For what its worth, new guy here but Ive been lurking for a long time. Pretty active on the "other" site for a long time

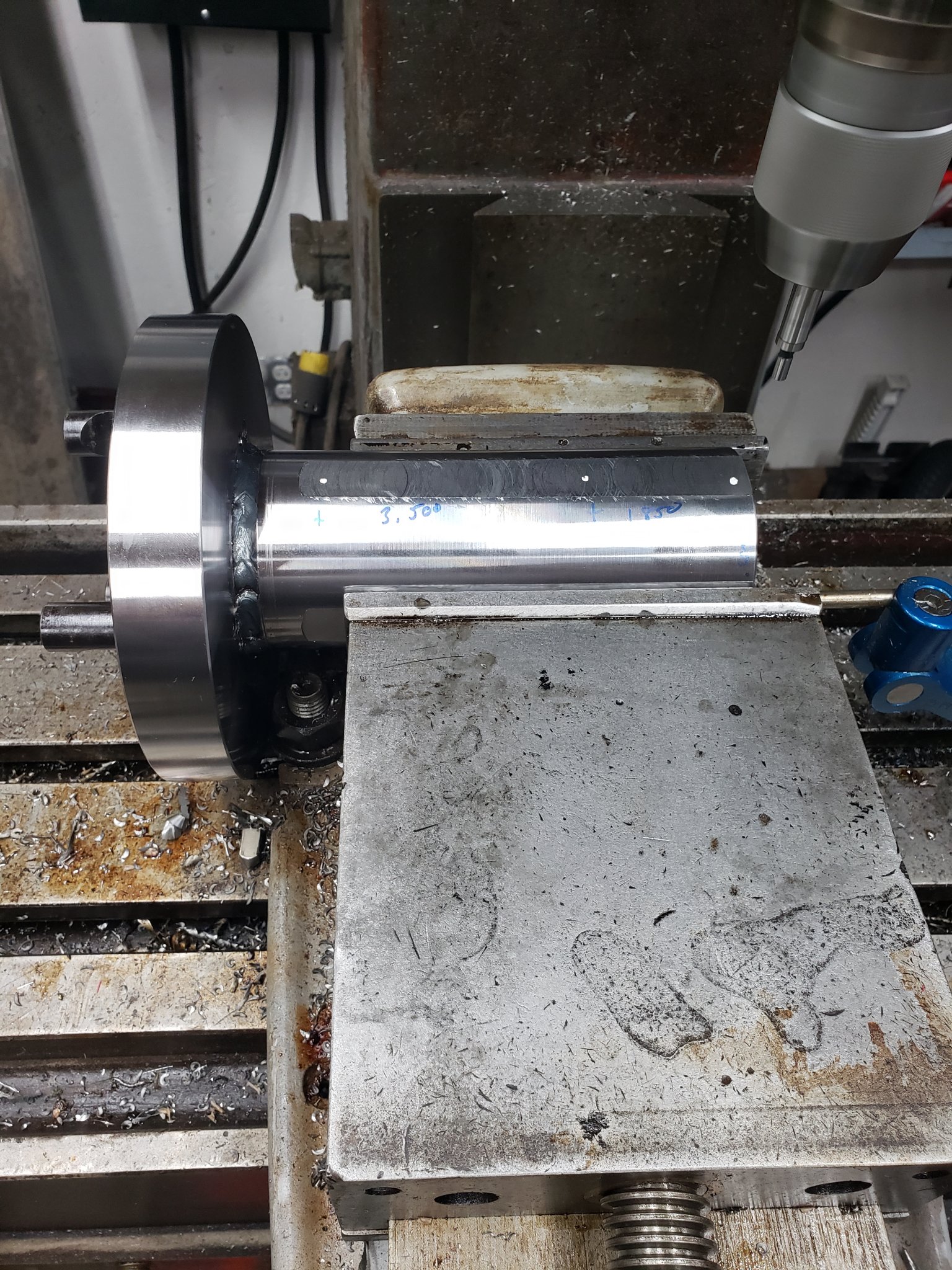

Since getting into PRS Ive been doing some of my own work in my shop. I was using a shop built chamber fixture. Basic steel heavy wall tube bored out, 4 jaw style. Since my 14x40 lathe head stock is pretty long, getting anything short like an AR barrel in there proves difficult for using the rear spider and the four jaw.

I havnt seen any kind of this fixture on line, albeit I didnt look real hard. I was growing tired of loading the fixture into the 4 jaw, indicating it in, then loading the pipe im working on and spending 45 mins to indicate the bore in. So I removed one of those steps

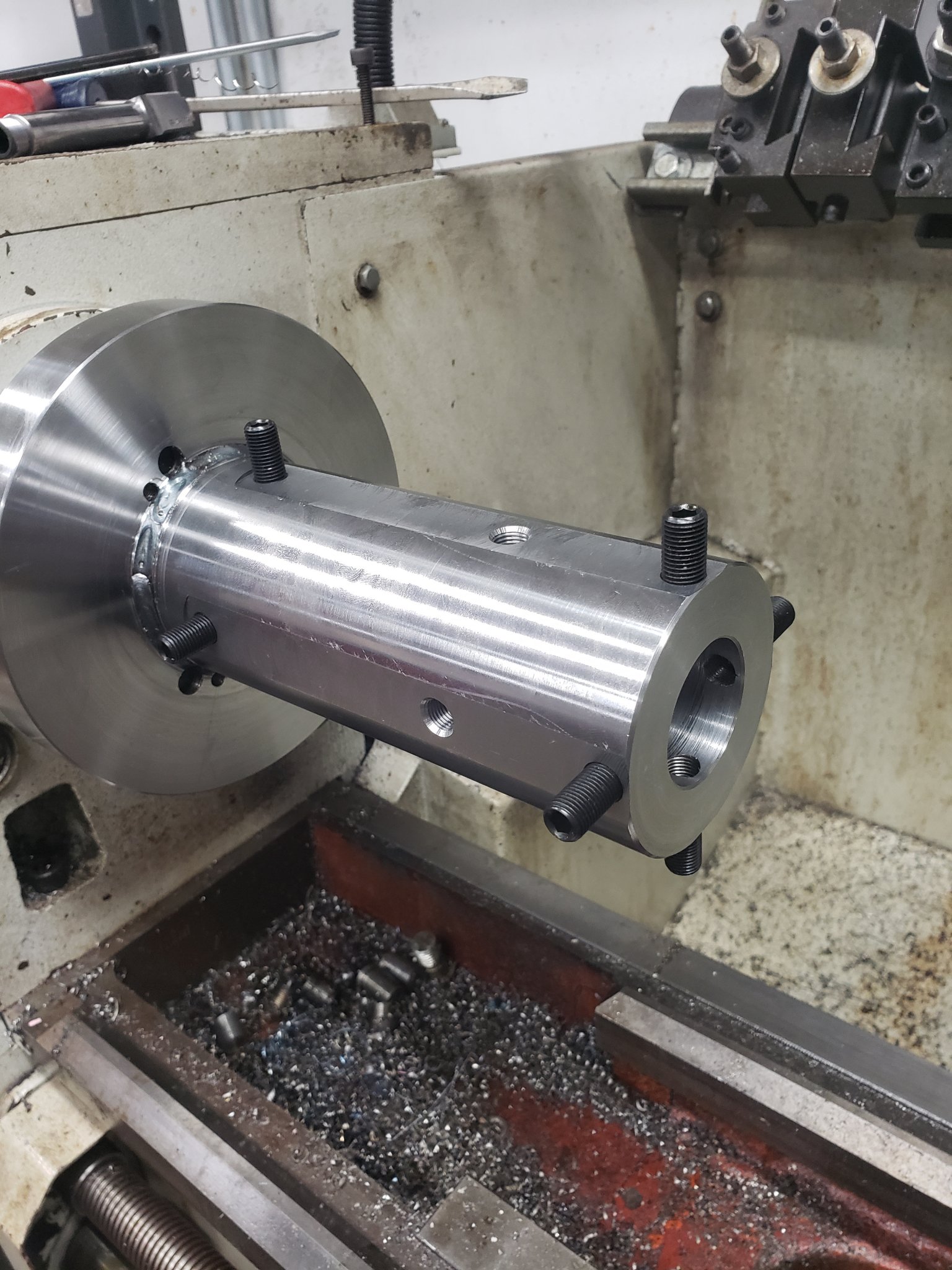

I picked up a D1-4 steel backplate, turned it down, cut a weld prep on my bar stock and cooked in a nasty hot bead. I then turned the fixture down to my wanted dimensions. Went to the mill to get some flats, and a series of 3/8X24 holes for my jack bolts. (brass tipped set screws)

Lining up my witness marks on my single and the backplate/fixture Im getting repeatable <.001 runout on the fixture bore itself

Pros

Fast ... cam lock it on and im ready to indicate in my bore

Allows me to "8 point" indicate parts that are too short to run through my headstock (rear spider and front 4 jaw chuck)

its short, and tight up to the spindle to maintain rigiity. Anytime I was using my traditional fixture in my 4 or 6 jaw, it would end up hanging almost 30 inches out from the spindle after considering the depth of whatever chuck it was in ..

adding another set of jack screws I can indicate pistol barrels now

Cons

cost - back plate was close to $200

Since getting into PRS Ive been doing some of my own work in my shop. I was using a shop built chamber fixture. Basic steel heavy wall tube bored out, 4 jaw style. Since my 14x40 lathe head stock is pretty long, getting anything short like an AR barrel in there proves difficult for using the rear spider and the four jaw.

I havnt seen any kind of this fixture on line, albeit I didnt look real hard. I was growing tired of loading the fixture into the 4 jaw, indicating it in, then loading the pipe im working on and spending 45 mins to indicate the bore in. So I removed one of those steps

I picked up a D1-4 steel backplate, turned it down, cut a weld prep on my bar stock and cooked in a nasty hot bead. I then turned the fixture down to my wanted dimensions. Went to the mill to get some flats, and a series of 3/8X24 holes for my jack bolts. (brass tipped set screws)

Lining up my witness marks on my single and the backplate/fixture Im getting repeatable <.001 runout on the fixture bore itself

Pros

Fast ... cam lock it on and im ready to indicate in my bore

Allows me to "8 point" indicate parts that are too short to run through my headstock (rear spider and front 4 jaw chuck)

its short, and tight up to the spindle to maintain rigiity. Anytime I was using my traditional fixture in my 4 or 6 jaw, it would end up hanging almost 30 inches out from the spindle after considering the depth of whatever chuck it was in ..

adding another set of jack screws I can indicate pistol barrels now

Cons

cost - back plate was close to $200