grip on when you install or remove it so I wouldn't get to generous with any thread lock. You may end up taking it off with a pipe wrench and a propane torch.

Good point re: lack of large flat areas. I guess Ill keep it simple and not use any thread locker and see how it goes (this will give me easy access to clean the crown/break as well). If I do end up using some Ill have to make sure to only hand tighten/not torque it down too much or itll be a PITA to get off without large wrench flats.I've been running a Hellfire brake for years with no thread lock without issue. It never comes loose. The adapter doesn't have large flat areas to grip on when you install or remove it so I wouldn't get to generous with any thread lock. You may end up taking it off with a pipe wrench and a propane torch.

242 is good to 300 degrees. In a bolt gun application, its plenty resistant.Blue loctite (242, 243) isn't heat-resistant and is only a Placebo in this application.

I've been playing with precision rifle for eight years and five different centerfire rifles, and I've had a brake come loose exactly once... and it was my fault for getting distracted while cleaning the rifle and not tightening down the lock nut correctly.

I cannot imagine gunking up my muzzle threads with any sort of thread locker....

I cannot imagine gunking up my muzzle threads with any sort of thread locker....

In suppressed application where the can threads over a brake, removing the can (hot or carbon locked) sometimes takes the muzzle device with it, and now its stuck in the can. Thread locker, whether its 242, 271, or rocksett, protects against this. Perhaps most importantly, it relieves the need to torque the shit out of the muzzle device, which can hurt accuracy.I've been playing with precision rifle for eight years and five different centerfire rifles, and I've had a brake come loose exactly once... and it was my fault for getting distracted while cleaning the rifle and not tightening down the lock nut correctly.

I cannot imagine gunking up my muzzle threads with any sort of thread locker....

I have 2, 419 Sidewinder brakes on 6.5 creed and 300 PRC barrels. Both were attached per 419's recommended torque values and it's never been a problem including with the silencer adaptor.

I have my high volume 5.56 rifle silencer adaptors rockset on, but as mentioned above that is more like insurance for if the can gets stuck.

I have my high volume 5.56 rifle silencer adaptors rockset on, but as mentioned above that is more like insurance for if the can gets stuck.

I've heard of at least one scenario where a stainless brake galled onto a stainless barrel. I throw a little grease on the threads if it's not a suppressor mount. If it's for a suppressor then I do a drop of rocksett instead. I would not go over 10-15 ft/lbs of torque, I have been told that too much torque on the threads can begin to compress the barrel and choke the bore.

Thanks for the tip. Since Im not using a suppressor I was curious about using grease.I've heard of at least one scenario where a stainless brake galled onto a stainless barrel. I throw a little grease on the threads if it's not a suppressor mount. If it's for a suppressor then I do a drop of rocksett instead. I would not go over 10-15 ft/lbs of torque, I have been told that too much torque on the threads can begin to compress the barrel and choke the bore.

I've learned something new. Thanks for this!In suppressed application where the can threads over a brake, removing the can (hot or carbon locked) sometimes takes the muzzle device with it, and now its stuck in the can. Thread locker, whether its 242, 271, or rocksett, protects against this. Perhaps most importantly, it relieves the need to torque the shit out of the muzzle device, which can hurt accuracy.

Torque spec for 5/8-24 @ 25 ft lbs per Area 419,Universal Adapter Torque Spec to barrel is 25 FT LBs

because you are supposed to use anti-seize.

Just RTFM and don't over-complicate it.

That's pretty much what it boils down to. I guess I opened a can of worms with this thread...Just RTFM and don't over-complicate it.

Nope, you really didn't. You asked a question, and people answered according to their own frames of experience/knowledge. That's what I did... and got respectfully schooled by @Supersubes . I learned something, and hopefully you got your question answered.That's pretty much what it boils down to. I guess I opened a can of worms with this thread...

Last edited:

On AR15's you can torque a muzzle device up to 35 ft/lbs. I'm not sure i've ever heard anyone call for a higher torque spec.

When properly torqued, short of carbon locking a suppressor on, I cannot imagine a scenario where your muzzle device is going to come off.

Is there any general consensus on barrel torque for precision guns? I would imagine even 15 ft lbs would be sufficient to hold a muzzle brake on through some pretty rough and tumble action.

When properly torqued, short of carbon locking a suppressor on, I cannot imagine a scenario where your muzzle device is going to come off.

Is there any general consensus on barrel torque for precision guns? I would imagine even 15 ft lbs would be sufficient to hold a muzzle brake on through some pretty rough and tumble action.

I've never understood why they don't do this. It's the main reason I no longer use them.he adapter doesn't have large flat areas to grip on when you install or remove it

Yes it has a hex on the front like bolt, it's just skinny. It has never caused an issue and hasn't rounded off so I guess it's enough. I don't see any need to loctite it, I think I used a little anti seize when I installed them.It has a hex on the front of it though?

Using a flank-drive style box wrench or socket, those 5/8 (16mm) wrench flats are fine. Automotive and industrial applications use this wrench atmore than double the 25 ft/lb we are talking here (see: grade 8 , fine thread , 7/16 flange bolt for reference)

For the AI/Sako crowd, for the m18 threaded barrels, there is a differnt type of adapeter. On the "type 2" adapter, the wrench flats are behind the external threads, so you can't use box or socket type wrenches. That one is more of a PITA...

For the AI/Sako crowd, for the m18 threaded barrels, there is a differnt type of adapeter. On the "type 2" adapter, the wrench flats are behind the external threads, so you can't use box or socket type wrenches. That one is more of a PITA...

Attachments

242 requires heat in excess of 482 F to release where hand tools do not work per their TDS. If you're letting your barrel get that hot, you must have stock in Bartlein...Blue loctite (242, 243) isn't heat-resistant and is only a Placebo in this application.

I use Rocksett where I have less than what I normally consider to be adequate torque shoulder on the barrel. Threads bring the parts together- shoulders align them. If I have concern about deforming the shoulder from torque, I'll use Rocksett to be sure the alignment is maintained and the muzzle device can't vibrate loose.

Perfectly faced shoulders on the brake and barrel shoulder will "hold" extremely well. Anyone here who's installed them knows you can "wring" a brake onto the shoulder with your fingertips- and you'll need a wrench to get it off. All that said, I put a drop of 242 on my own because it can't hurt...

JMOYMMV.

Similar threads

- Replies

- 2

- Views

- 778

- Replies

- 30

- Views

- 6K

- Replies

- 24

- Views

- 1K

- Replies

- 16

- Views

- 3K