I've found 'Sameness' and Sensitivity being about as important as absolute Accuracy.

The long term Sameness is what most like about beam scales. As long as they are in good repair they will last a 100 years

Dirty knife edges or whatever is used for the poise will affect Sensitivity. Loss of Sensitivity makes all charges look the same.

Approaching the target weight from above and below by adding or removing a very small amount of the target is a good test of sensitivity.

With any precision device, temperature (even temperature compensated laboratory balances) can effect measurement Accuracy.

Allowing the device to stabilize to a constant temperature can help over one reloading session. If it's the SAME temperature as last time all the better.

Electronic scales have gotten a bad rap. Having a digital scale that barely has the resolution for weighing powder allows a count (or two) of auto zero, a count or two of linearity, even when CALIBRATED, and a count or two of electronic noise at the target weight. Most vendors will supply you with a Calibration weight that usually isn't anywhere near your target powder charge. What cartridge takes a 50 gram charge?

Most scale manufacturers will pick a calibration point that provides the best linearity over the entire range. That weight is needed but it might not suit your application. In addition most are supplied with chrome plated magnetic steel cal weights.

Non-magnetic (or nearly so) cal weights are better. You would be surprised how much some locations are saturated with electric fields.

My suggestions (not only can I spell Metrologist, I was one

) are as follows:

Purchase at least 3 good calibration weights (you might already have an acceptable one for full scale calibration).

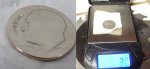

Get one that is close to your primary charge weight.

Load powder to something around 25 to 30grains, get a 2 gram weight.

Load to 50grains, get a 3 gram weight. Those will check your scale, beam or electronic, close to your target.

Either is better than trusting a 50 gram calibration weight and you can get by with just one.

Now, get a 'Sensitivity' calibration weight,

If you think you are throwing charges to +/- 0.1 grains, prove it with a 0.1 grain sensitivity weight.

(5 milligram would be good for +/- 0.1 grain, 1 milligram for those OCD that weight each charge to 0.02 grains

).

There's no need for lab standard weights, just good quality. If protect them they will also last 100 years.

If you calibrate a digital scale at 50 grams and notice that the calibration is not linear at your target weight, fudge the 50gram calibration a little.

You can Zero will a small bit of paper, cal at 50 plus the paper and it will read a little high at 50grams. That should raise the reading at 3 grams if needed. Or, zero then add the 50gram cal weight and a small piece of paper. Now the scale will read low at 50 and lower at 3 grams.

You can't tell if you don't have a target cal weight though.

Use the sensitivity weight to verify the scale can sense a small change. 3grams should be 3 grams (46.3grains) and the 3 grams plus the 1 milligram sensitivity weight should now indicate 3.001grams (46.45grains or the rounded up or down even number).

I know, numbers and math make it harder than necessary

A hint with digital scales is to tare with the container you use to toss with but EVERYTIME you remove it look at the weight displayed of that container. It will show as a negative value but if it does not settle to the same value each and every time the scale will need to be tared again and the last charge might be suspect.

Watch out for scales that advertise +/- 0.1 grain accuracy but only indicate even numbers

Some electronic scales use Al Gorithms to display some units. Use conversion factors and your cal weights to find the unit that your scale measures best at.

I have one that changes range and goes from 0.001gram to 0.002 grams but still displays to the nearest 0.005 Carats.

A fairly easy conversion.

Crap, that was long.