I present:

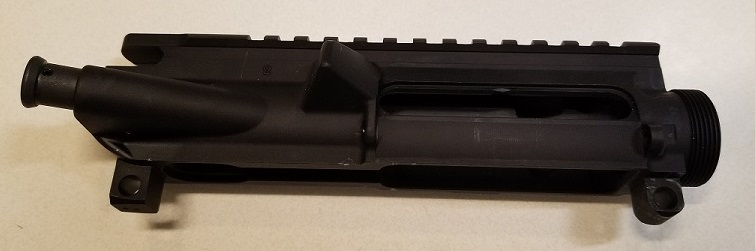

Exhibit A (BCM Blem)

Exhibit B (ARP CLE 12.5")

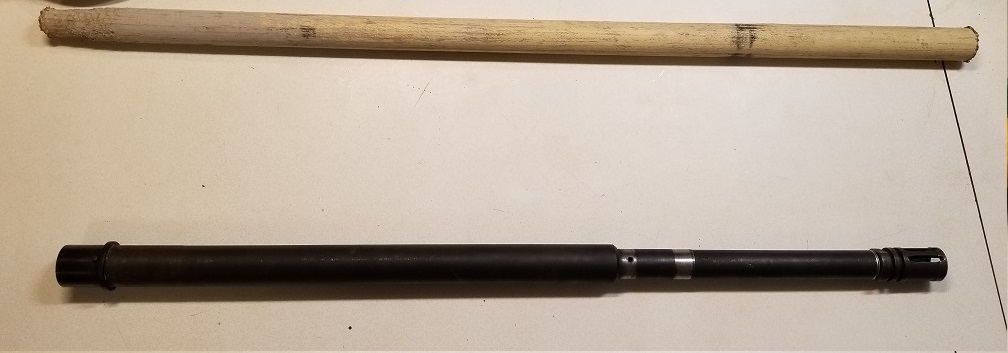

Exhibits FC and WW,CD (repurposed stick o wood/dowel and unloved Olympic Arms barrel)

So I had the ARP barrel in the freezer for a good 4 days.

I assembled the upper (door removed since) tried to true the receiver face but the Brownells receiver lapping tool wouldn't slide in. Maybe I wasn't using the proper finesse.

Anyway I said fuck it, lets assemble it. That was at about 3:00 AM after being woken up to perform a chore.

After using a heat gun, I failed to get my barrel in (insert That's What She Said joke here). Heated again, finally got it in, but didn't get the pin aligned.

Fuck me.

So I tried hammering with a rubber mallet using the dowel (Exhibit Fail City), while the upper was still a bit toasty, but got nowhere. The dowel had been recommended and successful in non-thermal fitting barrel removal duty, to break the Loctite seal, etc. Trash can under barrel to catch it.

I tried again today, with feeling. Still no luck. I had been contemplating what bar stock or metal I had. Then I remembered the "shot out" Olympic Barrel (Exhibit Winner Winner, Chicken Dinner) that a buddy gave me after he replaced it with a Larue. At first I am like I might need to remove the MD, but no, stupid, thats narrower and you expose the threads to the upper. I double checked and it was seating nicely.

Sure enough after 5 blows it was starting to move and I got it out.

Hot damn. I was able to put that Olympic barrel to a good purpose, and now I have another tool in my arsenal and remove a thermal fitted barrel much quicker in the future.

The ARP barrel is back in the freezer.

I really need to look again and see why the receiver facing tool didn't seat in the upper.

And clean up some splinter debris out of the upper and barrel.

Exhibit A (BCM Blem)

Exhibit B (ARP CLE 12.5")

Exhibits FC and WW,CD (repurposed stick o wood/dowel and unloved Olympic Arms barrel)

So I had the ARP barrel in the freezer for a good 4 days.

I assembled the upper (door removed since) tried to true the receiver face but the Brownells receiver lapping tool wouldn't slide in. Maybe I wasn't using the proper finesse.

Anyway I said fuck it, lets assemble it. That was at about 3:00 AM after being woken up to perform a chore.

After using a heat gun, I failed to get my barrel in (insert That's What She Said joke here). Heated again, finally got it in, but didn't get the pin aligned.

Fuck me.

So I tried hammering with a rubber mallet using the dowel (Exhibit Fail City), while the upper was still a bit toasty, but got nowhere. The dowel had been recommended and successful in non-thermal fitting barrel removal duty, to break the Loctite seal, etc. Trash can under barrel to catch it.

I tried again today, with feeling. Still no luck. I had been contemplating what bar stock or metal I had. Then I remembered the "shot out" Olympic Barrel (Exhibit Winner Winner, Chicken Dinner) that a buddy gave me after he replaced it with a Larue. At first I am like I might need to remove the MD, but no, stupid, thats narrower and you expose the threads to the upper. I double checked and it was seating nicely.

Sure enough after 5 blows it was starting to move and I got it out.

Hot damn. I was able to put that Olympic barrel to a good purpose, and now I have another tool in my arsenal and remove a thermal fitted barrel much quicker in the future.

The ARP barrel is back in the freezer.

I really need to look again and see why the receiver facing tool didn't seat in the upper.

And clean up some splinter debris out of the upper and barrel.

Last edited: