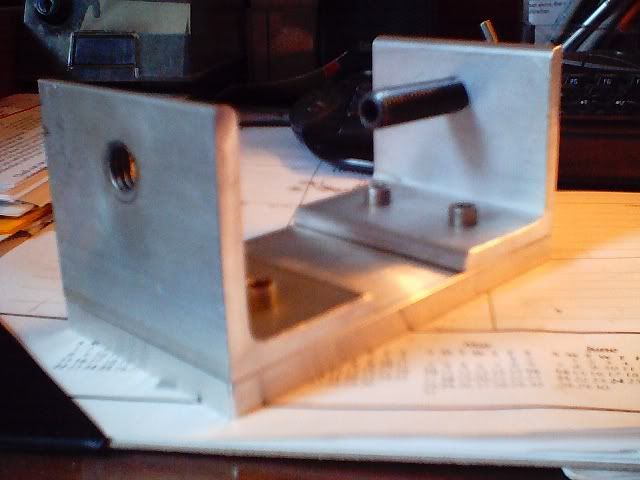

Final fixture here, It is made of 1/4" 6061 T6 flat plate with angle bolted to it. Everything else was trial and error junk

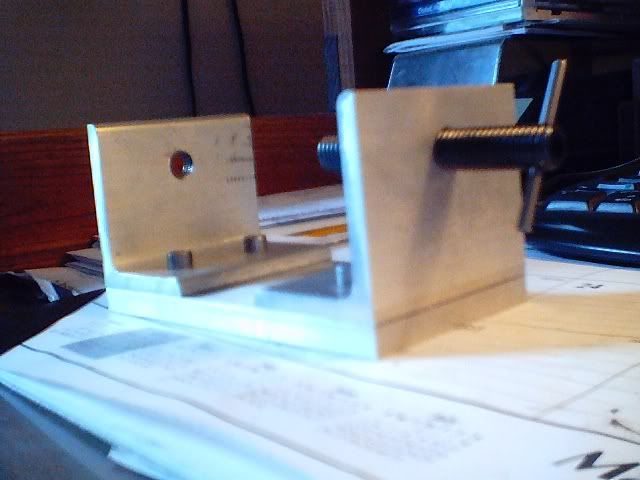

I made my own because I'm a cheap ass. It's really simple, I used two pieces of 2"x4"x1/8" aluminum angle from my shop, some scrap wood, and a piece of 1/2" all-thread. Cut the angle about 2 inches wide and drill a 1/2" hole on the ends. Drill a hole slightly larger than the firing pin head in the end of the all-thread and run a countersink on the hole to bevel the edge. Then I screwed to the angles to the wood for a base and set it up by putting the firing pin assembly in one end and tightening it down with a washer and a nut. Then slip the all-thread in the other end and slide the firing pin tip into the hole. I used two nuts to tighten and loosen pressure on the spring . It is long enough to do short and long action pins

I made my own because I'm a cheap ass. It's really simple, I used two pieces of 2"x4"x1/8" aluminum angle from my shop, some scrap wood, and a piece of 1/2" all-thread. Cut the angle about 2 inches wide and drill a 1/2" hole on the ends. Drill a hole slightly larger than the firing pin head in the end of the all-thread and run a countersink on the hole to bevel the edge. Then I screwed to the angles to the wood for a base and set it up by putting the firing pin assembly in one end and tightening it down with a washer and a nut. Then slip the all-thread in the other end and slide the firing pin tip into the hole. I used two nuts to tighten and loosen pressure on the spring . It is long enough to do short and long action pins